Key areas

Miniaturized components

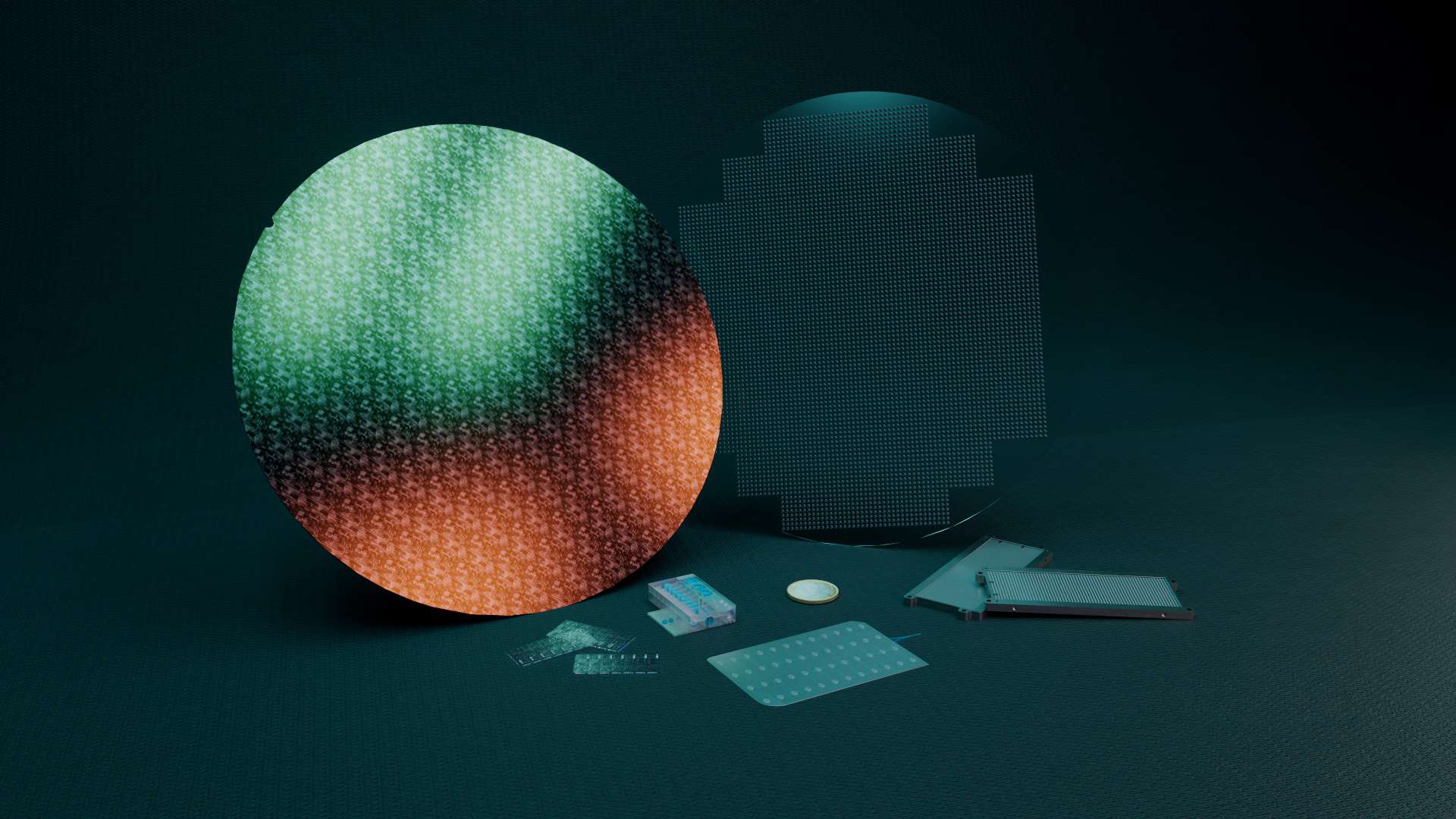

Testing solutions for microtechnology

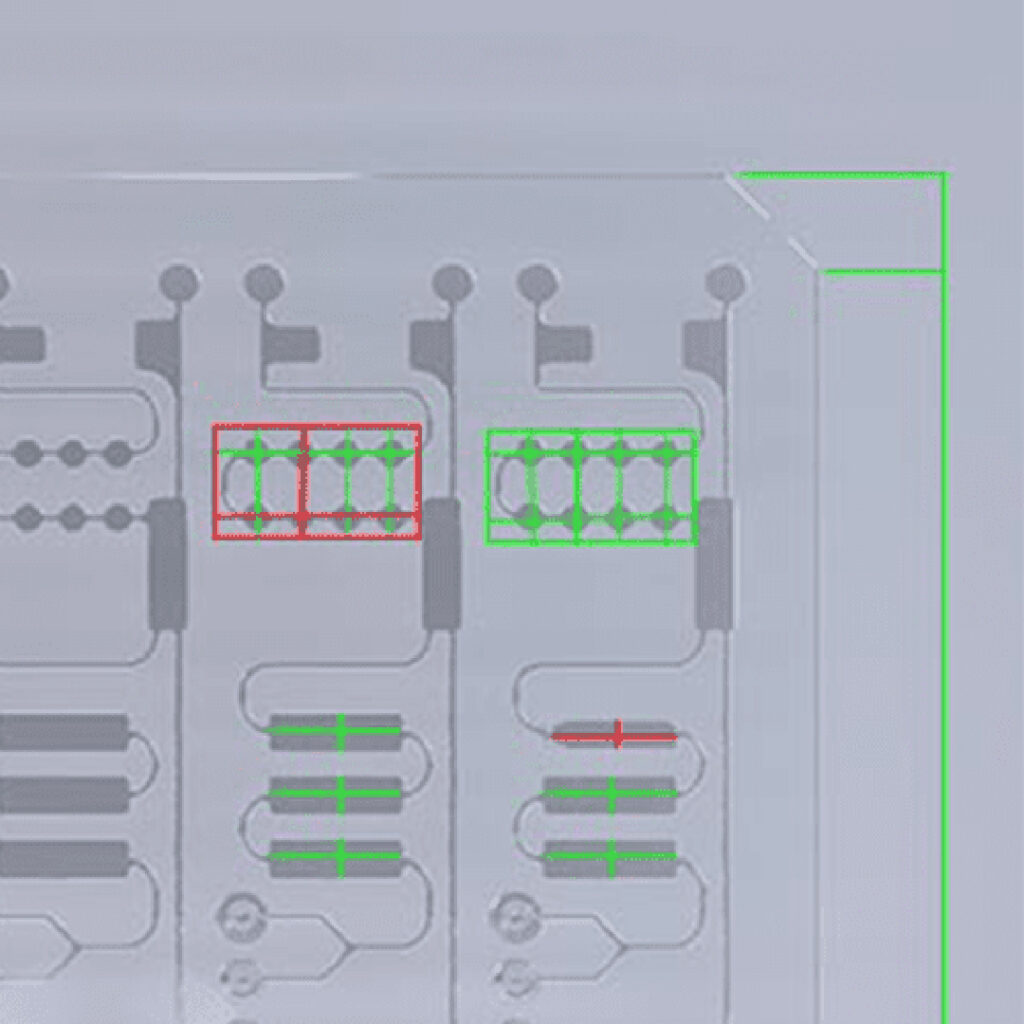

Quality inspection of miniaturized components

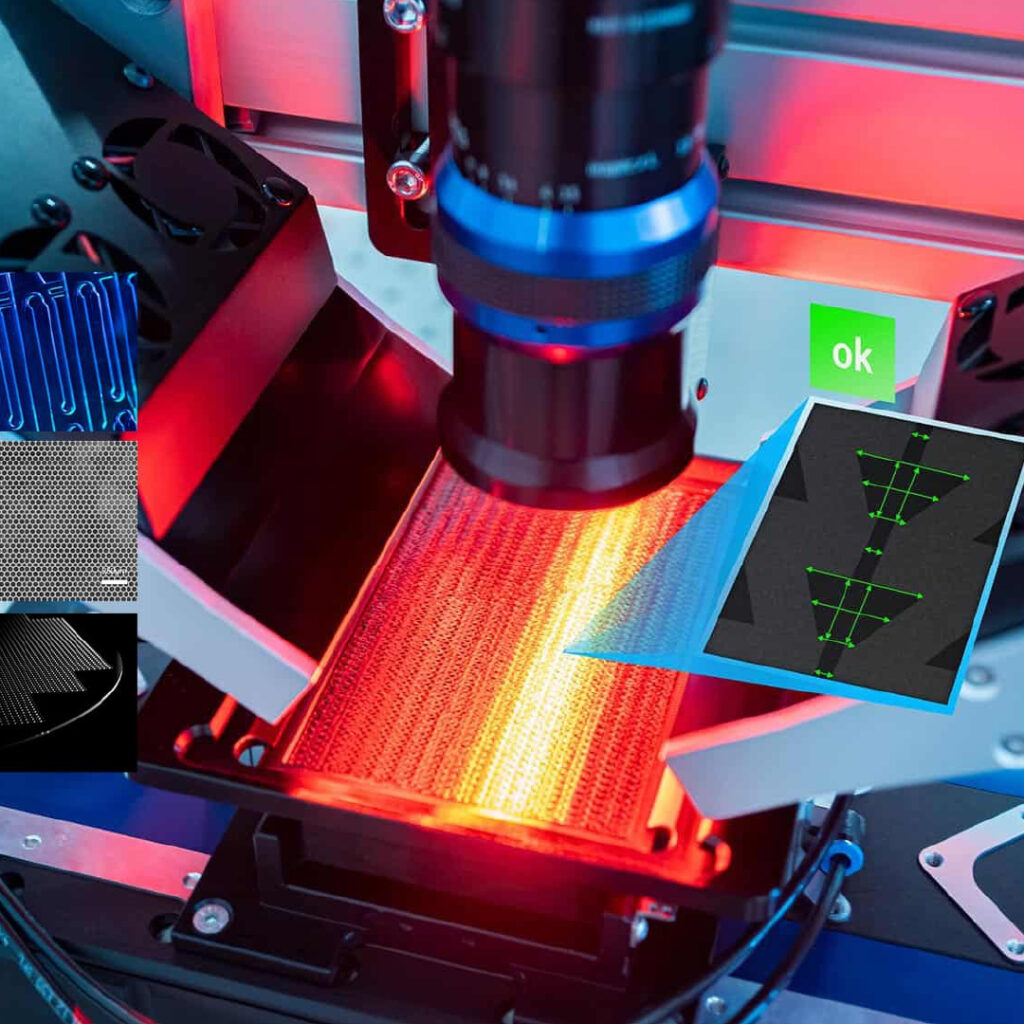

The miniaturization of microcomponents, sensors, actuators and sensor systems, micropumps, and injection-molded parts enables the production of highly integrated products in the smallest possible spaces. The resulting quality requirements place the highest demands on high-tech production processes to reliably detect common errors such as anomalies, defects, deformations, component placement issues, punctures, cracks, and burrs. Our machine vision solutions and inspection systems are specialized for inspecting miniaturized components and quickly identifying errors and defects. We utilize the latest optical technologies to achieve an optimal balance between speed, resolution, and efficiency

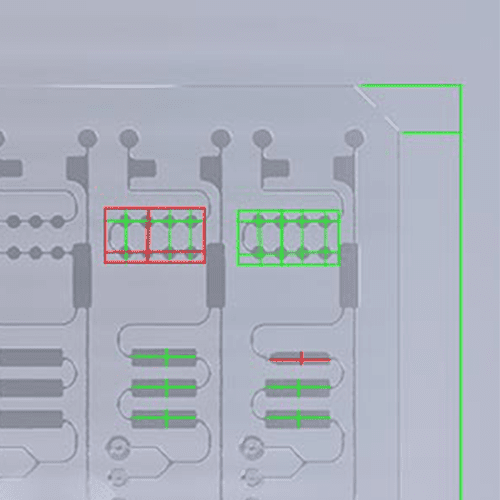

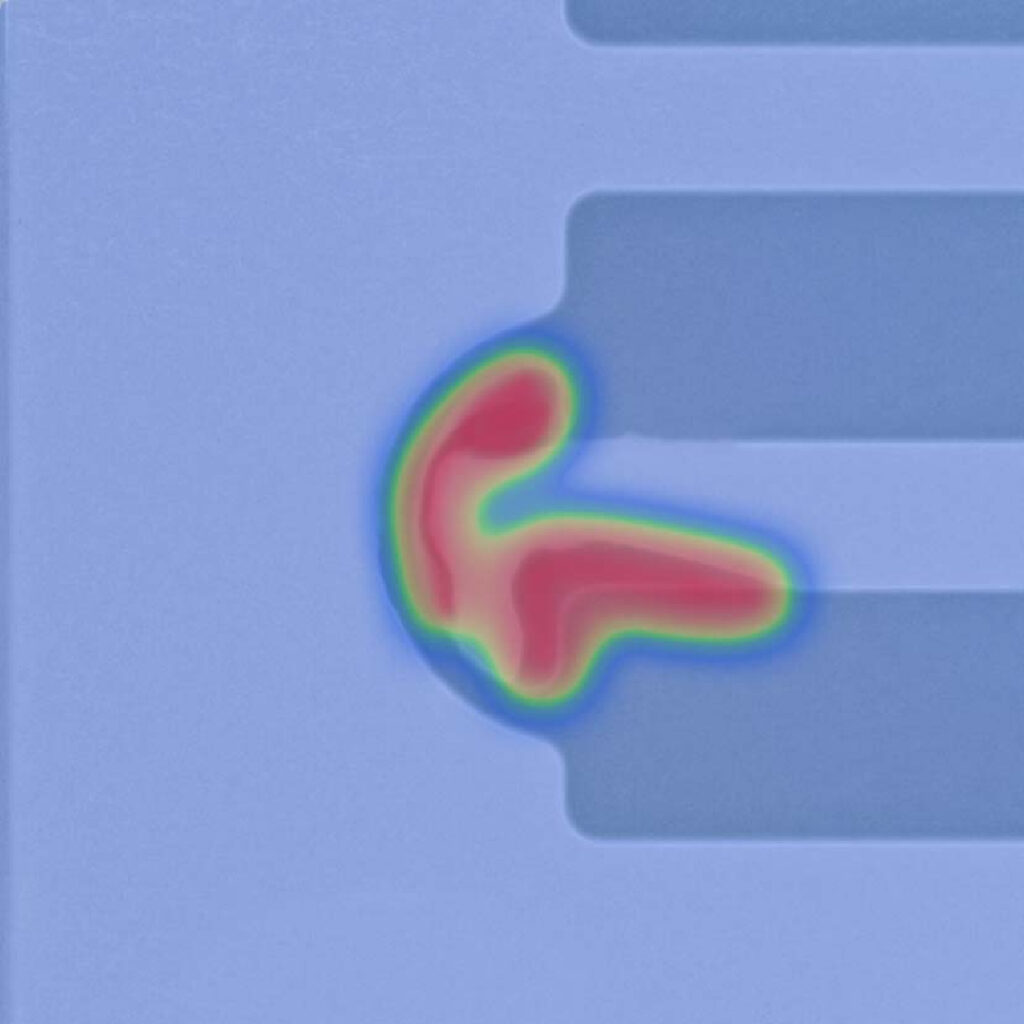

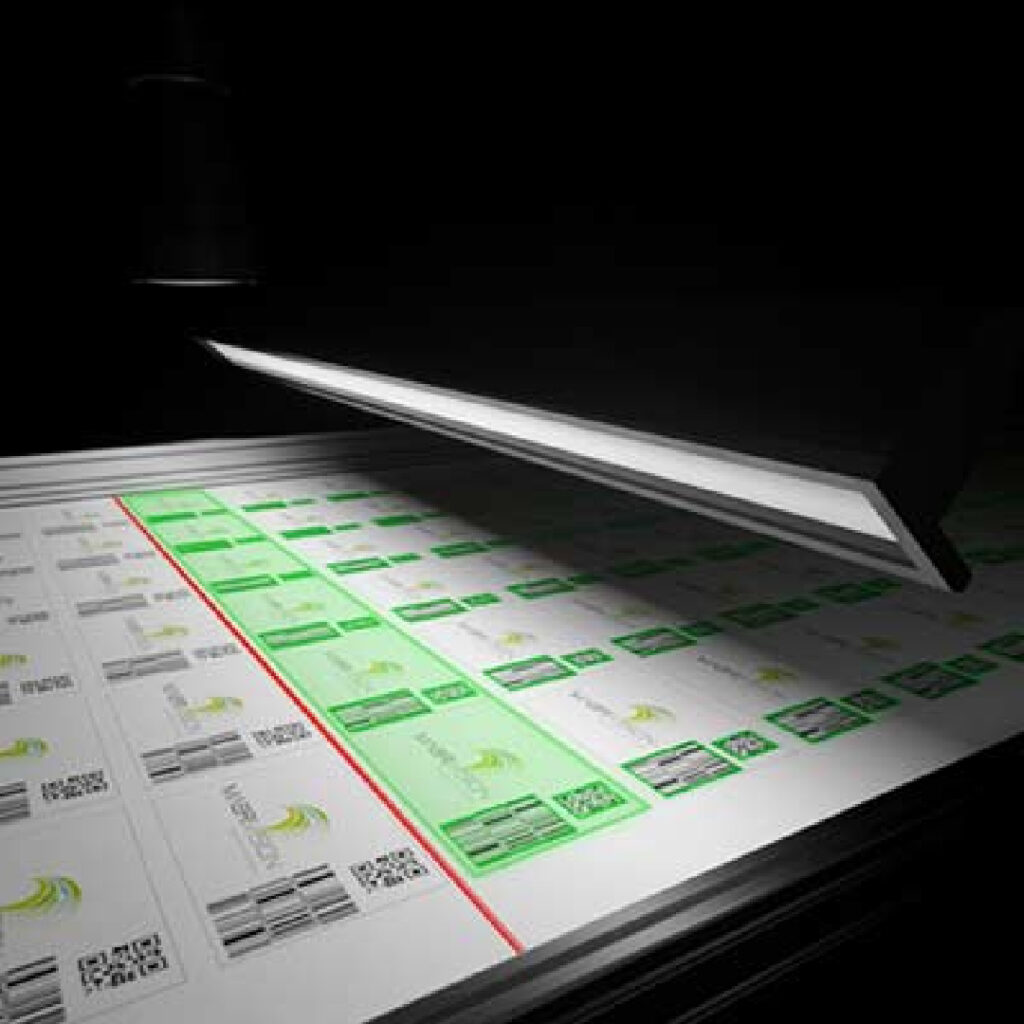

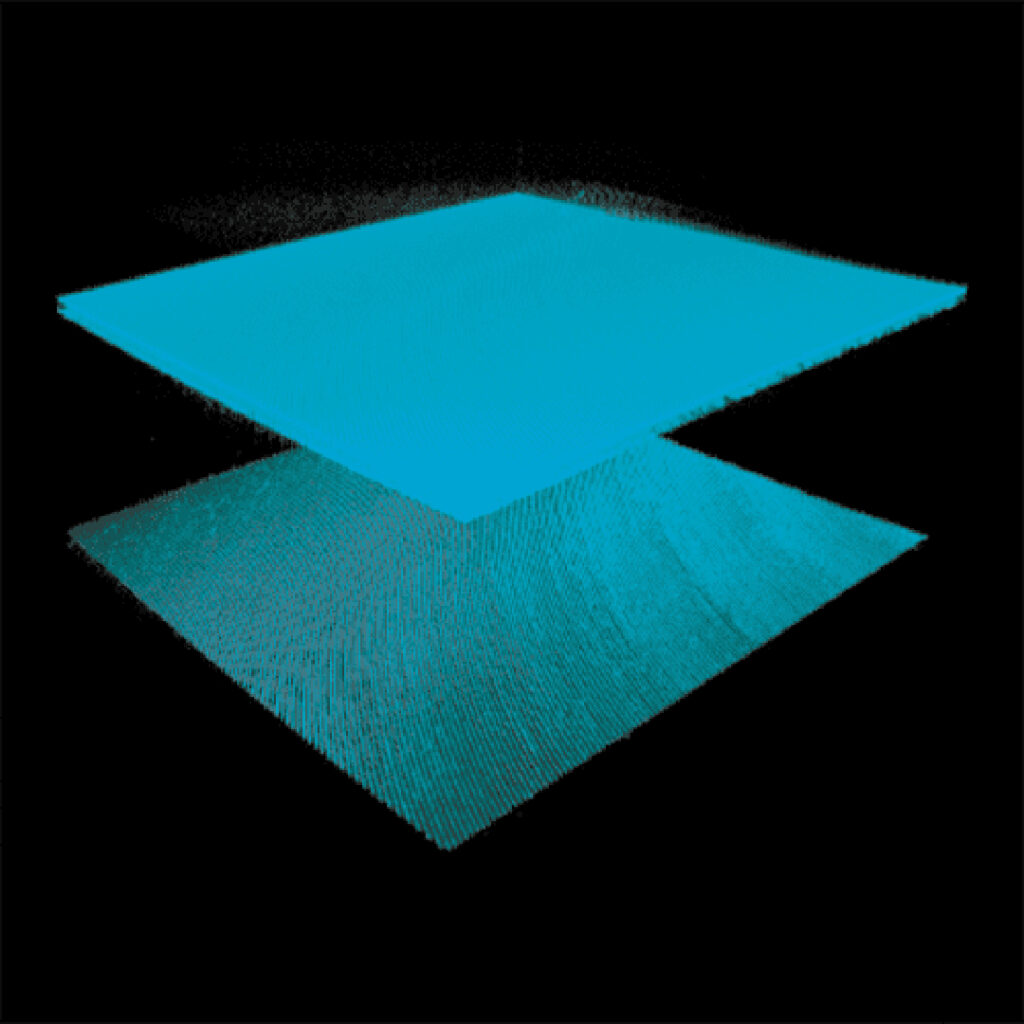

Our software platform is optimized for extremely high data throughput and enables the inspection of millions of features during the process. In addition to traditional inspection criteria, we utilize AI-supported algorithms to reliably detect anomalies in sensors, microfluidic systems, wafers, and other miniaturized components. Our OCT-based systems also allow us to generate optical cross-sectional images for measuring layer thickness. Our systems can be operated both stand-alone and inline within an automated production environment.

Laser microstructuring

Microstructuring and micromaterial processing with ultrashort pulse (USP) lasers is used in many industries. Our inspection systems are employed for rapid inline inspections of microstructure size in laser material processing.

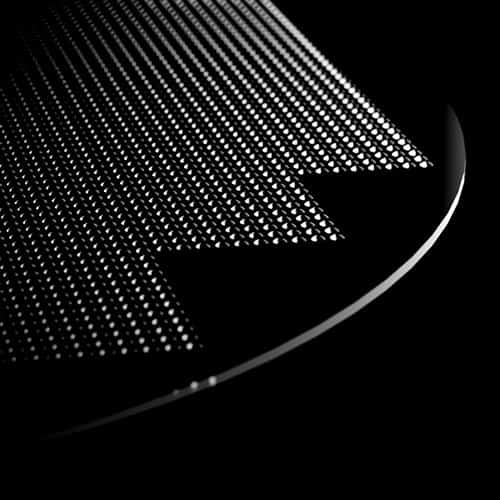

Wafer

Wafers can also be structured in 3D to enable the production of tools and miniaturized components. Our inspection systems measure the structure dimensions and detect anomalies.

Microfluidics

Our testing systems solve the challenges encountered in the large-scale production of microfluidic systems and lab-on-a-chip applications.

Micro 3D scans

We offer solutions for 2D/3D inspection of microarrays. Application areas include microlenses, stacks, sequencing, LOAC, fluidics, sensors, and medical instruments.

miniaturized sensors

The production of miniaturized sensors requires the measurement of features down to the micrometer level. Our testing systems and high-speed microscopes can capture these properties even under production conditions.

End-to-end turnkey solutions

We build turnkey testing systems for our customers. From the initial concept and all necessary qualification steps to ongoing service, we offer a complete solution from a single source. Together with our customers, we design efficient testing processes that integrate seamlessly into their production.

Software and hardware automation

Through collaboration with our partners, our team has gained experience in process and plant qualification. Our software offers essential modules necessary for qualification.

Precision and speed

We carefully design our systems according to the needs of our customers and their testing processes. Our goal is to achieve an optimal balance between precision and speed. To this end, we rely on parallelization and innovative technologies such as TDI, OCT, and AI.

Optical inspection systems for miniaturized components from MABRI.VISION

Dimensional accuracy

Machine Vision

Anomalies | Defects

Codes | OCR

layers

Testing solutions for miniaturized components

Discover our product portfolio

MV.CHECK Inspection Systems

Machine Vision: MABRI.VISION develops and builds machine vision inspection systems and solutions for your production processes.

Rotary indexer test systems

Our rotary indexing testing systems for quality assurance of your products are characterized by the combination of various technologies.

High-speed microscope - Automated testing

MABRI.VISION offers an inline-capable and cycle-time-neutral high-speed microscope for the automated inspection of microstructured components.

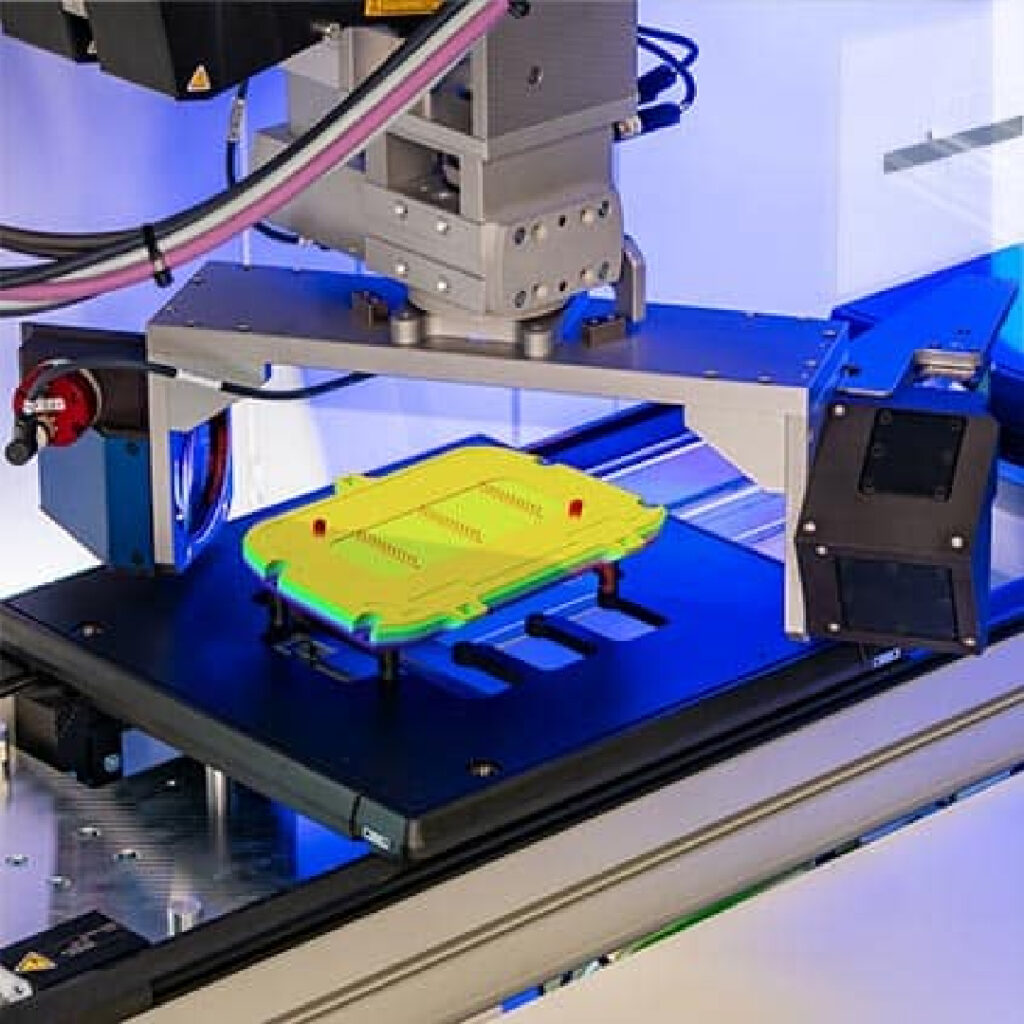

Inline 2D/3D measurement on the product carrier

We offer 2D/3D measurement on the workpiece carrier for your quality assurance with our MV.EYE i2 WT inspection system. Seamless and directly on the workpiece carrier.

Testing solutions for your miniaturized components

Interested?

We'll call you back!

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision