VISION.SPECTOR TIRE DMC

Reading bridge for QR codes and Datamatrix codes on tires

VISION.SPECTOR TIRE DMC

Reading bridge for QR codes and Datamatrix codes on tires

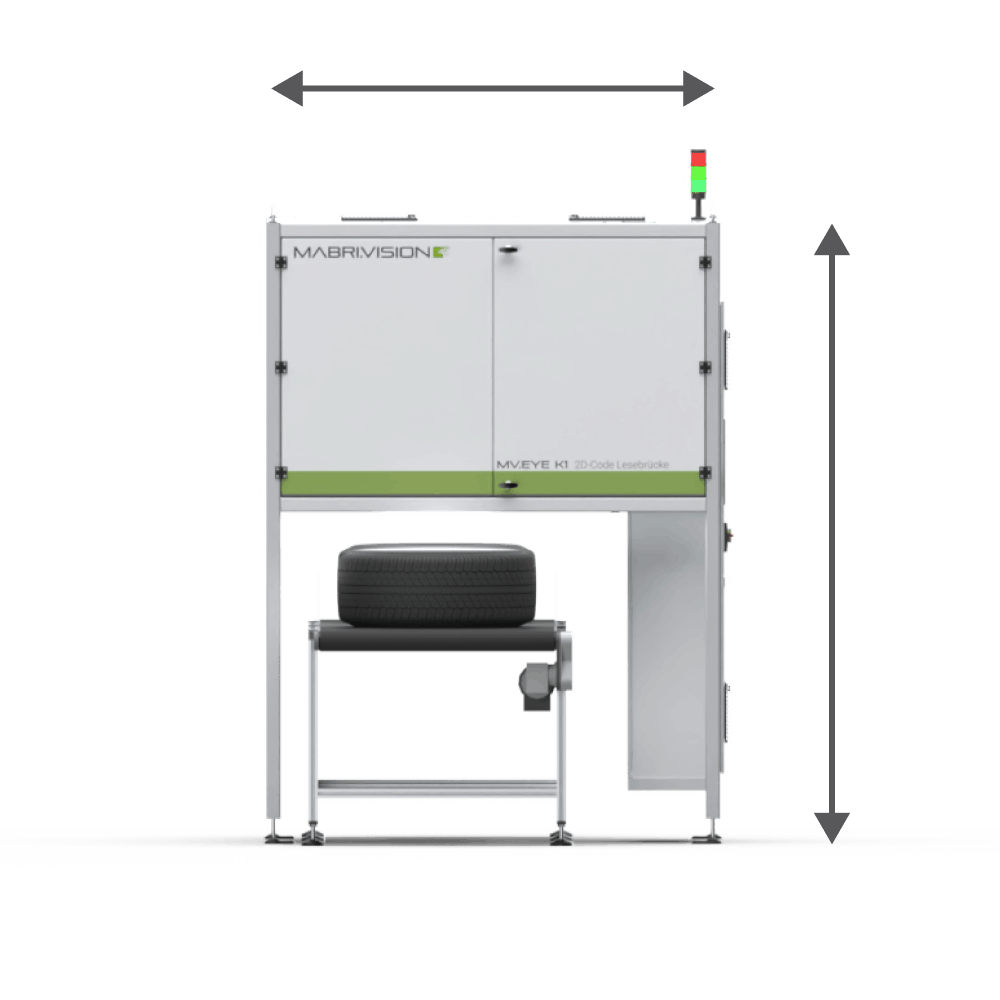

The MV.EYE K1 reading bridge from MABRI.VISION was developed for the rapid detection and reading of 2D codes on tires. Molded or laser-etched codes, such as Data Matrix and QR codes, are read continuously during conveying with a best-in-class read rate of >99.8%. Applications include the production, assembly, and storage of passenger car and truck tires.

Applications

- Reading QR and DataMatrix codes on tires

- Code quality assessment

Areas of application

- Tire fitting

- Tire production

- Tire storage

Industries

- Automotive

- E-Mobility

Easy integration

The reading bridge can be easily integrated into existing production processes. Integration is achieved via standard interfaces

Always sharp

The MABRI.VISION MV.EYE K1 testing system is equipped with a high-speed focusing system that guarantees high read rates for different tire widths.

High-speed camera

The high-speed camera system enables the reading and evaluation of 2D codes at conveying speeds of up to 1 m/s.

smart interface.

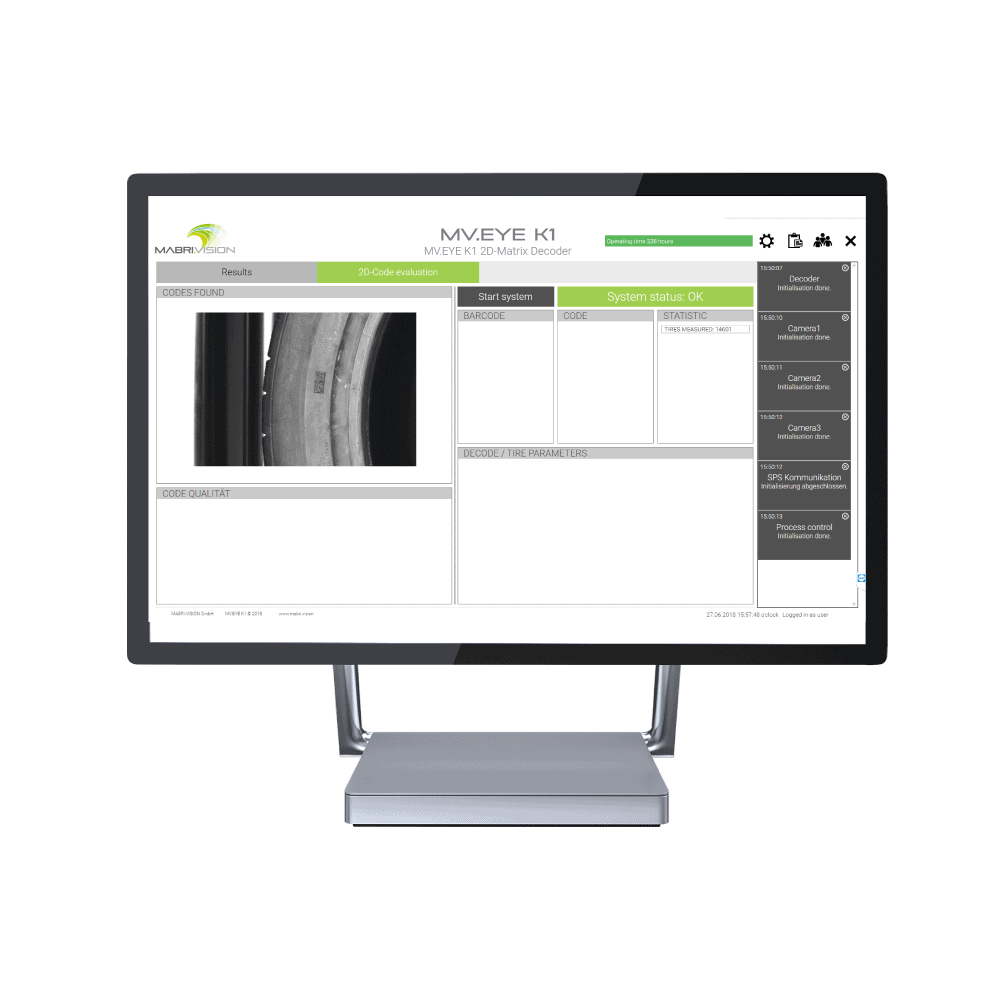

Benefit from a large display for visualizing and analyzing the tests. Interfaces to your systems can be expanded as needed (Profinet, Profibus, Digital I/O).

Scalable design.

The reading bridge can be easily integrated into existing production processes. Integration is achieved via standard interfaces.

Databases.

Codes read, code quality, and read rates can be recorded in databases.

Specifications.

Universal: versatile in its applications.

automotive

Registration of car and truck tires using QR codes and Data Matrix codes. The codes are read from the moving object using a high-speed focus system.

Suppliers

Reliable 2D code recognition in production, logistics, and further processing. The testing system is scalable and can be adapted to your production requirements.

Dealers & Workshops

Complete traceability of the entire tire lifecycle. Tracking from production to disposal. Benefit from an intuitive interface.

Why MABRI.VISION

Innovative solutions, our passion!

Innovative solutions, our passion!

AI, Processing, Control - a software platform

AI, Processing, Control - a software platform

A strong team, always there for you.

A strong team, always there for you.

End-to-end solutions, all from a single source.

End-to-end solutions, all from a single source.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision