MV.EYE WT1

Testing the shape and wall thickness of plastic packaging

MV.EYE WT1

Testing the shape and wall thickness of plastic packaging

The MABRI.VISION MV.EYE WT1 inspection system enables reliable and rapid testing of the shape and wall thickness of semi-transparent plastic packaging. The inspection process is contactless and performed in sync with production cycles.

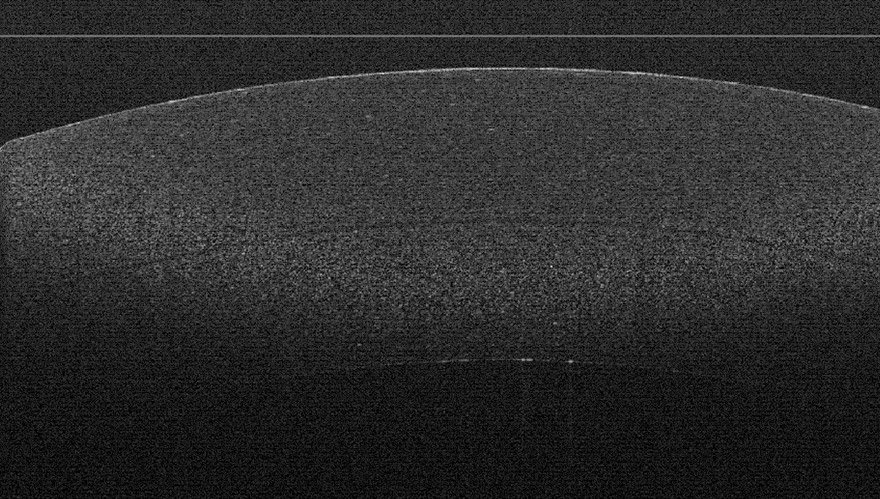

MABRI.VISION's OCT sensors are designed for industrial use and generate tomographic cross-sectional images of the objects being inspected. Our image processing enables rapid inspection of shape, wall thickness, and layer thickness. High measurement speeds of up to 240,000 Hz allow for seamless integration of the sensors into your production line, enabling efficient quality control.

Applications

- Testing of plastic bottles

- Inspection of blister packs

Exams

- wall thickness

- form

- Barrier layers

- Transit points

Industries

- Packaging

- pharmaceutical industry

- Slides

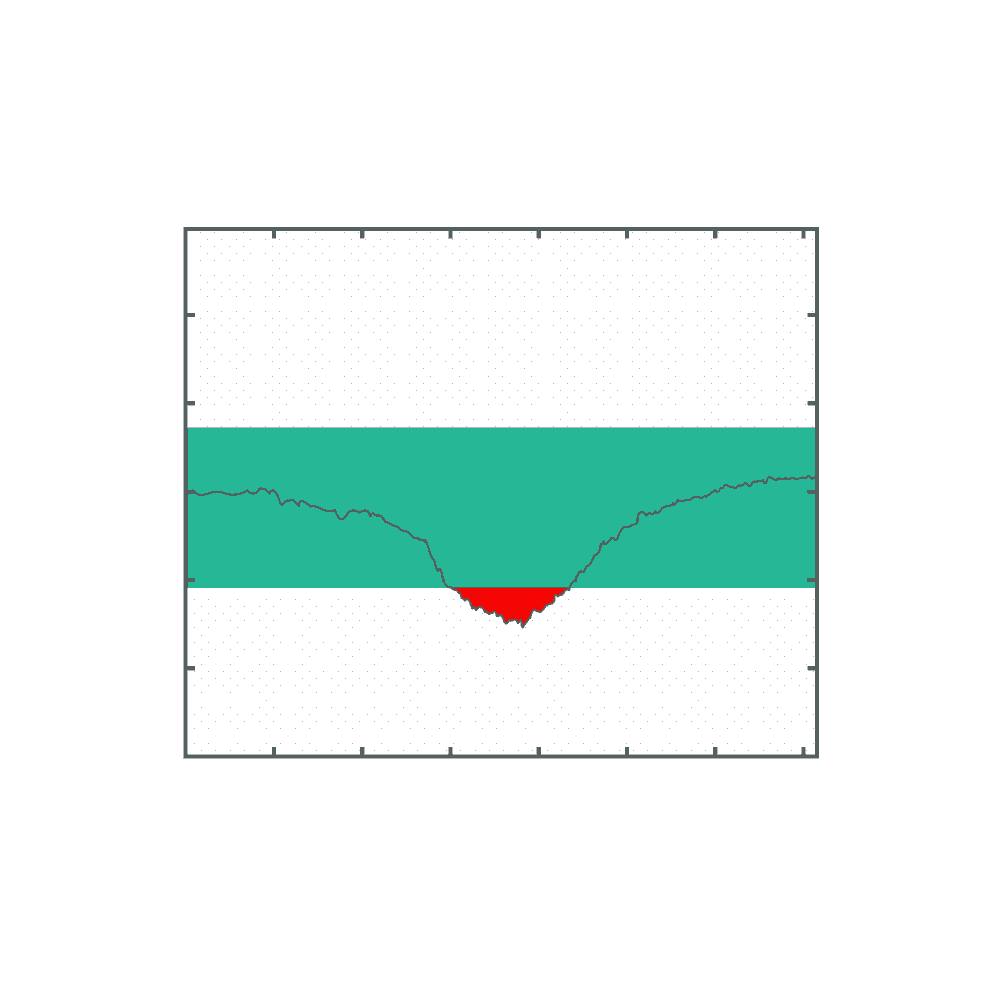

Wall thickness test

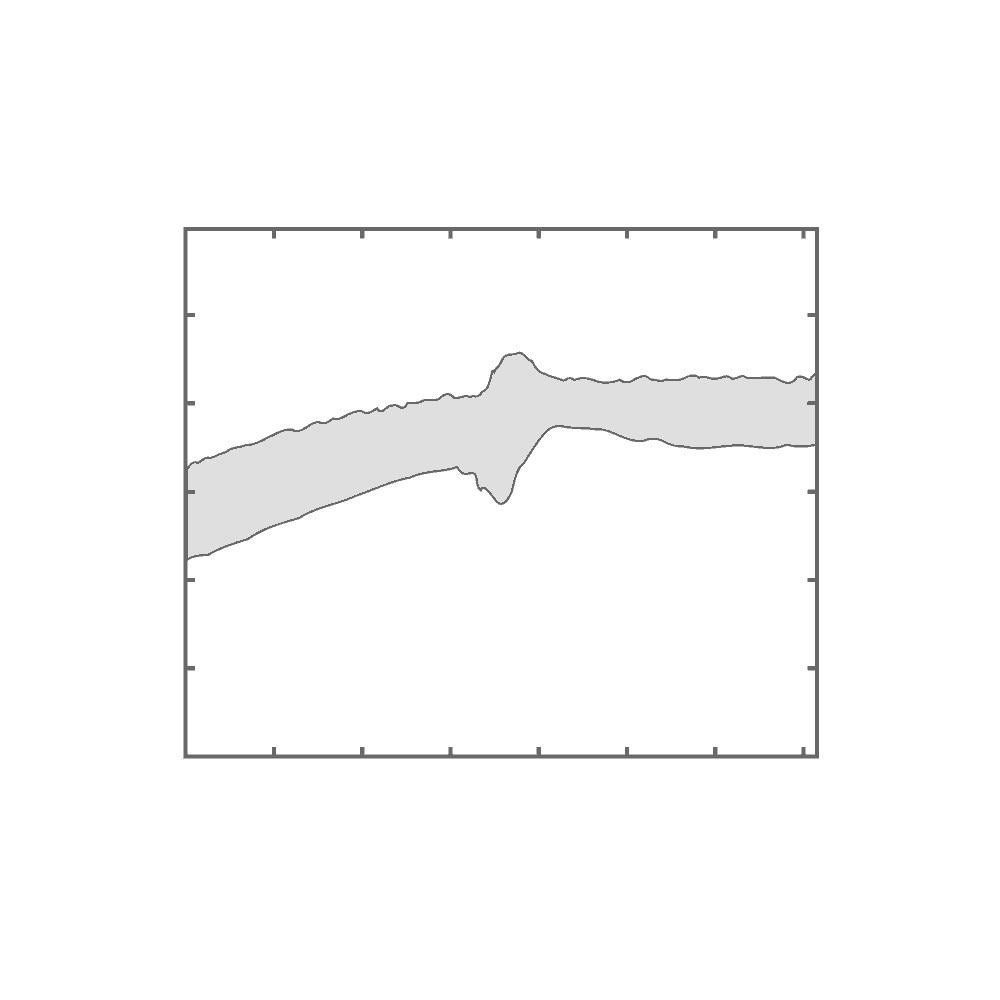

The MV.EYE WT1 testing system is characterized by its precise wall thickness testing capabilities. The test can be performed on all packaging made of semi-transparent plastics.

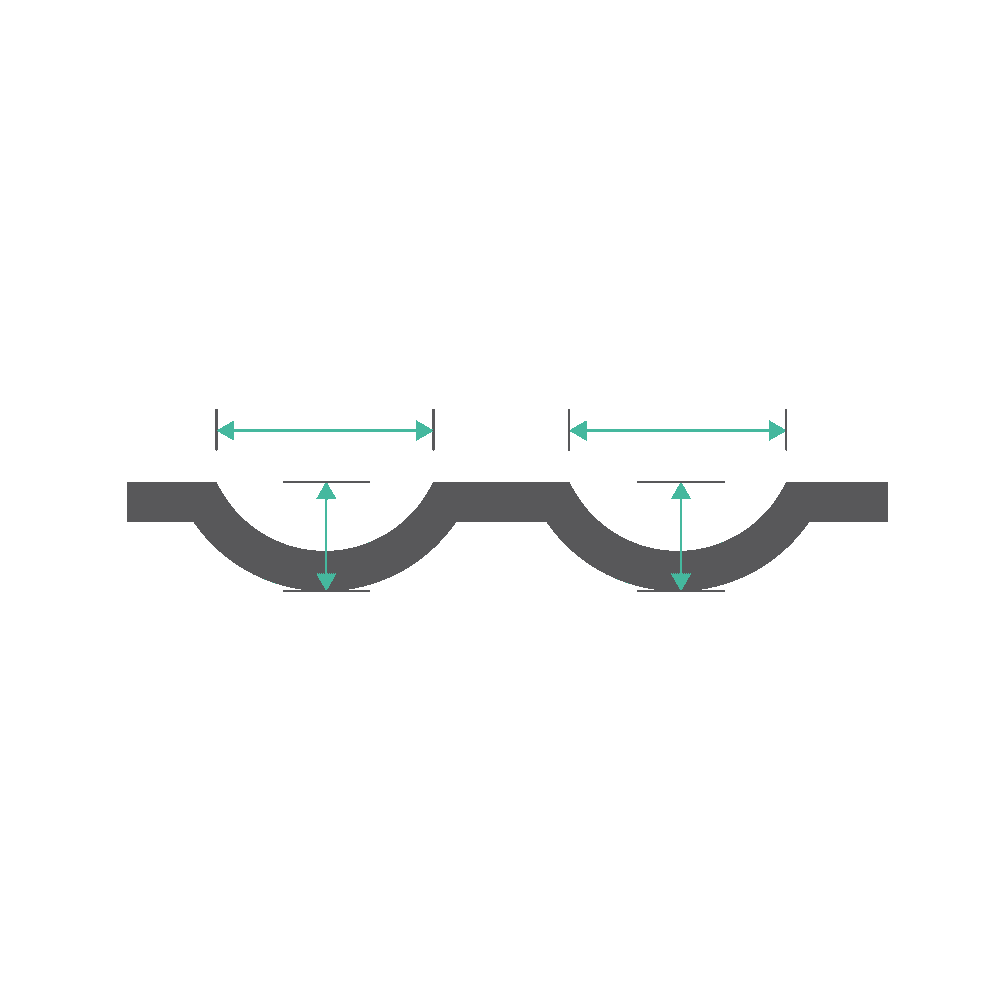

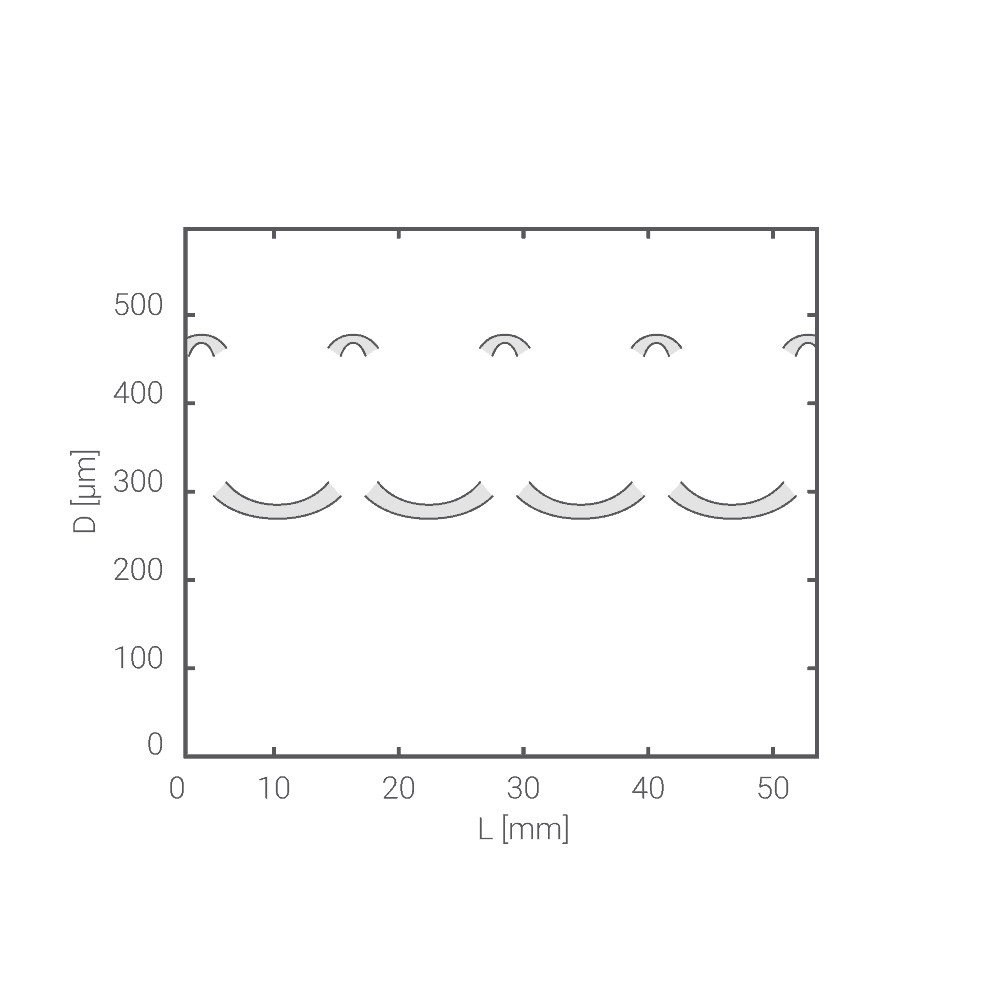

Form test

Cross-sectional images can be used in particular for checking the shape of films, such as blister packs. The width and height of fine structures can be precisely examined.

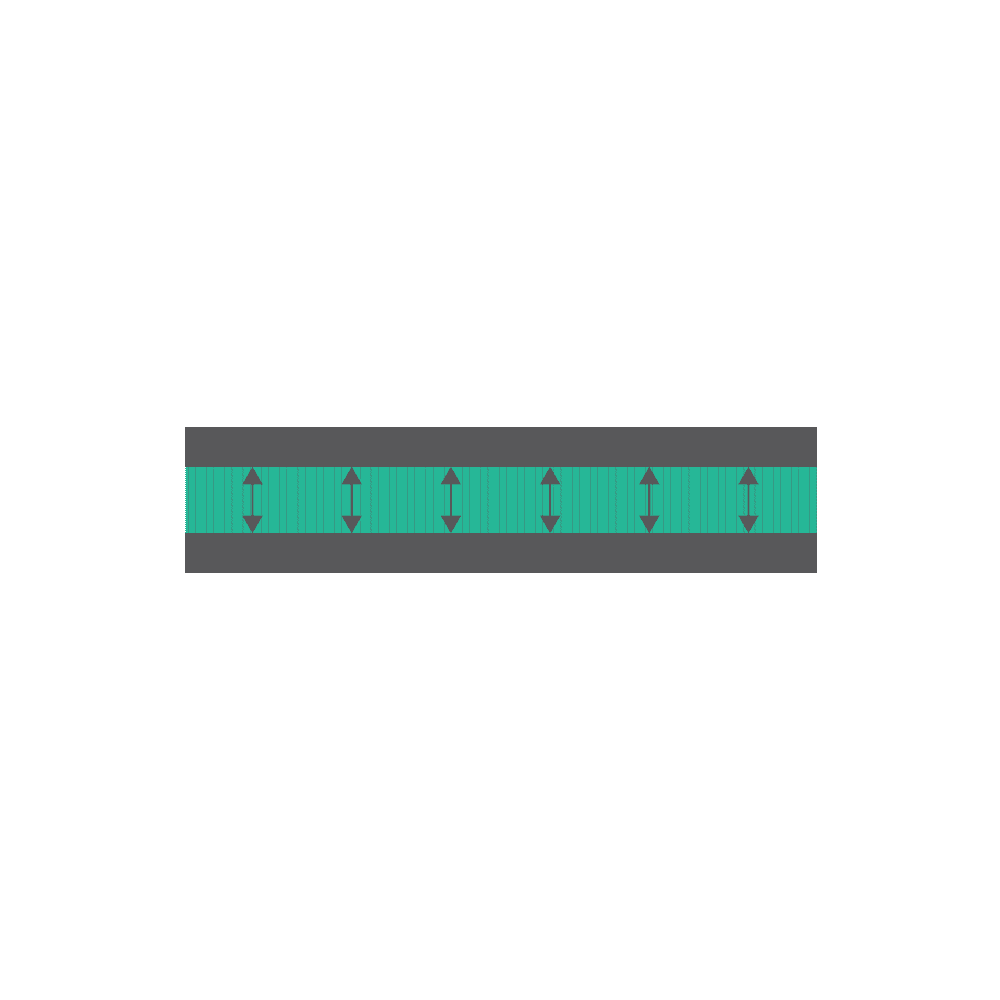

Testing of multi-shift operations

In layer systems with wall thicknesses from 10 µm, individual layers can be separated. By using sensors in the manufacturing process, tolerances of internal layers can be checked inline and non-destructively.

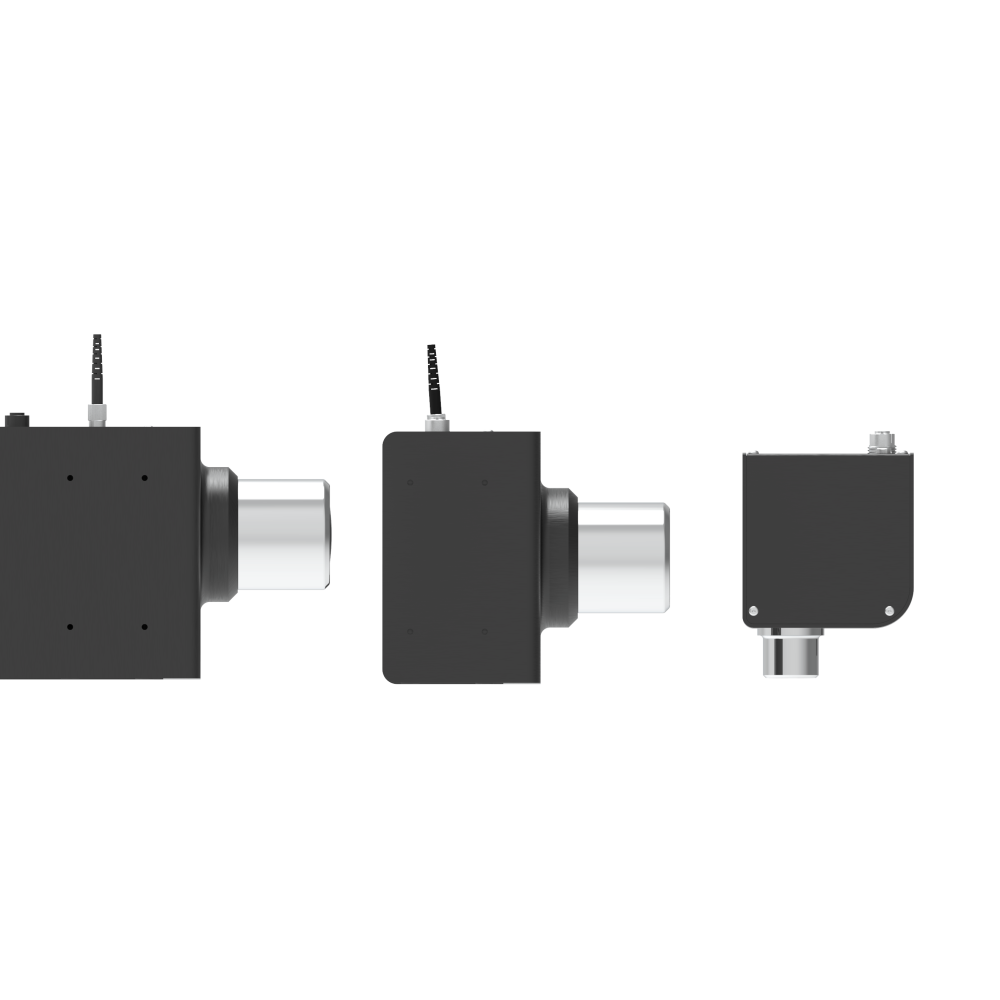

1D, 2D or 3D sensors

Depending on the application, we offer the right sensors. Measurements can be taken in 1D, 2D, and 3D. Our experts will design your testing system accordingly, ensuring you get the best solution for your needs.

contactless

MABRI.VISION sensors perform completely contactless testing. The purely optical method uses low-energy radiation and thus prevents, for example, the hardening of adhesive materials.

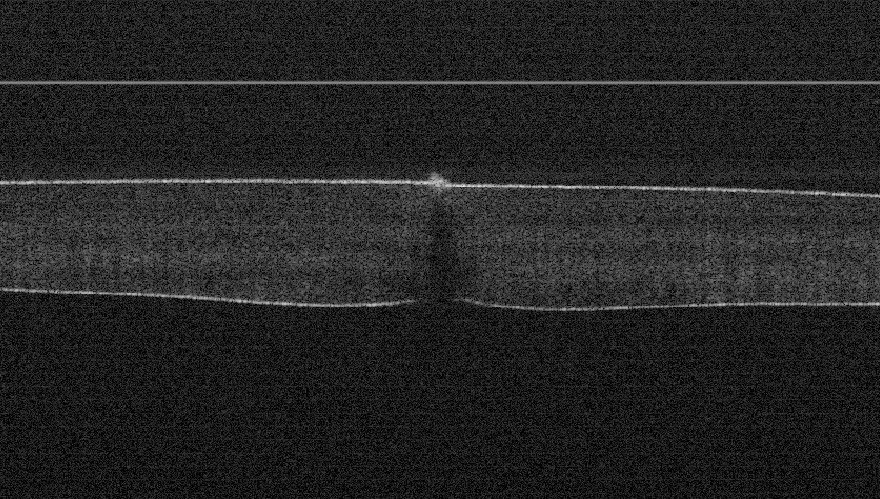

Examination of transition points

Quality defects such as visible seams or weak points on plastic packaging are reliably detected by the MV.EYE WT1 testing system. Analysis data enables you to adapt and improve your tools.

Universal: versatile in its applications

Blister

Deep-drawn packaging is used in the pharmaceutical industry – this can be fully tested with the MV.EYE WT1 testing system.

Bottles

The MABRI.VISION MV.EYE WT1 testing system is ideally suited for testing plastic bottles and provides data on shape, wall thickness and quality defects.

Slides

Rely on 100% quality control and ensure high-quality and defect-free products through the use of MABRI.VISION testing technology.

Example applications

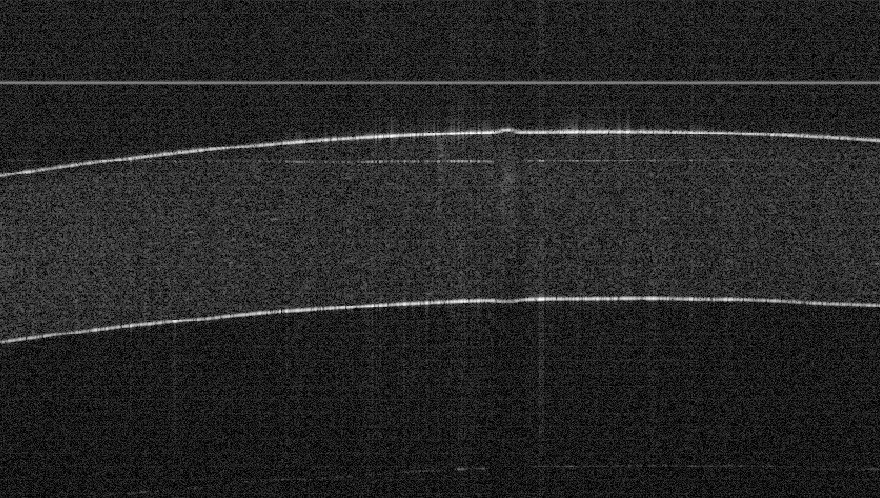

Wall thickness testing in extrusion blow molding

During extrusion blow molding, we inspect wall thickness and seam areas at critical points. This allows us to identify defects such as thin spots at an early stage of the process, which could later lead to cracking.

Wall thickness testing in injection stretch blow molding

In stretch blow molding of packaging, uniform material distribution and molding are crucial for subsequent functionality. MABRI.VISION sensors are used for wall thickness testing during the manufacturing process.

Wall thickness testing during deep drawing processes

In addition to wall thickness testing, MABRI.VISION sensors are also suitable for testing foil structures. Signal acquisition is performed using the same optics, thus avoiding shadowing effects that occur with conventional laser profile sensors.

Specifications

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision