Medical technology, pharmaceuticals, life sciences

Testing system for microfluidic chips

MICROSPECTOR MI1

Testing system for microfluidic chips

The MICRO.SPECTOR MI1 inspection system for microfluidic chips is an inline-capable vision solution for the automated 100% inspection of large-area and microstructured components. Fast, high-resolution image acquisition, combined with AI-supported evaluation software, enables reliable defect detection and verification of chip dimensional accuracy. The MICRO.SPECTOR MI1 inspection system can be operated stand-alone or fully automatically in cleanrooms.

Applications

- 100% inspection of chips

- Detection and sorting of defective chips

- Quality assurance

Areas of application

- Production of IVD chips

- PCR chips

- Microfluidics, Lab on a Chip

- Arrays

Industries

- Medical technology

- Pharma

- Life Sciences

What are we testing?

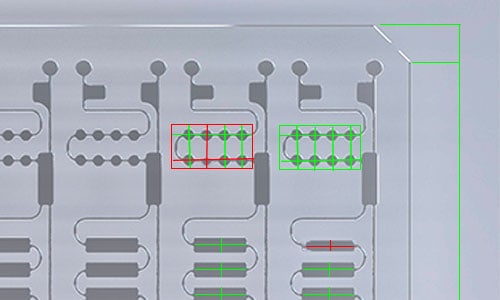

Especially in the production of the finest structures, a wide variety of process-related errors can occur. The MICRO.SPECTOR MI1 inspection system enables 100% inspection of microfluidic chips and detects even the smallest defects and shape deviations. The system can be used for end-of-line inspection or directly in the manufacturing process of components.

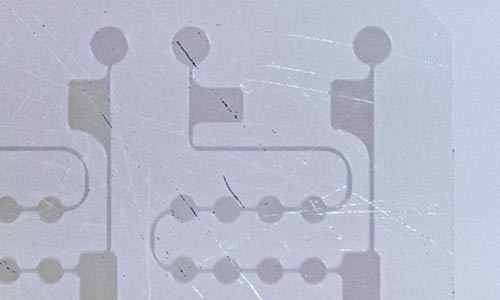

Scratches & Fibers

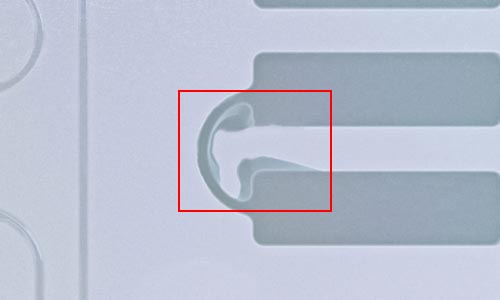

Webbed feet & faulty injection

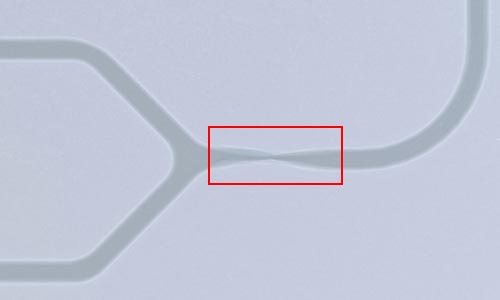

Thin spots & closures

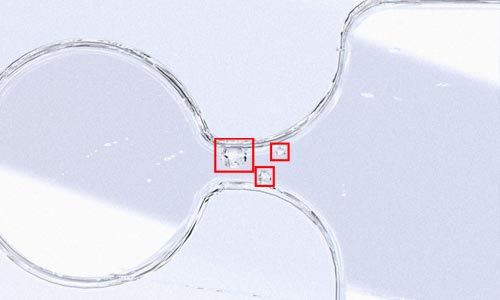

Particles & Inclusions

Dimensional accuracy & tolerances

Advantages and special features

100% inspection in line with production cycle

Testing of all features using a test system

Interface to your ERP and production system

Flexibly adaptable to your application

Manual loading, robot loading & product carriers

Suitable for cleanroom use

Databases, reports & statistics modules

Best in class high-speed machine vision system

AI-supported evaluation of defective cash registers

Applications and implementations

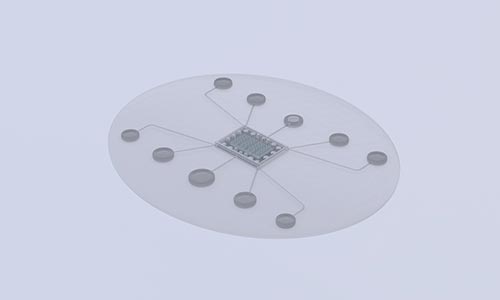

Transparent chips

Transparent chips offer the advantage that many tests can be performed using transmitted light or dark-field illumination. Manufacturing-related defects often occur in the layer structure during channel closure, which we reliably detect with our vision system.

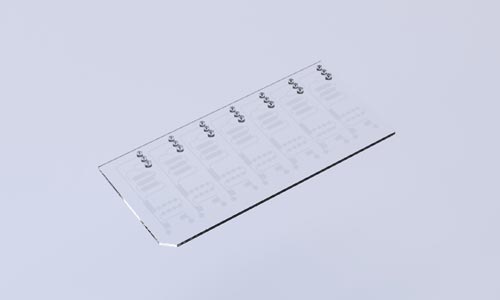

MTP format microstructures, black

Large-format chips represent the next class of microfluidic systems. Through the miniaturization of the arrays, the MICRO.SPECTOR MI1 inspection system captures and processes more than 1 million features and structures per MTP.

3D microstructures

software

Modular

MABRI.VISION software is designed modularly. In addition to a wide range of standard components, we are happy to extend the software with suitable modules for your application. All common interfaces are available for seamless integration into your production process.

Databases

The MV.IMAGING software supports your quality assurance through the use of databases for production orders and recipes. The database interface is tailored to the specific requirements of your tests and evaluations. All data can be exported as structured test reports in .csv, .xls, or .pdf format.

Statistics / Analysis

Our software platform offers a wide range of visualization options. Meaningful statistics help you maintain an overview of production processes and quality assurance. Our software experts are familiar with the specific requirements of various industries and design the software with insightful key performance indicators and useful tools such as good part counters, error and measurement image storage, and early warning limits for process support.