Testing solutions for steel and plastic pipes

As a leading provider of industrial image processing solutions, MABRI.VISION delivers high-precision inspection systems for the quality control of steel, stainless steel, and plastic pipes. With our customized solutions for automated pipe and tube product manufacturing, we guarantee 100% inspection for dimensional accuracy and defects.

Our advanced pipe testing systems cover all key quality control points – from precise inspection of the end face, inner and outer chamfers, to thorough examination of the surface and weld seam. Furthermore, we offer testing solutions for pipe inner diameters along the entire pipe length.

Trust MABRI.VISION for seamless quality control in your pipe production. Our testing systems for steel and stainless steel pipes minimize production errors and ensure consistently high quality for your pipe products.

Experience how our machine vision inspection systems optimize the efficiency and quality of your manufacturing processes. With MABRI.VISION, you invest in the highest quality and precision for your pipe production.

Testing solutions for steel and stainless steel pipes

Efficiency and precision

Our systems are designed to handle high belt speeds and low cycle times.

Tailor-made solutions

We develop customized applications and process controls that integrate seamlessly into your existing ERP and production systems.

Extensive testing options

We offer monitoring of the welding process, testing in the sawing center and in the drawing process, as well as various surface, scoring and weld seam inspections.

Comprehensive data management

Comprehensive data storage, measurement reports, and documentation images. This provides you with detailed insights into the testing process and valuable information for your quality assurance.

Your success is our goal

We are pleased to present our innovative solutions for the optical quality inspection of pipes. Our goal is to support you in maximizing the quality of your products.

End-to-End

From test design on initial samples to full automation – we offer turnkey solutions

Where do we test?

From the welding process to the finished pipe

What are we testing?

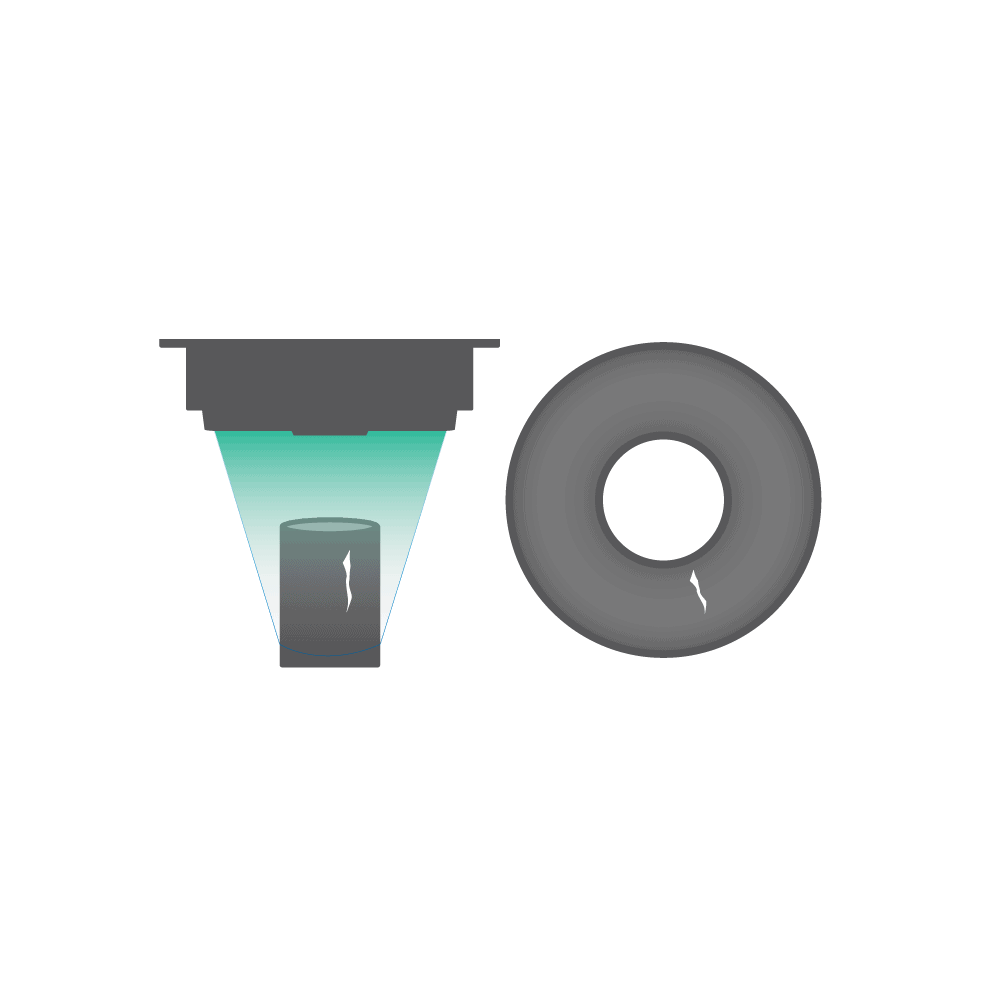

Internal chip testing

The high-speed focusing system developed by MABRI.VISION generates internal images on different image planes and enables reliable internal chip inspection

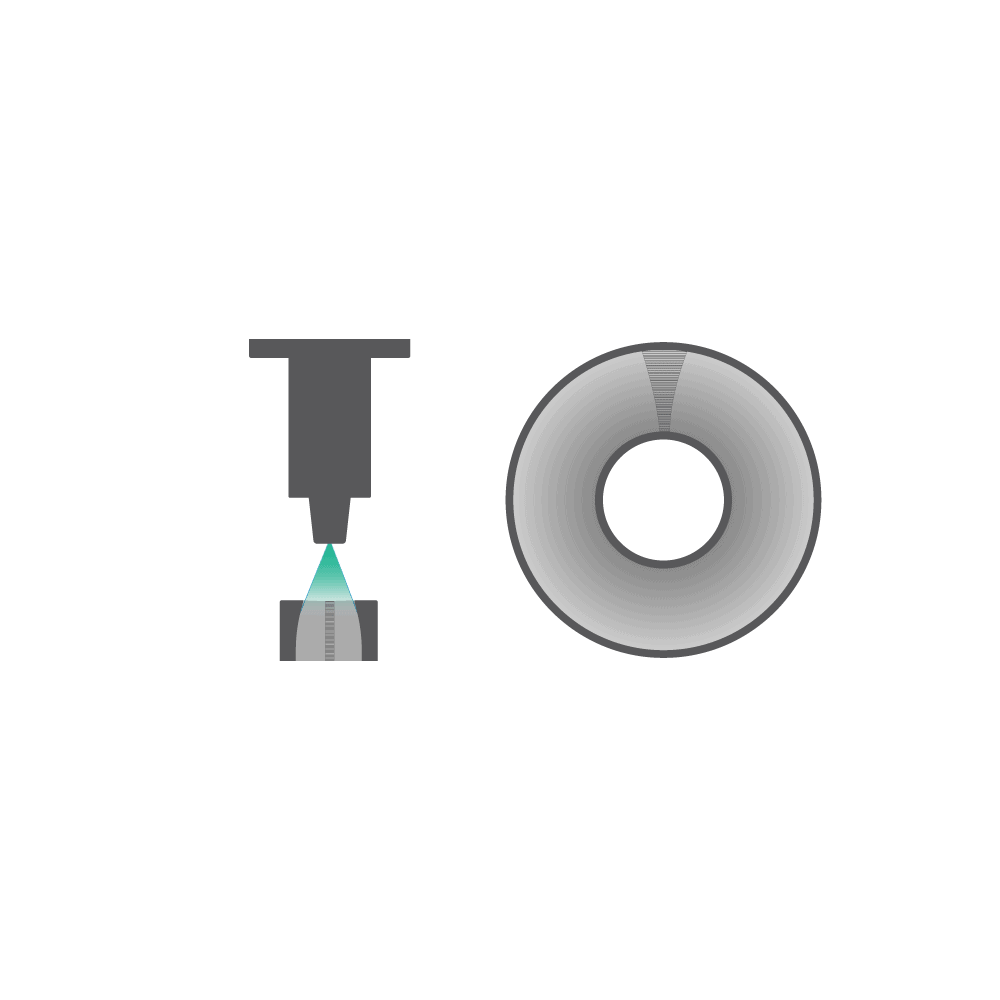

Inner & outer chamfer

Our testing system records the exact dimensions of metal tube end faces and checks both the inner and outer chamfer for presence, shape and tolerances.

360° - lateral surface

Our testing systems guarantee uncompromising testing of the outer surface of metal pipes in 360° – for optimal further processing.

360° - Inner surface

The inspection system is specifically designed for testing metal pipes through the use of multiple optics and offers, among other things, a 360° inspection of the inner surface.

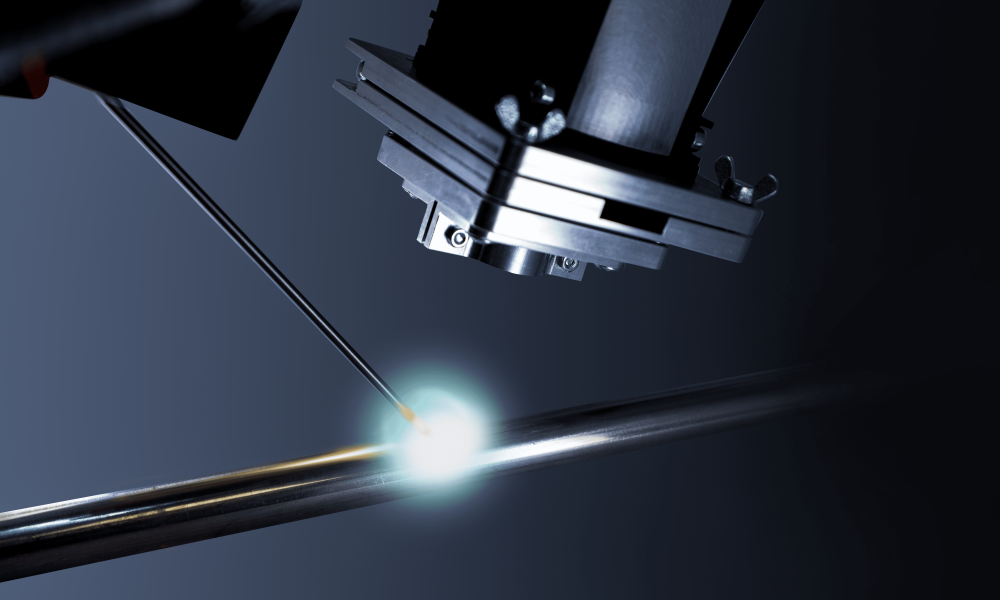

weld inspection

Optical sensor technology enables non-contact testing of welds for defects and compliance with tolerances.

Diameter & Ovality

The use of the MABRI.VISION high-speed focus system allows for high-speed testing of metal tubes, enabling integration into your production processes.

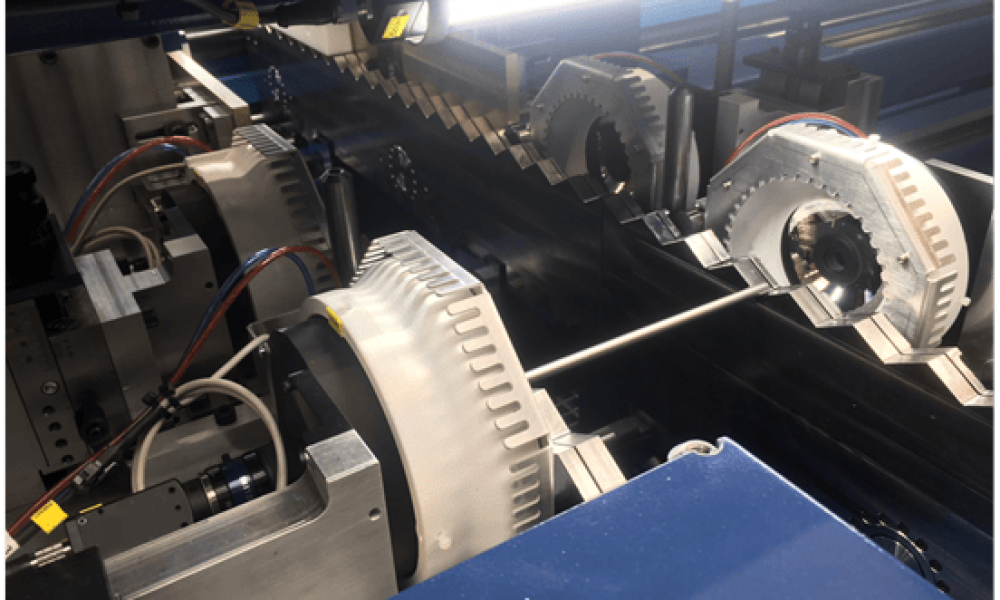

Welding process

Detection of electrode and gap in the welding process (TIG welding).

Groove test

Detection of scratches, nicks, grooves, draw marks & other defects.

Surface inspection

Detection of surface defects using our in-house AI platform DEEP.MV.

INSIGHTS

The right solutions for your production

Testing the pipe quality after sawing

In a rapid double cycle of just 2.3 seconds, the system efficiently checks the inner and outer chamfer, ovality, diameter, and internal stress of the pipes. It also detects defects on the pipe surface. The high flexibility of the testing system allows for the inspection of pipes with varying diameters and lengths, thus ensuring comprehensive and reliable quality control after the sawing process.

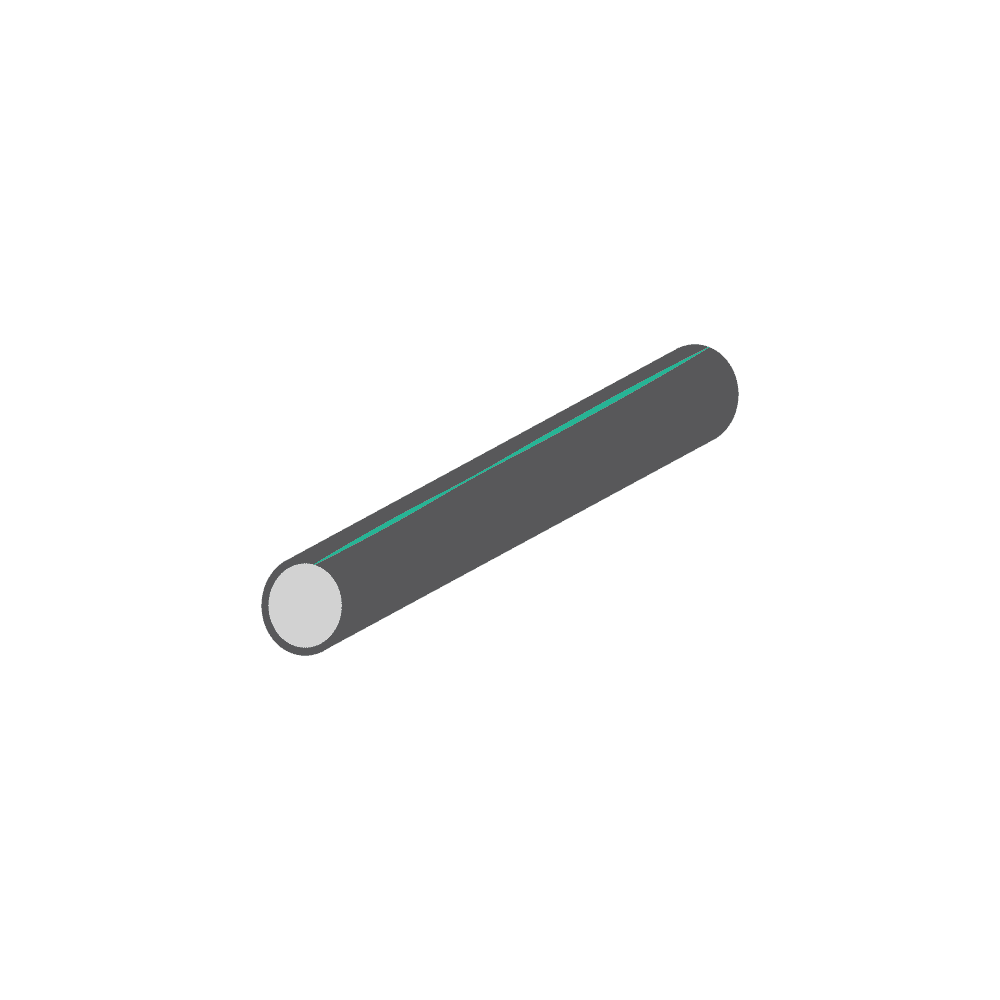

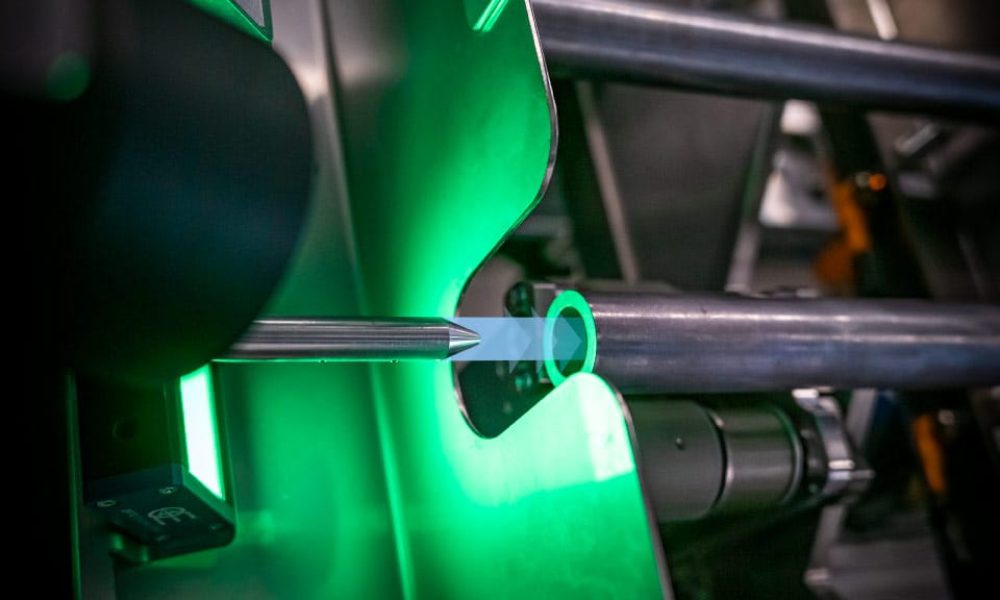

Testing pipe inner diameter

Using an innovative process, we ensure precise testing of the pipe's inner diameter. This involves employing a high-precision optical sensor mounted on a lance that enters the rotating pipe. This advanced technology allows us to perform extremely accurate measurements and guarantee continuous quality control. This testing process is particularly important for pipes with variable diameters, ensuring consistent adherence to specifications and standards in pipe production.

Welding process monitoring

Our welding process monitoring system is an efficient machine vision solution that can be directly integrated into the welding process. By using state-of-the-art image processing technology, we are able to monitor the welding process in real time to ensure quality, precision, and safety.

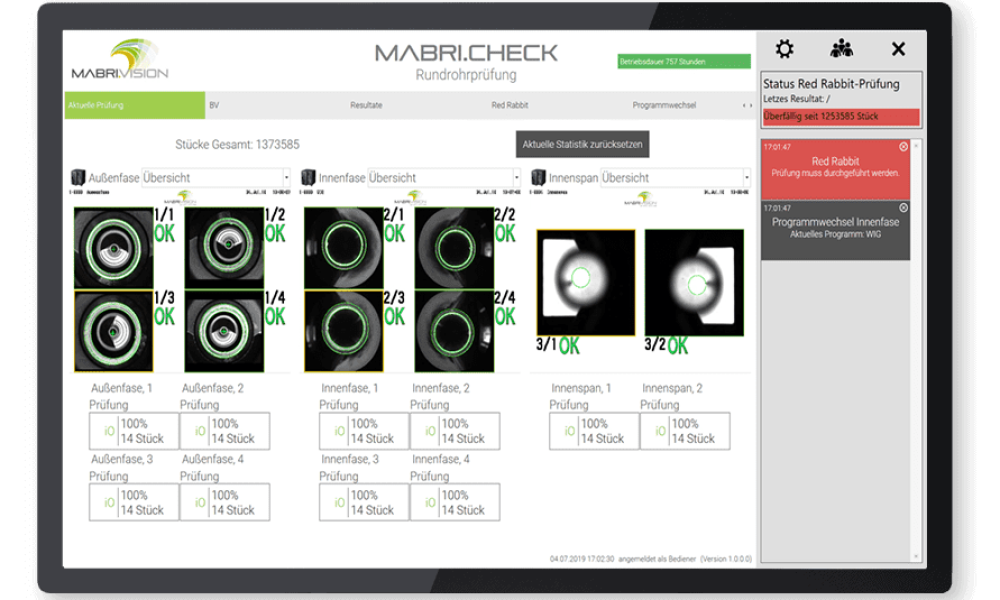

Our software solutions

Our advanced testing software provides comprehensive solutions for data acquisition, analysis, and results presentation. It covers a wide range of functions, from user management and database systems to the visual representation of key performance indicators and tolerances. With our software, we offer user-friendly, clearly structured solutions that enable you to efficiently manage your testing data and gain comprehensive insights into your test results. With MABRI.VISION, you have control over your quality data and can ensure that your production always meets the highest standards.

FAQs about pipe testing

How quickly does MABRI.VISION conduct testing?

It depends entirely on your application and your product. We have implemented tests that can perform a complete inspection of pipes within a few seconds. To further increase throughput, we can also build parallel testing stations for a dual-cycle process.

What systems does MABRI.VISION offer for pipe testing?

We develop testing solutions for our customers that can be directly integrated into the production line. Because on-site conditions vary considerably, we specialize in building our testing systems from a modular system. This allows us to optimally address our customers' needs.

What resolution does MABRI.VISION use for inspection?

We can build very high-resolution testing systems for pipe inspection. The challenge lies in finding the optimal balance between time, resolution, and effort. We typically detect defects as small as 0.1 mm. However, we have also implemented tests that can detect even the smallest scratches in the micrometer range.

Can I configure my exam on the system myself?

We are working on creating a platform where our customers can implement virtually any type of test. Currently, the systems are designed so that the tests are implemented by our experts and thoroughly tested for functionality. This allows us to guarantee the performance of the QC.

Does MABRI.VISION also offer turnkey testing systems?

The answer is: yes! We see ourselves as a provider of turnkey testing systems, which we offer our customers as an end-to-end solution, from the initial inquiry to on-site integration and commissioning.