MV.EYE PI1

Inline inspection for surface defects on metal pipes

MV.EYE PI1

Inline inspection for surface defects on metal pipes

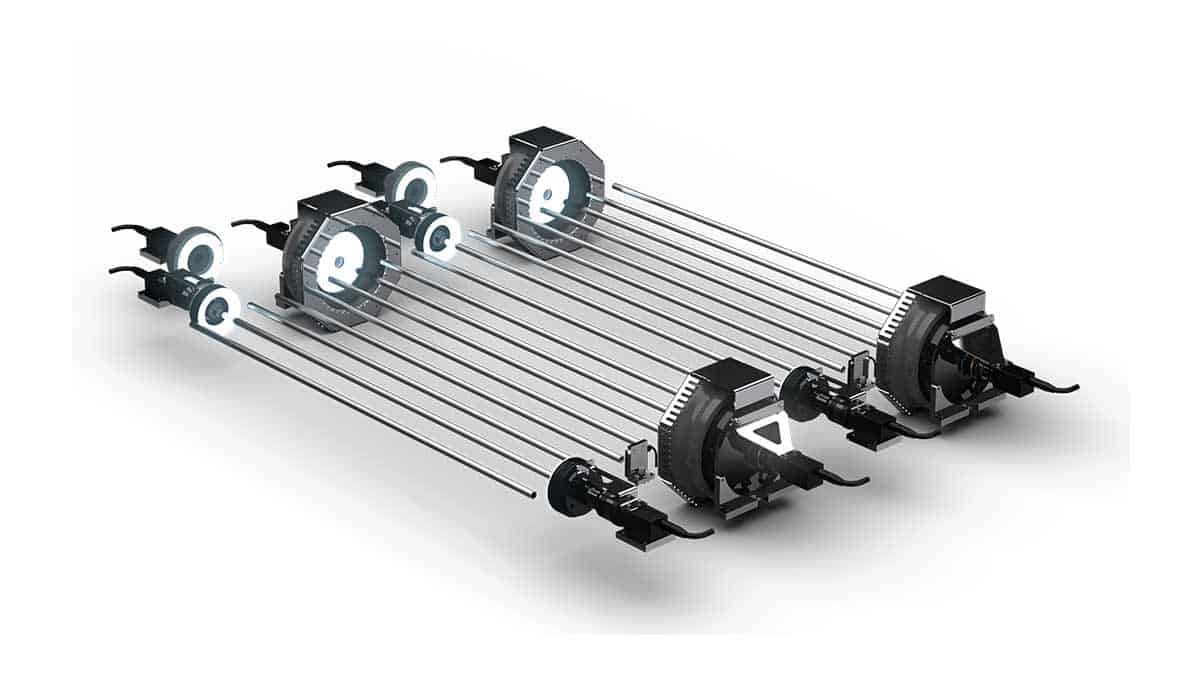

MABRI.VISION has developed the MV.EYE PI1 optical inspection system for detecting defects on metal pipes. By using multiple optics and a high-speed focusing system, defects inside the pipe and at the weld seam, for example, can be detected. The system performs a comprehensive inspection of the inner and outer chamfers as well as the outer and inner surfaces. The high speed of the inspection process enables continuous inline testing.

Applications

- Testing of metal pipes

Exams

- Internal chip testing

- weld inspection

- Inner & outer chamfer

- Shell and inner surface

Industries

- Metalworking

- Energy supply

- automotive industry

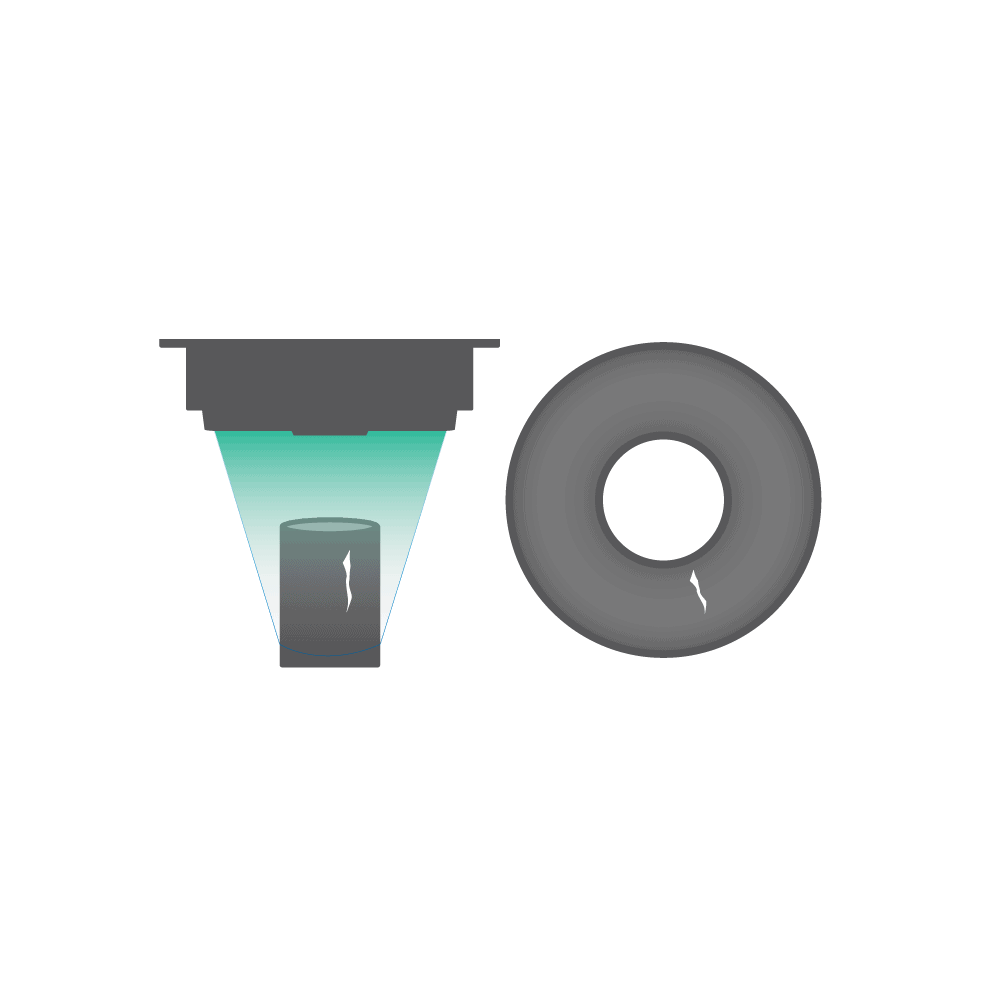

Internal chip testing

The high-speed focus system developed by MABRI.VISION generates internal images on different image planes and enables reliable internal chip inspection.

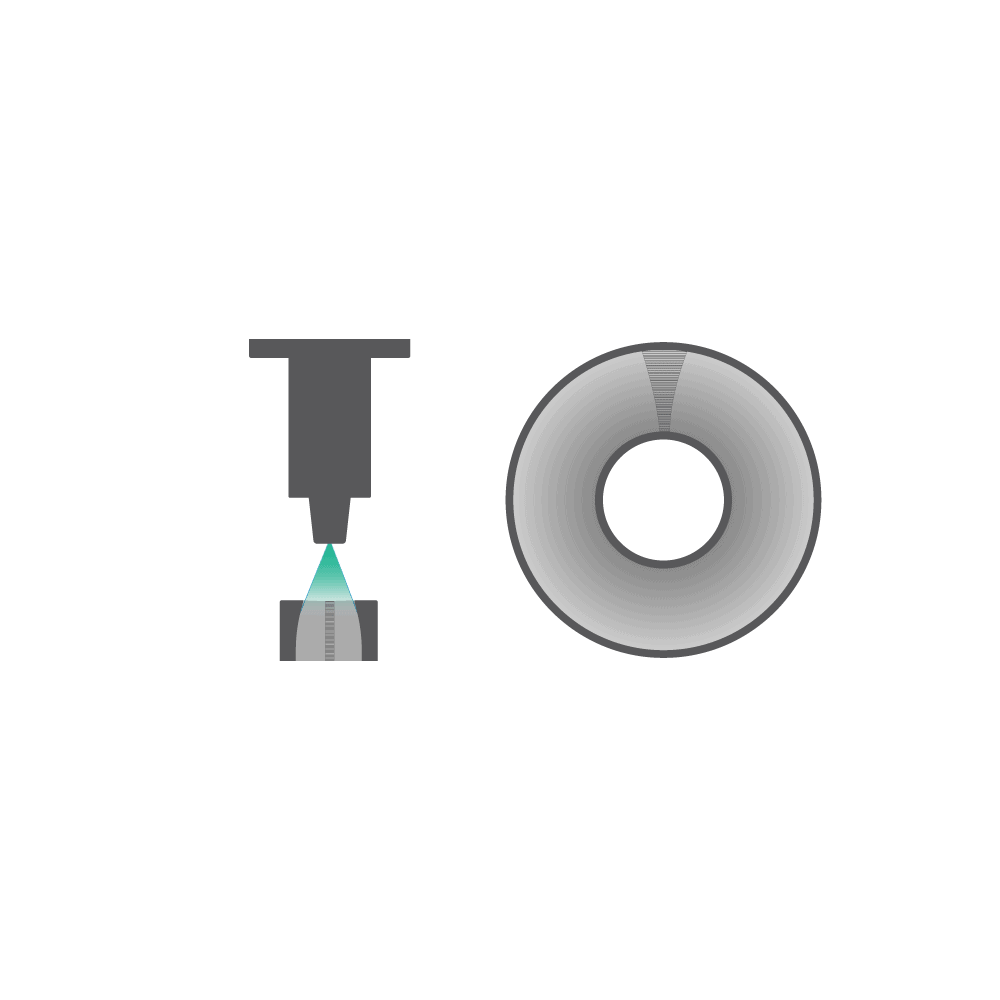

Inner & outer chamfer

Our testing system records the exact dimensions of metal tube end faces and checks both the inner and outer chamfer for presence, shape and tolerances.

360° surface area

The MABRI.VISION MV.EYE PI1 testing system ensures uncompromising testing of the outer surface of metal tubes in 360° – for optimal further processing.

360° interior surface

Our inspection system is specifically designed for the inspection of metal pipes through the use of multiple optics and offers, among other things, a 360° inspection of the inner surface.

weld inspection

The optical sensor technology of the MV.EYE PI1 testing system enables non-contact testing of welds for defects and compliance with tolerances.

High speed

The use of the MABRI.VISION high-speed focus system allows for high-speed testing of metal tubes, enabling integration into your production processes.

Specifications

Universal: versatile in its applications

METAL PROCESSING

The MABRI.VISION MV.EYE PI1 testing system is particularly suitable for comprehensive quality control of pipes in metal processing production processes.

Energy supply

Inline-capable 360° inspection of the outer and inner surface of metal tubes with a diameter of 3 – 20 mm and for use in energy supply.

AUTOMOTIVE INDUSTRY

In the automotive industry, the MV.EYE PI1 testing system is used for internal chip and weld seam inspection. Thanks to its high-speed focusing system, the inspection can be seamlessly integrated.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision