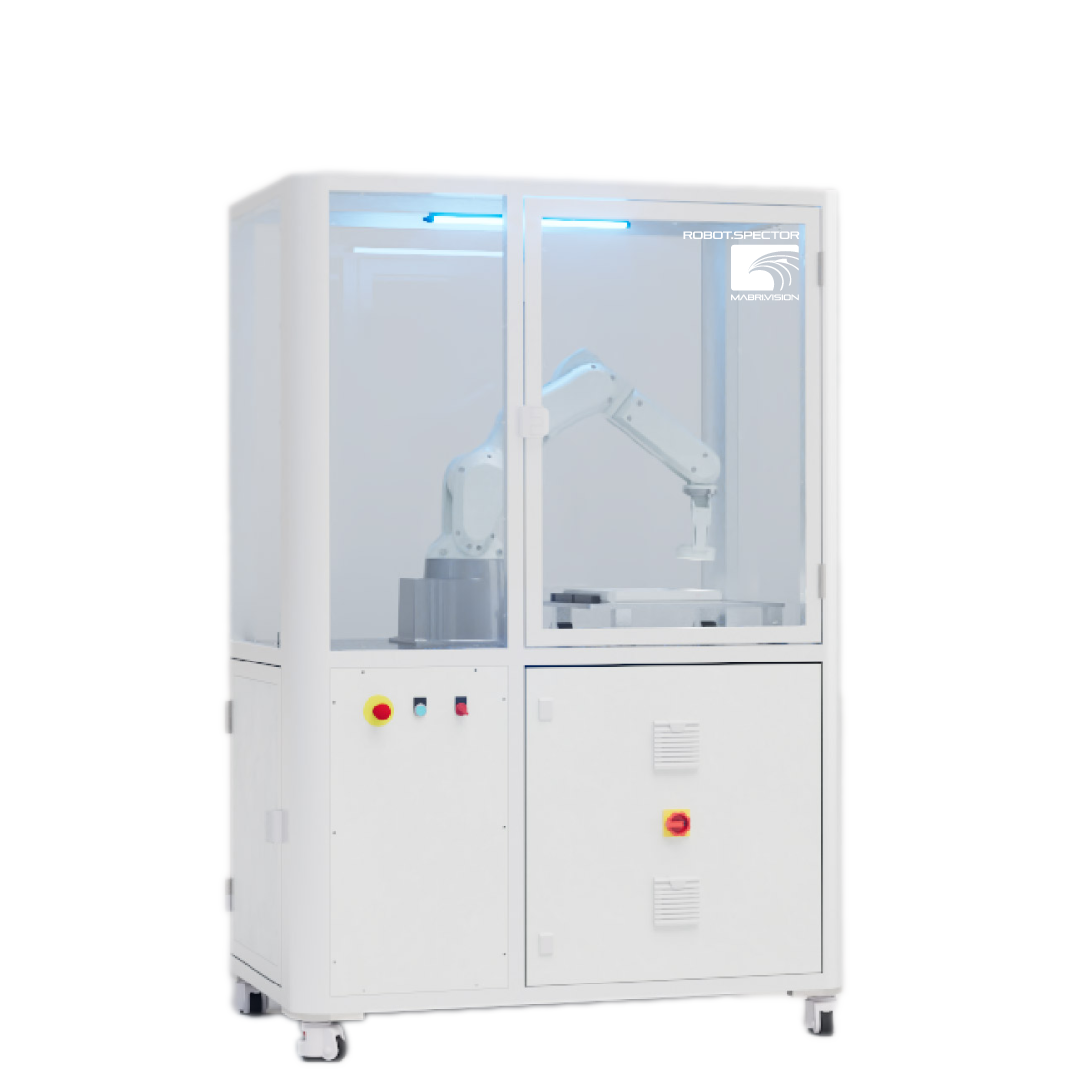

ROBOT.SPECTOR: Precise quality control with a flexible robotic test cell

Tailor-made testing procedures, high-precision measuring technologies and fully integrated data processing for your quality assurance

Key advantages at a glance

With ROBOT.SPECTOR, you're choosing a test cell that reduces costs, ensures quality, and integrates seamlessly into your production. Three reasons why our customers choose us:

Automation saves you costs

Reduce testing effort and personnel costs – with automated processes that can be scaled and adapted.

Precision through high-end sensor technology

State-of-the-art 2D/3D sensor technology enables micrometer-precise, reproducible testing – ideal for demanding quality requirements.

Everything from a single source

Robots, sensors, software and integration – we deliver the complete solution, ready for use and tailored to your process.

Put an end to quality control bottlenecks in your production

Quality control of complex products presents many companies with significant challenges. Manual inspections are time-consuming, prone to errors, and create production bottlenecks. ROBOT.SPECTOR offers the solution to these problems.

Conventional quality control

- Time-consuming manual inspections cause production bottlenecks

- Inconsistent results due to fatigue and subjective assessment

- Areas that are difficult to access remain unchecked

- High reject rates and costly rework

- Extensive adjustments required when products change

- Limited documentation and traceability

- Difficult to scale due to staff shortages

With ROBOT.SPECTOR

- Up to 70% faster test cycles with higher precision

- Consistent results around the clock without fatigue

- 360° inspection also covers hard-to-reach areas

- Reduction of the reject rate by an average of 35%

- Complete documentation and full traceability

- Seamless integration into your material flow in production

ROBOT.SPECTOR variants – tailored to your component

Our inspection cells are modular and can be flexibly adapted to your requirements. Depending on space requirements, cycle time, and component size, we use compact or high-performance robots from DENSO, Mecademic, or Epson – combined with the appropriate sensors and software for your application.

ROBOT.SPECTOR S

- Arm reach: 260 mm

- Payload: 0.5 kg

- Repeatability: ±0.005 mm

- Maximum object size: 50 x 50 x 25 mm3

ROBOT.SPECTOR M

- Arm reach: 505 mm

- Payload: 4 kg

- Repeatability: ±0.02 mm

- Maximum object size: 250 x 250 x 120 mm3

ROBOT.SPECTOR L

- Arm reach: 710 mm

- Payload: 7 kg

- Repeatability: ±0.02 mm

- Maximum object size: 400 x 400 x 200 mm3

Module overview – tailored to your requirements

During the planning phase, we work with you to select the appropriate modules for your test cell. From integration with your production line to suitable environmental technology – our equipment is precisely tailored to your process.

Plant integration & communication

Profinet

OPC UA

Siemens Beckhoff I/O

MES/ERP integration

Barcode/ QR/ DMC reader

EtherCAT

EtherNet/ IP

REST API/ HTTP

Handling & Accessibility

Linear axes 1µm accuracy

Rotary tables

Goods carrier pickup & handover

AGV connection

Damping with granite

Environment & Safety

ISO5 FFU cleanroom filter

ESD-safe design

Safety light curtain

Lifting door / automatic safety door

Design as a cobot

Signal lights

Status indicator

Data & Software

Recipe management

User roles

Audit Log

Process logging

Test report export (PDF/CSV)

Traceability module

Maintenance & Service

Remote maintenance Anydesk Teamviewer

Maintenance indicator

Service intervals

Calibration modules

High-end sensors

Matrix camera up to 65MP

Line scan camera, TDI

3D profile section sensor

Chromatic confocal/ line

Chr. conf. line sensor

Optical coherence tomography (OCT)

3D structured light

Laser scanning microscopy LSM

Optical micrometer

High-precision sensors

The ROBOT.SPECTOR integrates state-of-the-art measurement technologies for maximum precision. From chromatic confocal sensors and laser scanning microscopy to optical micrometers and OCT – we combine the optimal technologies for your specific requirements.

Our sensors achieve measurement accuracies in the micrometer range and enable the reliable detection of even the smallest defects, scratches, nicks, dents, pores or cracks.

Detect even the smallest deviations with micrometer accuracy and ensure the highest product quality through precise measurements in all dimensions.

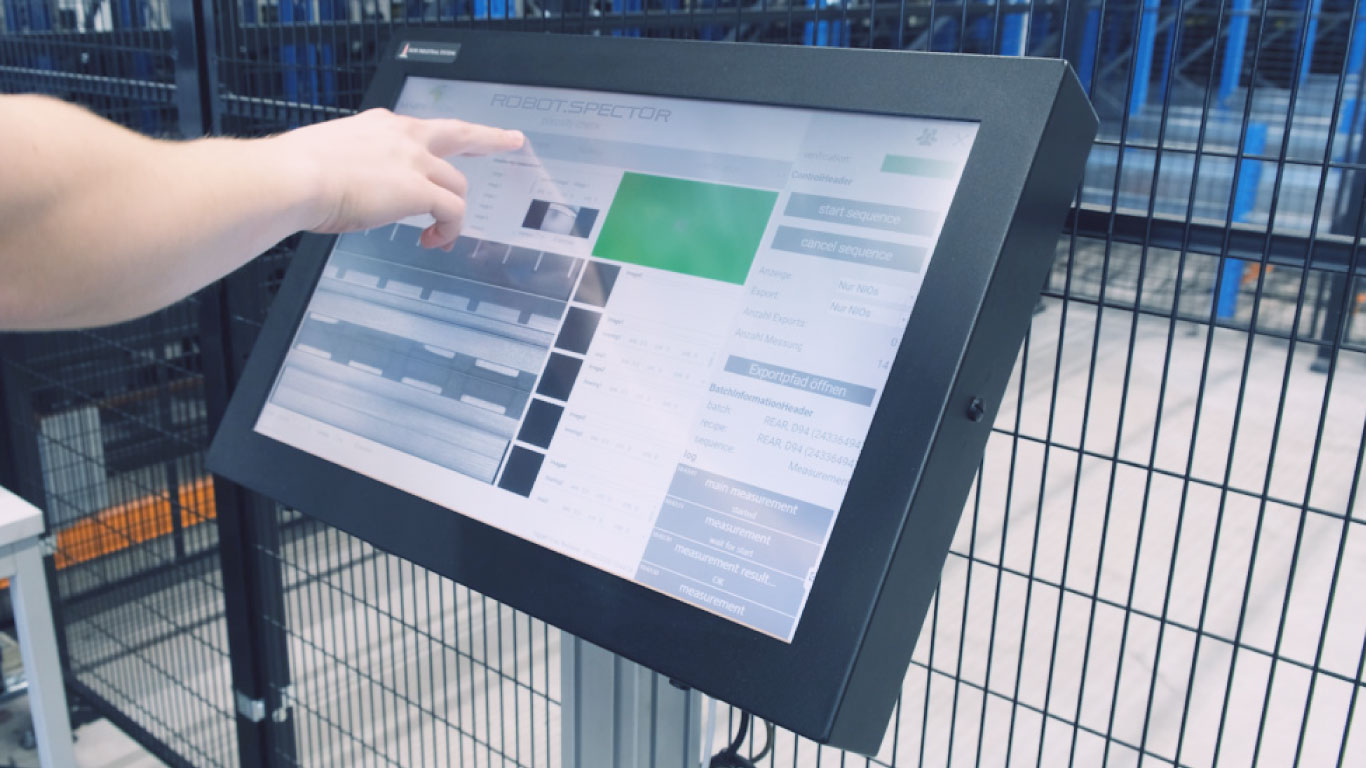

Data handling, Halcon and AI

With our vision software, we combine HALCON's leading machine vision technology with our own AI and deep learning solutions (object segmentation, anomaly detection & classification). This combination enables unprecedented inspection accuracy, allowing even complex and difficult-to-detect defects to be identified.

Our platform forms the software basis for the ROBOT.SPECTOR and enables fully integrated acquisition, processing and storage of all test data.

Our platform offers extensive analysis capabilities and ensures that all data is securely stored and available at all times.

Adaptable processes and digital twin

With the ROBOT.SPECTOR, you retain full control over your testing processes. The intuitive user interface allows you to customize test recipes, create new test scenarios, and optimize parameters.

Our digital twin enables the virtual simulation and optimization of testing processes before they are implemented in real production.

ROBOT.SPECTOR in customer projects

Our customers increase their throughput, inspect more precisely, and demonstrably deliver better quality with ROBOT.SPECTOR. The following references show how our inspection cells measurably improve production processes – with less waste, higher process reliability, and maximum transparency.

High-precision inspection system for miniaturized medical technology components

A leading manufacturer of miniaturized medical technology components relies on our state-of-the-art testing system to reduce manual inspection processes, increase production efficiency, and ensure maximum accuracy. Thanks to the combination of 2D and 3D inspection technology, even the smallest surface deviations can be reliably identified – for consistently high product quality and optimized production processes.

0.2 µm

Defect size in Z direction

258 %

Higher throughput

Compact 360° quality inspection in UV and visible areas

RJ-Lasertechnik uses the ROBOT.SPECTOR for fully automated 100% visual inspection in the visible and UV spectra. The inspection cell is equipped with a rotary table and is specifically designed for space-saving use in cleanrooms. This allows the customer to scalably automate their quality control and document it seamlessly.

30

Inspection views per component

3.2 µm

Pixel resolution

Inline testing system for cardiovascular implant components

A leading manufacturer in the field of CRM medical technology relies on our fully automated inline testing solution to improve quality assurance. By employing state-of-the-art technologies – including optical coherence tomography (OCT), a polarization-sensitive matrix camera, and on-the-fly focus stacking – 34 relevant component features are precisely captured. Robot-assisted handling and standards-compliant data documentation enable efficient and audit-compliant testing.

0.005 inch

Minimum distance

320 %

Increased throughput

Robot-guided DMC verification

A manufacturer of precision components uses the ROBOT.SPECTOR to inspect Data Matrix codes. Thanks to its modular design, different scanners can be flexibly integrated into the robot – tailored to the component, surface, and code type. The software enables the automatic scanning of any grid pattern – quickly, reliably, and in compliance with audit requirements.

1.6 years

Amortization period

230 %

Increased throughput

Our project approach in three phases

With our 3-phase model, we structure the entire life cycle of your testing project – from project preparation to plant implementation and service & maintenance.

Phase 1

Joint briefing, clarifying requirements, and feasibility study.

It's important to us that you have an experienced contact person. During this phase, you will be supported by one of our managing directors.

2. Feasibility study with initial tests

3. Creation of concept and offer

Phase 2

: From concept to finished plant.

This phase is managed by one of our technical project managers.

2. Design Qualification (DQ)

3. Factory Acceptance Test (FAT)

4. Commissioning Test (SAT)

Phase 3

Availability and reliability are our top priorities.

Our service team is always available to assist you.

2. Maintenance

3. Spare parts supply

ROBOT.SPECTOR ROI Calculator

Calculate your potential savings and return on investment with ROBOT.SPECTOR

Based on an average reduction in the reject rate of 35%

Based on an average reduction in testing time of 70%

Time until full amortization of the investment

Return on Investment over a period of 3 years

Your individual ROI analysis

Based on your input, implementing ROBOT.SPECTOR would result in annual savings of €120,833 . The investment would pay for itself after 1.2 years and achieve 142%

Contact us for a detailed analysis tailored to your specific requirements.

Dr. Nicolai Brill and Dr. Ulrich Marx

The founders and managing directors of MABRI.VISION GmbH

Do you have any questions?

Our measurement technology and automation experts will be happy to advise you!

Phone: +49 241 5652 7930

Email: vertrieb@mabri.vision