Key areas

Health Care

Testing solutions for medical technology, pharmaceuticals & diagnostics

Optical quality inspection in medical technology, pharmaceuticals & diagnostics

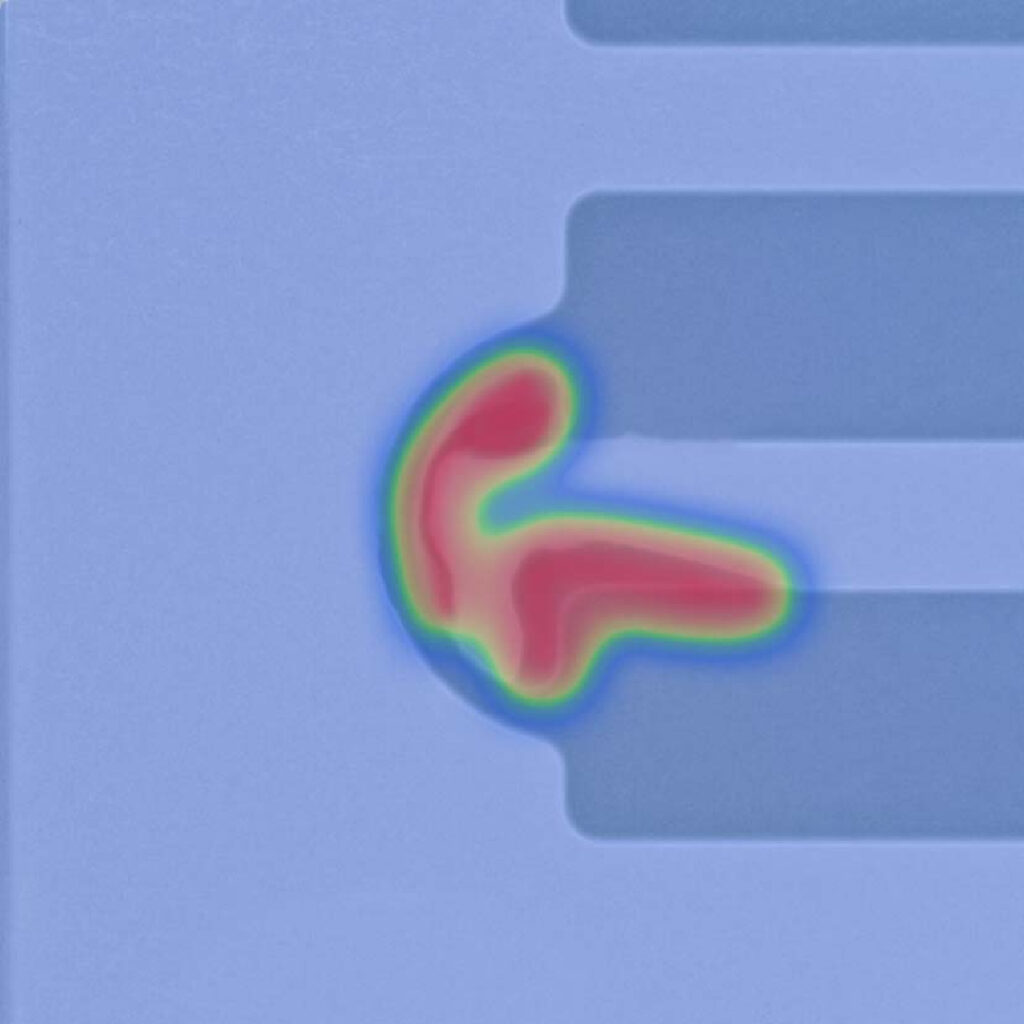

Healthcare is a strong growth market and is considered by Germany and Europe to be one of the key technologies of the future. Product development and production scaling place the highest demands on quality requirements to detect common defects such as inclusions, cracks, defects, deformations, component placement errors, punctures, burrs, and contamination. Our machine vision solutions and inspection systems are specialized in detecting these errors and defects in medical injection-molded parts, miniaturized sensors, microfluidic systems, tubing, and packaging

Inspection. In addition to classic testing criteria, we rely on AI-supported algorithms to detect anomalies microscopically and macroscopically. Our code reading module enables the rapid, parallel scanning of a large number of matrix codes and barcodes. With our MV.SENSE and INLINE.SECTOR systems, we can non-destructively test layer thicknesses and wall thicknesses of barrier layers and hoses during the process. We build our systems as stand-alone versions or as integrated solutions for your automated production environment.

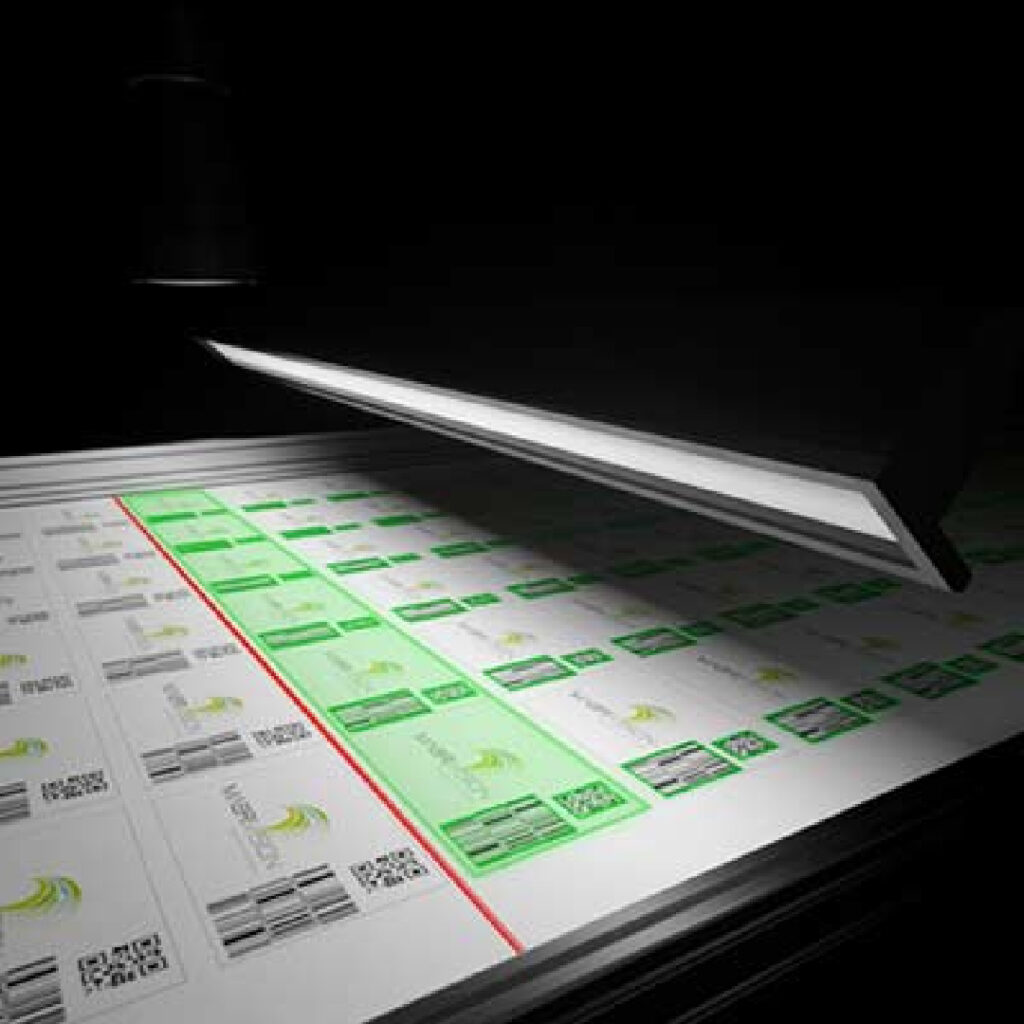

Matrix code check

Our code-reading software module is optimized for fast, high-content code throughput reading tasks

AI packaging inspection

With our machine vision platform MV.IMAGING, we develop AI solutions for the rapid detection of defects on packaging.

Hose test

With our INLINE.SECTOR, we have developed a process that enables non-destructive inline testing of the wall thicknesses of medical tubes – without X-rays or ultrasound.

Barrier layers

Barrier layers made of EVOH minimize unwanted diffusion through the material. Our testing technology enables non-destructive testing of barrier layers and detection of defects.

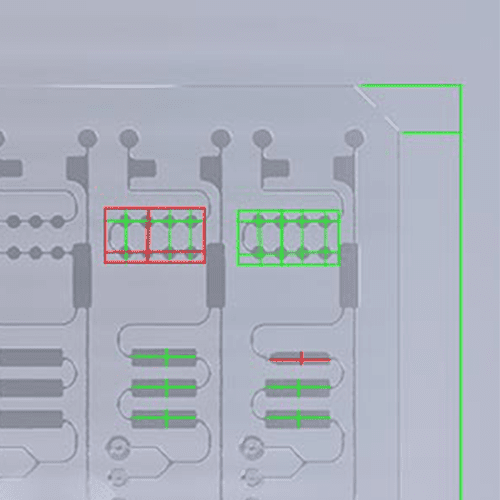

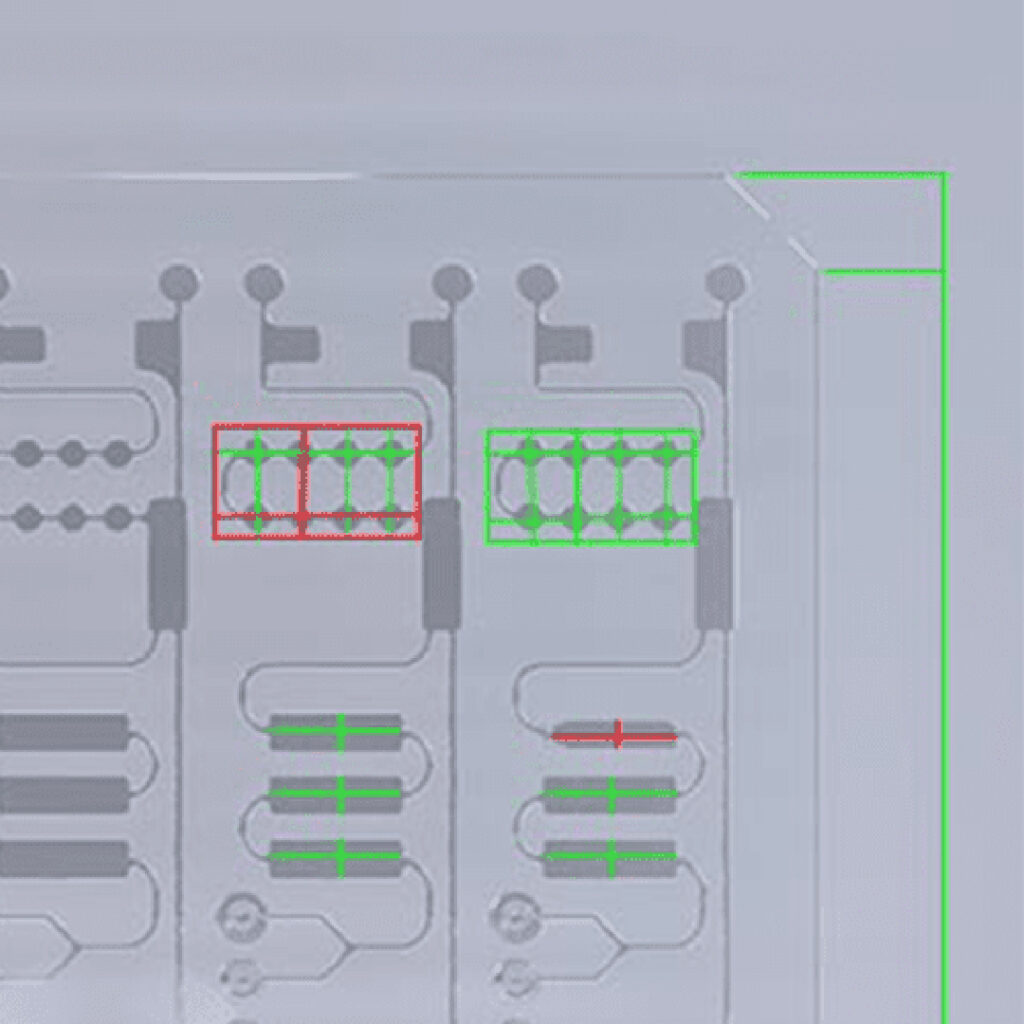

Microfluidics

Our testing systems solve the challenges encountered in the large-scale production of microfluidic systems and lab-on-a-chip applications.

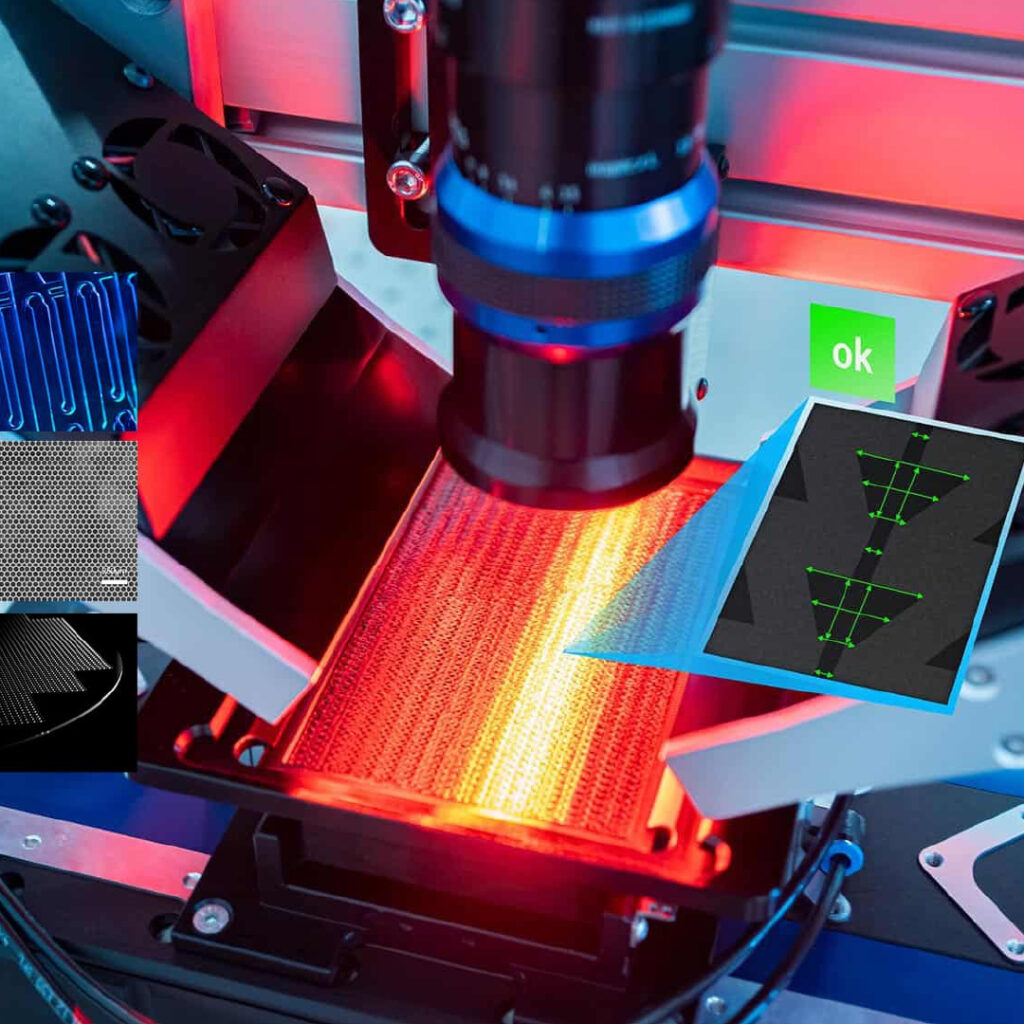

miniaturized sensors

The production of miniaturized sensors requires the measurement of features down to the micrometer level. Our testing systems and high-speed microscopes can capture these properties even under production conditions.

Optical inspection systems for healthcare applications from MABRI.VISION

End-to-end turnkey solutions

We build turnkey testing systems for our customers. From the initial concept and all necessary qualification steps to ongoing service, we offer a complete solution from a single source. Together with our customers, we design efficient testing processes that integrate seamlessly into their production.

Software and hardware automation

Through collaboration with our partners, our team has gained experience in process and plant qualification. Our software offers essential modules necessary for qualification.

Precision and speed

We carefully design our systems according to the needs of our customers and their testing processes. Our goal is to achieve an optimal balance between precision and speed. To this end, we rely on parallelization and innovative technologies such as TDI, OCT, and AI.

What do we test?

Dimensional accuracy

Machine Vision

Anomalies | Defects

Codes | OCR

layers

Testing solutions for electronic components

Discover our product portfolio

MV.CHECK Inspection Systems

Machine Vision: MABRI.VISION develops and builds machine vision inspection systems and solutions for your production processes.

Rotary indexer test systems

Our rotary indexing testing systems for quality assurance of your products are characterized by the combination of various technologies.

High-speed microscope - Automated testing

MABRI.VISION offers an inline-capable and cycle-time-neutral high-speed microscope for the automated inspection of microstructured components.

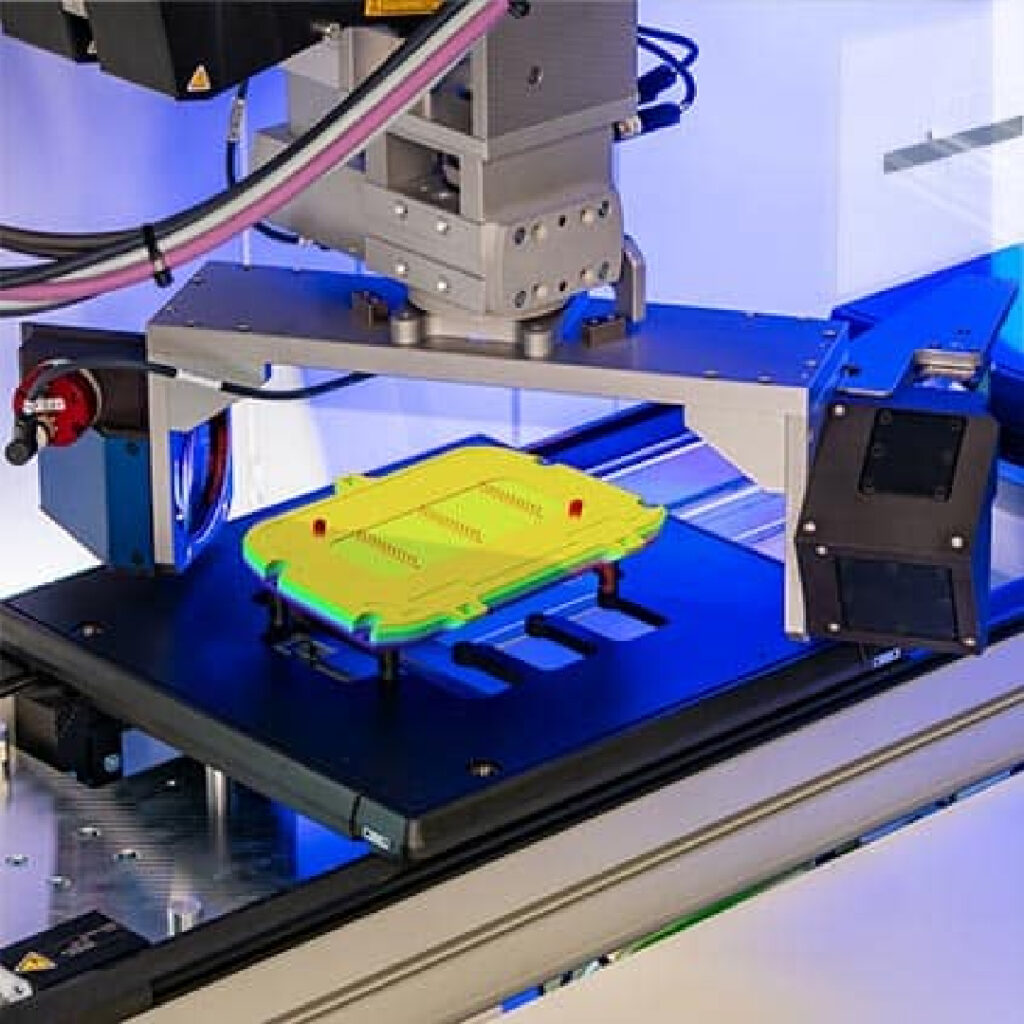

Inline 2D/3D measurement on the product carrier

We offer 2D/3D measurement on the workpiece carrier for your quality assurance with our MV.EYE i2 WT inspection system. Seamless and directly on the workpiece carrier.

Interested?

We'll call you back!

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision