INSPECTION OF INTERNAL SURFACES

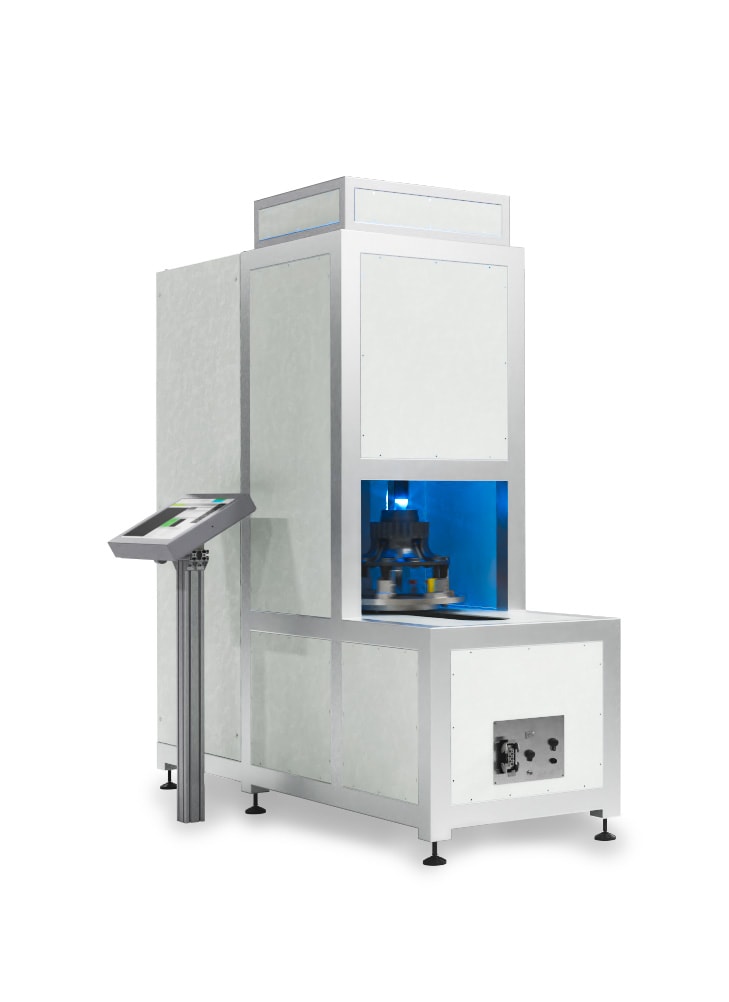

Use our VISION.SPECTOR to check the inner surfaces of rotationally symmetrical surfaces.

Our inspection system is specifically designed to examine defects on internal rotationally symmetrical surfaces during production. This allows you to ensure that the internal surfaces of these components are free of defects.

Why is in-process testing of these surfaces so important?

Internal surfaces, such as those of turbine housings, brake cylinders, bearing surfaces, or gearbox housings, play a crucial role in the subsequent reliability and functionality of your components. Defects such as scratches, dents, chip indentations, or pores can significantly impair these qualities.

Precise in-process testing of various test characteristics is crucial to ensure that your rotationally symmetric surfaces meet the highest quality standards and that the performance and safety of your products are guaranteed.

Indispensable for any rotationally symmetric surface

Versatile defect detection

We detect various types of defects that can be exposed during production processes such as milling. These include, for example, grooves, pores, scratches, dents, and chips. We use modern methods such as anomaly detection for this purpose.

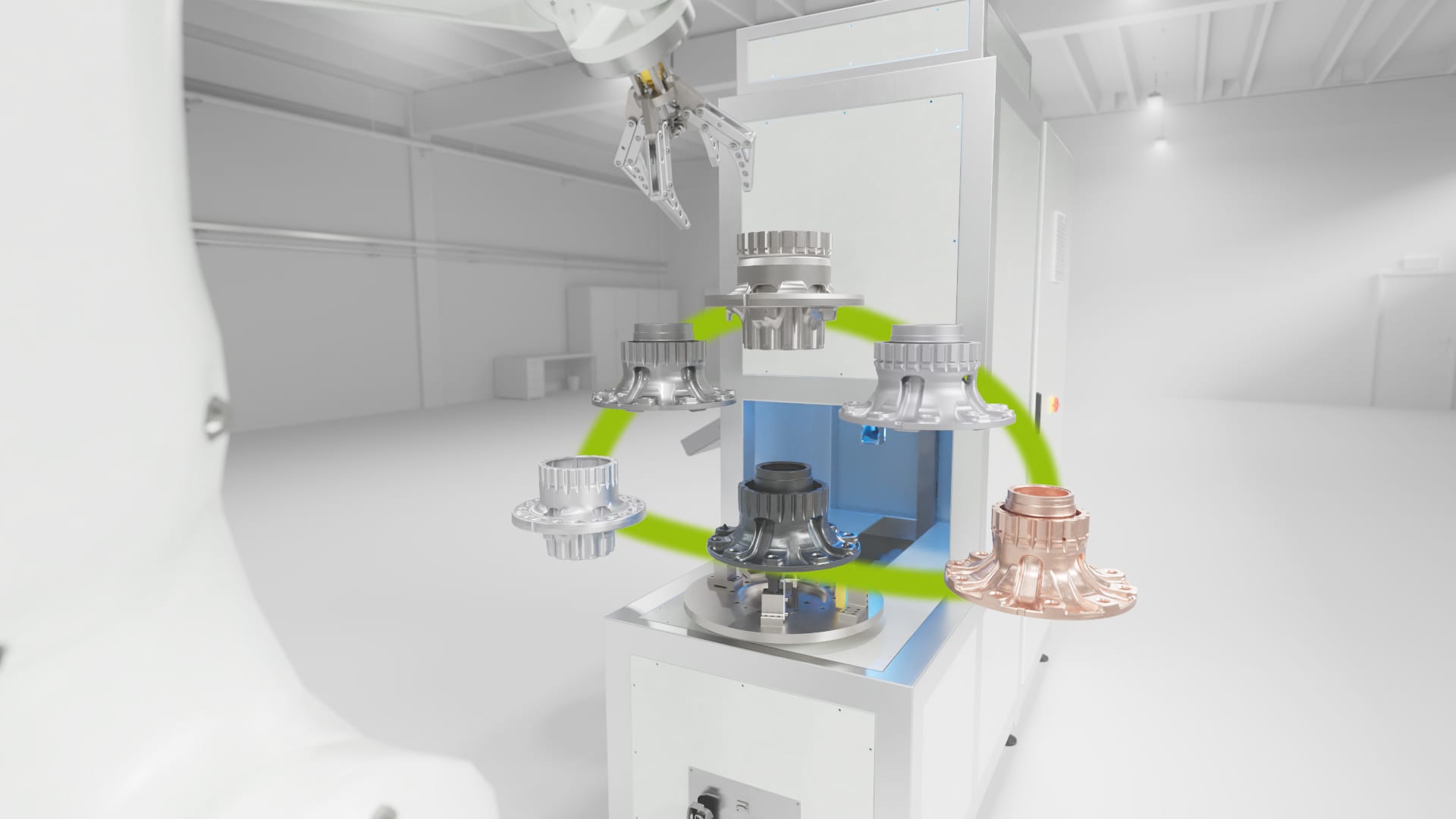

Flexible component size

Thanks to a flexible carrier unit, the testing system can test larger or smaller versions of components without requiring any system modifications. A recipe database allows for quick changeovers.

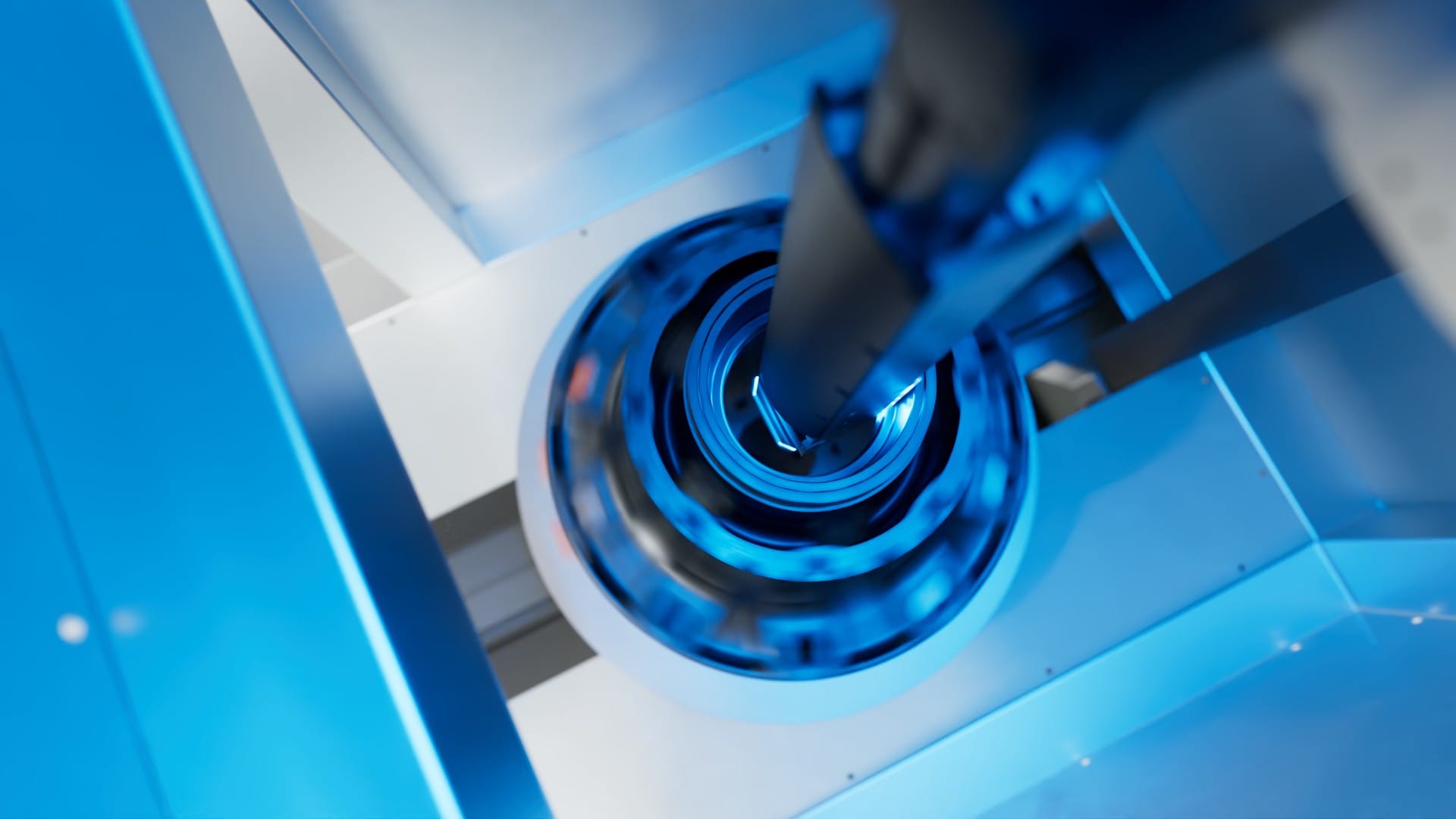

High performance and speed

With a mean rotation speed of 180°/s, we measure test parts in sync with the production cycle. Thanks to the movable Z-axis with a travelable measuring height of 350 mm, multiple surfaces with different diameters can be inspected in a single operation.

Precision at the highest level

With a pixel resolution of approximately 25 µm, our system detects pores as small as 0.3 mm. With a large field of view of 40 mm, we can cover even large interior surfaces in just a few seconds.

Application examples for rotationally symmetric surfaces of various components

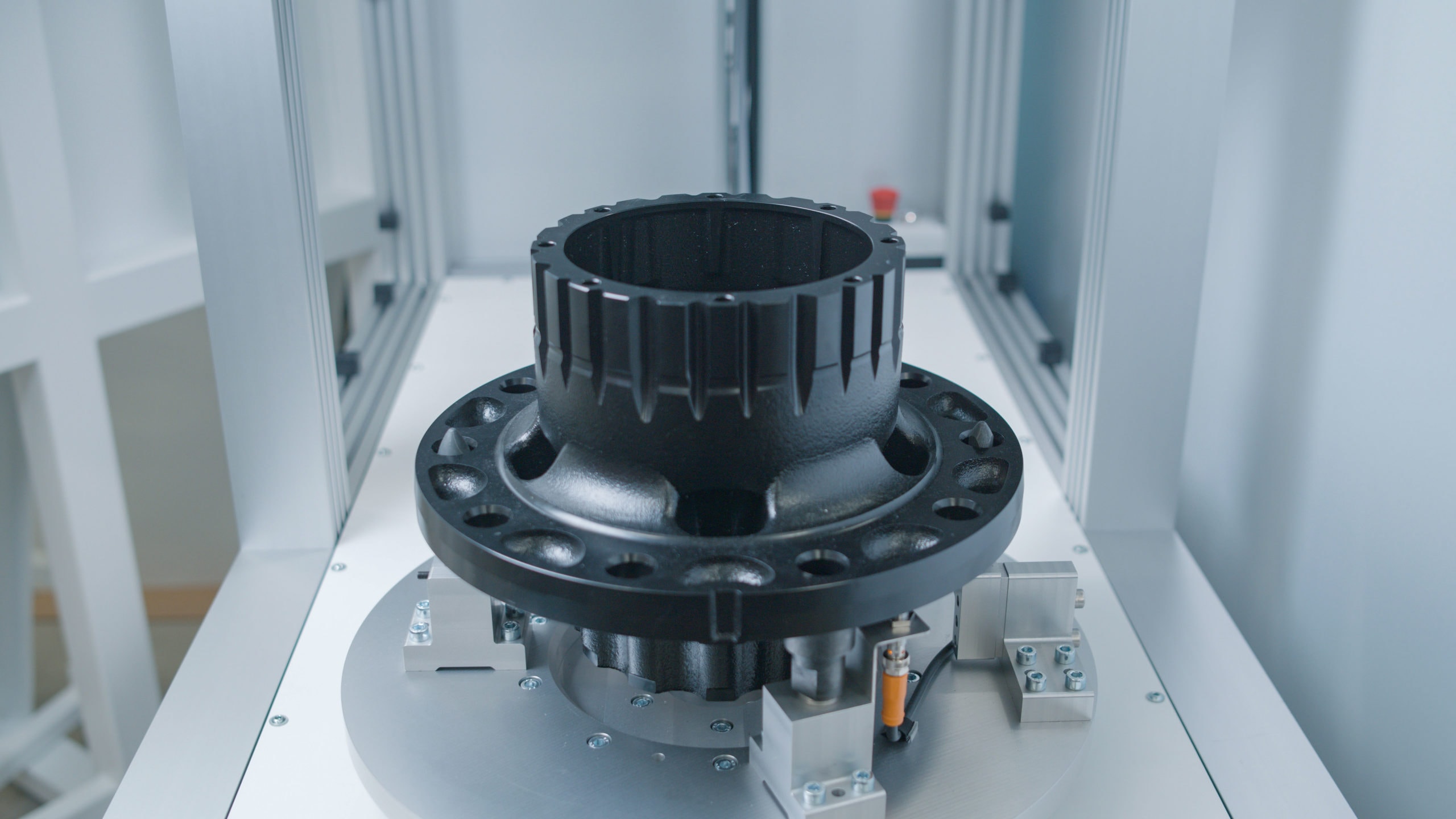

Testing of wheel hubs

The internal structure of wheel hubs plays a key role in driving safety. Irregularities or defects can lead to component failure, therefore a thorough inspection is essential.

Final inspection of gearbox housings

Gearbox housings require precision for efficient power transmission. Defective internal surfaces can cause long-term damage and negatively impact efficiency through frictional resistance.

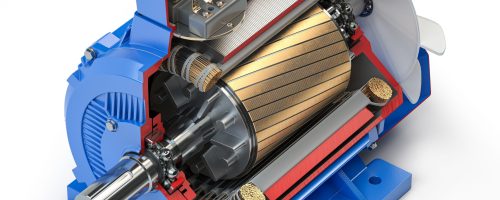

Testing of stator housings

In electric motors, stator housings are crucial for energy efficiency and longevity. MABRI.VISION detects material defects or irregularities at an early stage.

Inner walls of pressure vessels

Here, the integrity and tightness of the container are of utmost importance to ensure safety and performance.

Turbine and pump housing

Tolerances and smooth surfaces are crucial for the flow of liquid or air to ensure performance, durability, and efficiency.

Final inspection of bearing bores

Precise drilling in bearings is essential for machines or vehicles to minimize vibrations and wear.

Precision meets innovation.

Discover how our machine vision inspection systems make a difference. Talk to an expert!

FAQs

What are the minimum and maximum diameters into which immersion and testing are possible?

The minimum diameter we can currently dive and inspect ranges from 95 mm to 148 mm. The maximum diameter is not explicitly defined. In such cases, we would position the optics using the feed axis to optimally adapt to the diameter being inspected. It should be noted that the optical field of view is approximately 40 mm. This allows for flexible adjustment to different diameter ranges within the aforementioned minimum and maximum values.

Which z-range can be scanned?

We can perform scanning up to 350 mm in the z-axis. This is due to the fact that the z-axis has a reach of 400 mm, although we must deduct a certain amount for collision safety and the optical setup. This leaves an effective measuring height of approximately 350 mm for our scanning in the z-axis.

What is the cycle time?

The time required to remove a wheel hub component from the fixture after it has been scanned once through 360 degrees is typically less than 45 seconds. This time is comprised of several process steps. We rotate the component at a speed of 180 degrees per second, capturing a complete rotation. Then, the new Z-position is approached for the next measurement. This cycle takes approximately 4 seconds in total. However, the overall time depends on the number of measurement surfaces that need to be scanned.

What are the smallest defects that can be detected?

The smallest defects we want to detect are larger than 0.3 mm. Our pixel resolution on the workpiece is approximately 25 µm, which means we are able to precisely detect and identify pores or irregularities with a size of 0.3 mm or larger.

What is the maximum possible pixel resolution?

The pixel resolution we can achieve depends heavily on the size of the measurement area. A simple rule applies: the smaller the measurement area, the higher the achievable resolution. For example, with a measurement area of 20 mm², we can achieve a resolution of approximately 12.5 µm.

For even higher resolutions, however, we would need a new optical design and possibly specialized equipment. Significant increases in resolution typically require a realignment of the optics and possibly also an adjustment of the entire system configuration.

What defects is the VISION.SPECTOR specifically designed to detect when inspecting rotationally symmetric surfaces?

The primary focus is on pore detection. However, we are also able to identify all other deviations, including scratches, discoloration, dents, foreign objects, and other defects. This detection is achieved through anomaly detection. The evaluation and filtering of potential defects is then performed using Halcon. This ensures that we can reliably detect and inspect a wide range of defects.