Embedded Vision Solutions

The demand for high-performance computer vision solutions is constantly increasing, even in application areas far removed from monitoring production processes. These new fields of application often place high demands on the scalability of such solutions. Examples include the retail sector as well as consumer goods such as automobiles, where high volumes are required at low prices.

Specifically, the requirements often include: low unit costs combined with minimal space, energy, and resource consumption. These increased requirements cannot be met with classic desktop-based systems and standard components

to achieve this. The solution lies in embedded systems equipped with a cost-effective and space-saving system-on-a-chip.

Using these miniaturized computers and special peripherals, it is possible to develop high-performance computer vision solutions with extremely advantageous space, cost and energy efficiency.

MABRI.VISION offers its customers support from the conception to the series production of such embedded systems. We utilize both classic image processing and deep learning, as well as our continuously growing expertise in low-level programming.

Our services at a glance

System design

We determine our customers' exact system requirements no later than after the project starts, but usually even earlier in various customer workshops. This is followed by a system design by our application developers. During this phase, the entire project is planned in detail and all essential components are defined.

Design of optics and lighting systems

Even in early development phases, we use simulation software such as Zemax for the planning, design and optimization of optical systems in order to develop customer-specific optics.

Embedded programming and image processing

For efficient design, we combine all components on our Linux platform and, above all, implement the core of each of our applications – image processing.

Deep Learning

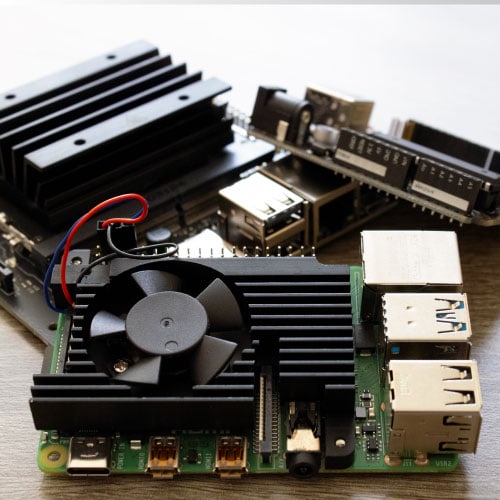

The NVIDIA Jetson platform provides a powerful tool for using complex deep learning applications in our embedded framework.

Embedded systems for QC applications from MABRI.VISION

Unrivaled power-to-weight ratio

Embedded systems deliver high performance in a small form factor and with low weight. They are therefore perfectly suited for applications in areas with limited design space, such as drones or sporting events.

Easy

scalability

Comparatively low manufacturing costs combined with minimal complexity ensure excellent scalability. This makes embedded systems very well suited for applications in the retail sector, for example.

Precision and speed

Despite their small size, feather-light weight, and cost advantages, embedded systems are ideally suited for industrial applications. We offer you and your customers maximum precision, availability, and speed.

Areas of application

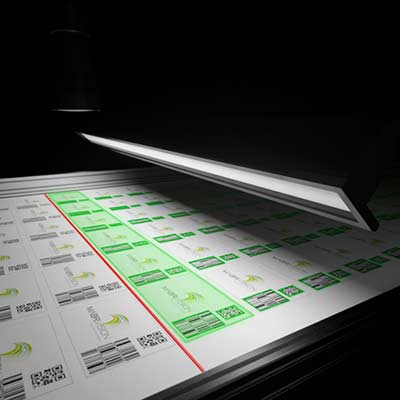

printing industry

Retail

Circular economy

agriculture

Medical technology

Example application - Accredited manufacturer of readout units in the DPG system

The DPG deposit system allows customers to easily and quickly return their deposit containers to the return stations, thereby promoting waste prevention and sustainability.

The latest requirements for counterfeit protection, speed, and reliability of reverse vending machines present significant challenges for machine manufacturers. MABRI.VISION is an accredited manufacturer of readout units within the DPG system. With our in-house developed multispectral LED modules, 360° readout unit, and perfectly coordinated software solutions, MABRI.VISION is part of the next generation of reverse vending machines.

Test solutions

Discover our product portfolio

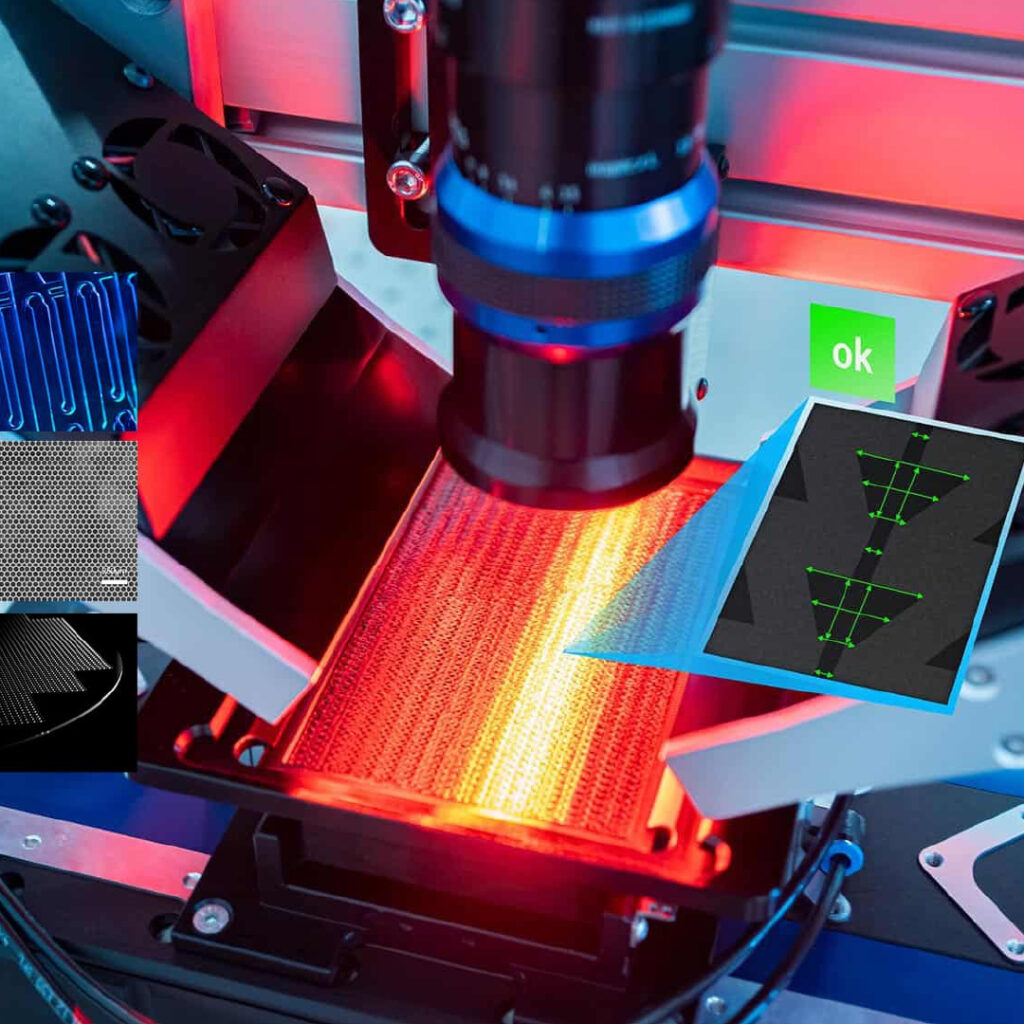

MV.CHECK Inspection Systems

Machine Vision: MABRI.VISION develops and builds machine vision inspection systems and solutions for your production processes.

Rotary indexer test systems

Our rotary indexing testing systems for quality assurance of your products are characterized by the combination of various technologies.

High-speed microscope - Automated testing

MABRI.VISION offers an inline-capable and cycle-time-neutral high-speed microscope for the automated inspection of microstructured components

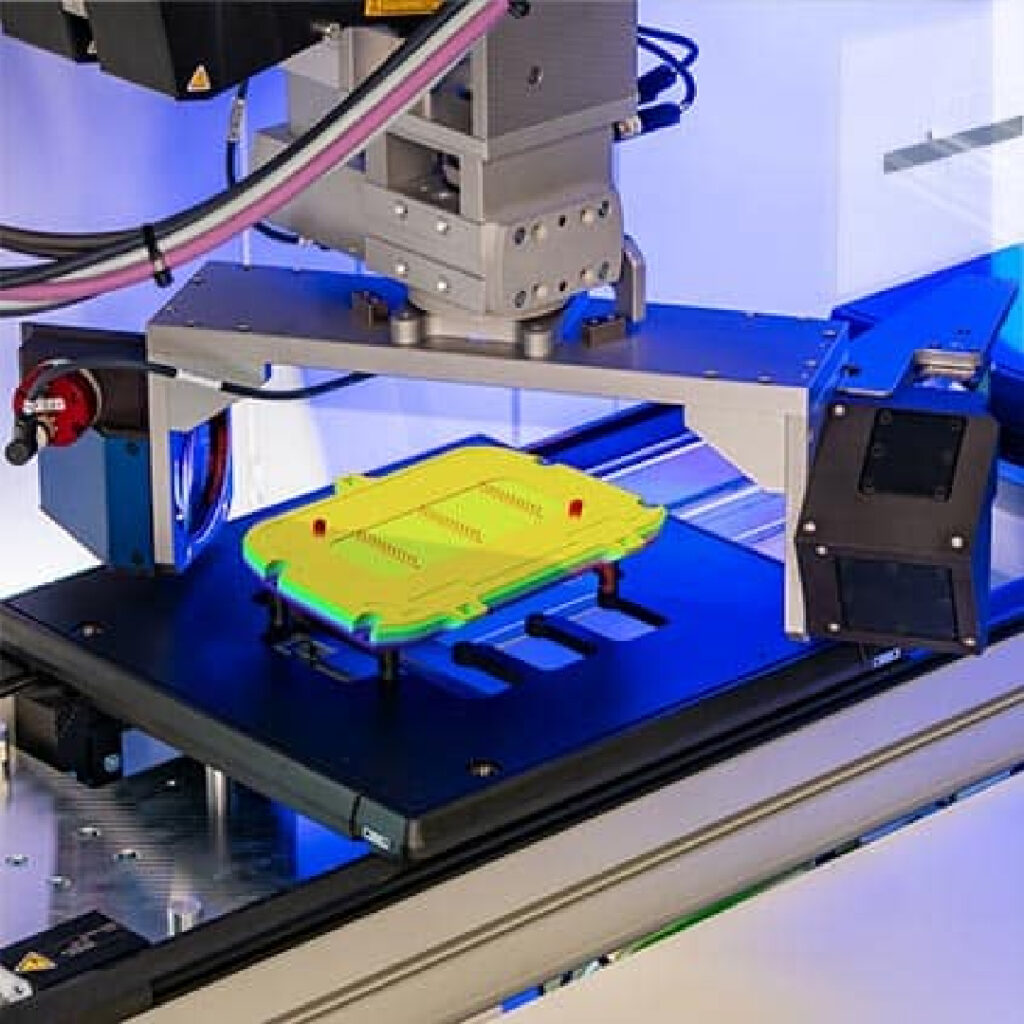

Inline 2D/3D measurement on the product carrier

We offer 2D/3D measurement on the workpiece carrier for your quality assurance with our MV.EYE i2 WT inspection system. Seamless and directly on the workpiece carrier.