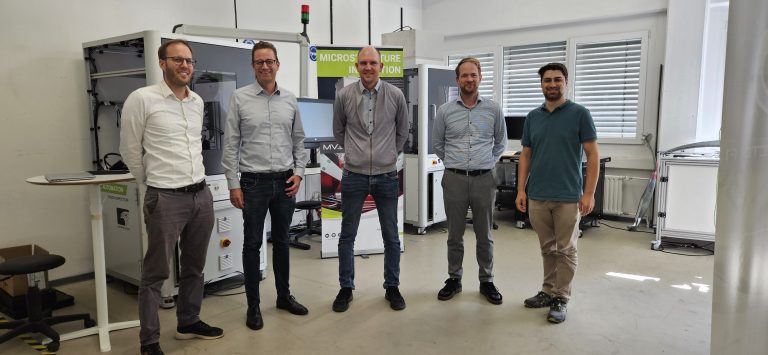

Visit from Denso

Visit from Denso: Last week we had a visit from our partner DENSO. It was an exciting exchange that once again demonstrated how valuable strong partnerships are for our joint development. With ROBOT.SPECTOR, we aim to systematically expand our robot platform – and for that, we need innovative partners like DENSO, who support us with their expertise and…