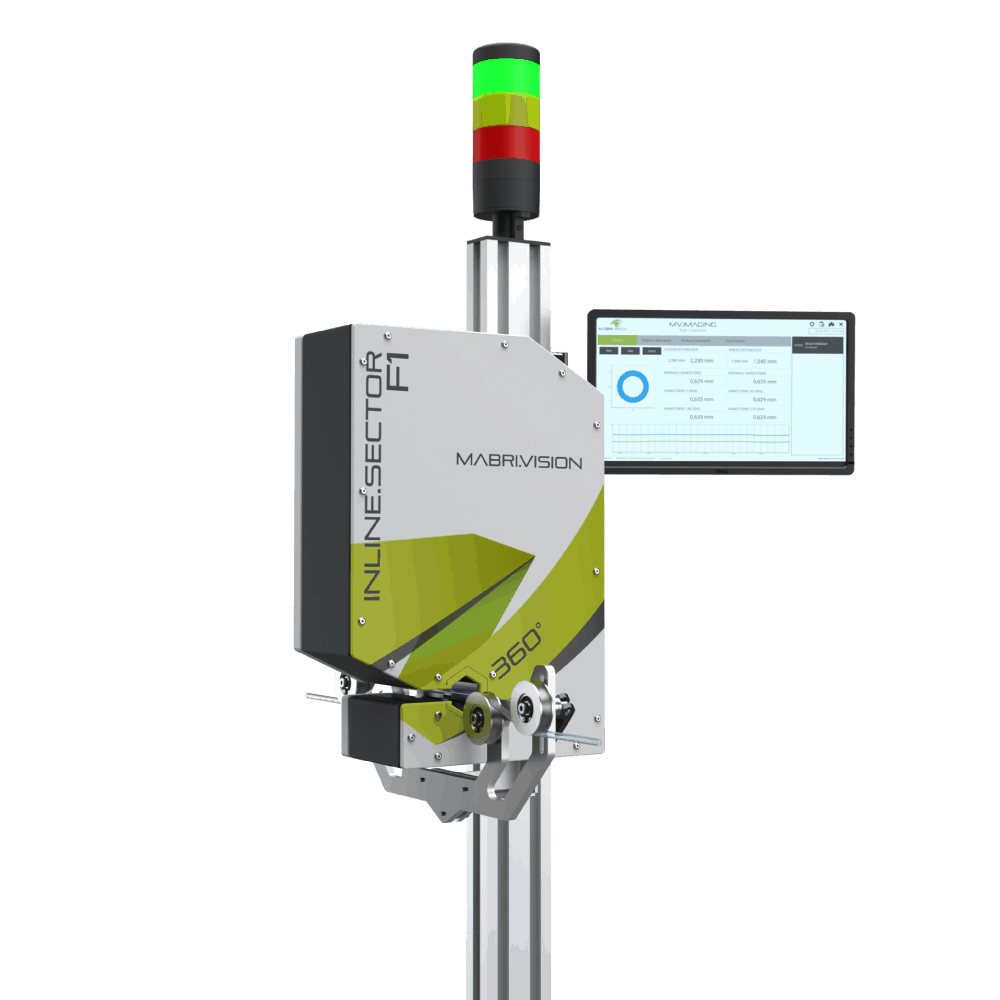

MV.CHECK INLINE SECTOR F1

Inline measurement technology for silicone hoses

INLINE SECTOR

Inline measurement technology for silicone hoses

The INLINE.SECTOR inline testing system from MABRI.VISION represents the next generation of non-destructive quality control for plastics and silicone tubing. A 360° sensor generates high-speed cross-sectional data for comprehensive testing of the geometric properties of semi-transparent tubing. These properties include, for example, inner and outer diameters, wall thickness, eccentricity, and ovality.

Applications

- Testing silicone hoses

- Testing of multilumen hoses

Exams

- Layer thickness

- 360° wall thickness

- Core offset

- Shape Surface

- Shape of inner cavity

Industries

- Medical technology

- pharmaceutical industry

Inline check

The INLINE.SECTOR inspects hoses directly in your extrusion line for applications with the highest demands. The non-contact measuring method enables, among other things, the testing of wall thickness, shape, and offset.

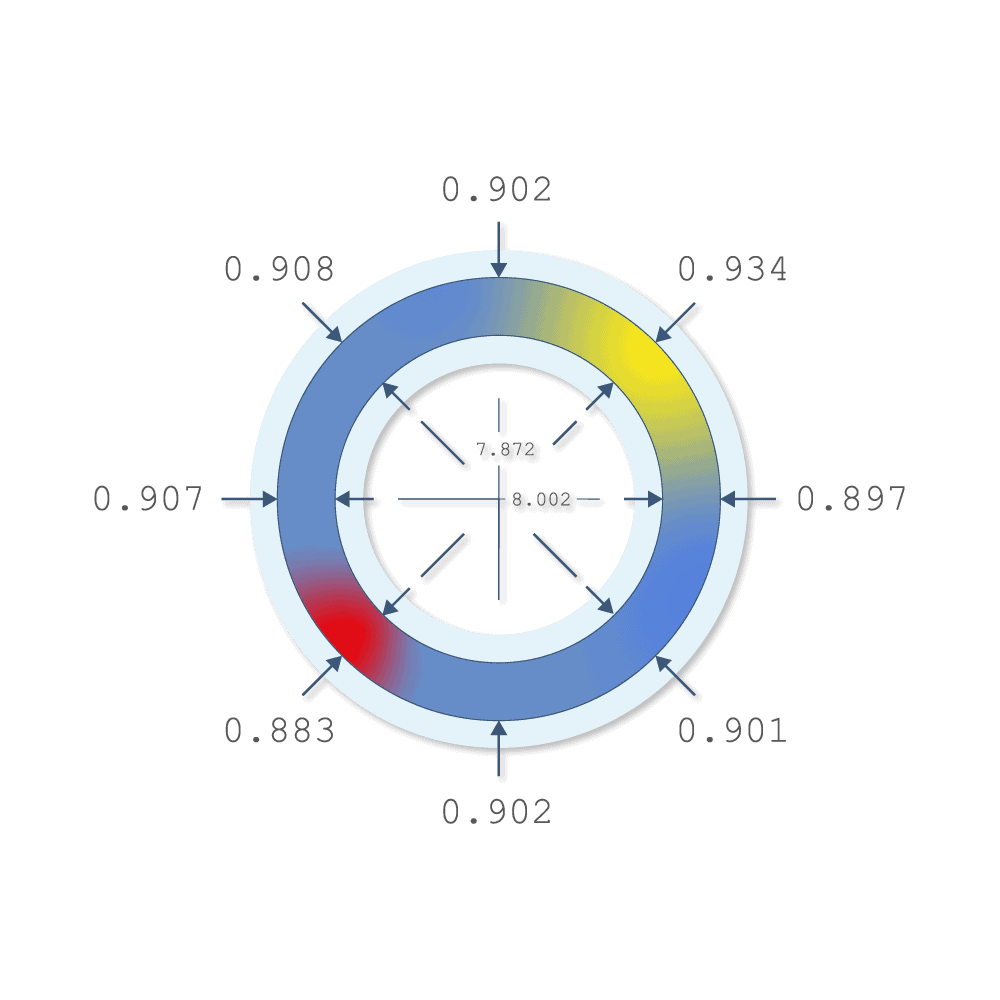

wall thickness

MABRI.VISION's inline testing system enables simultaneous measurement of wall thickness from up to 16 directions. Testing is performed simultaneously with your production and is completely non-destructive.

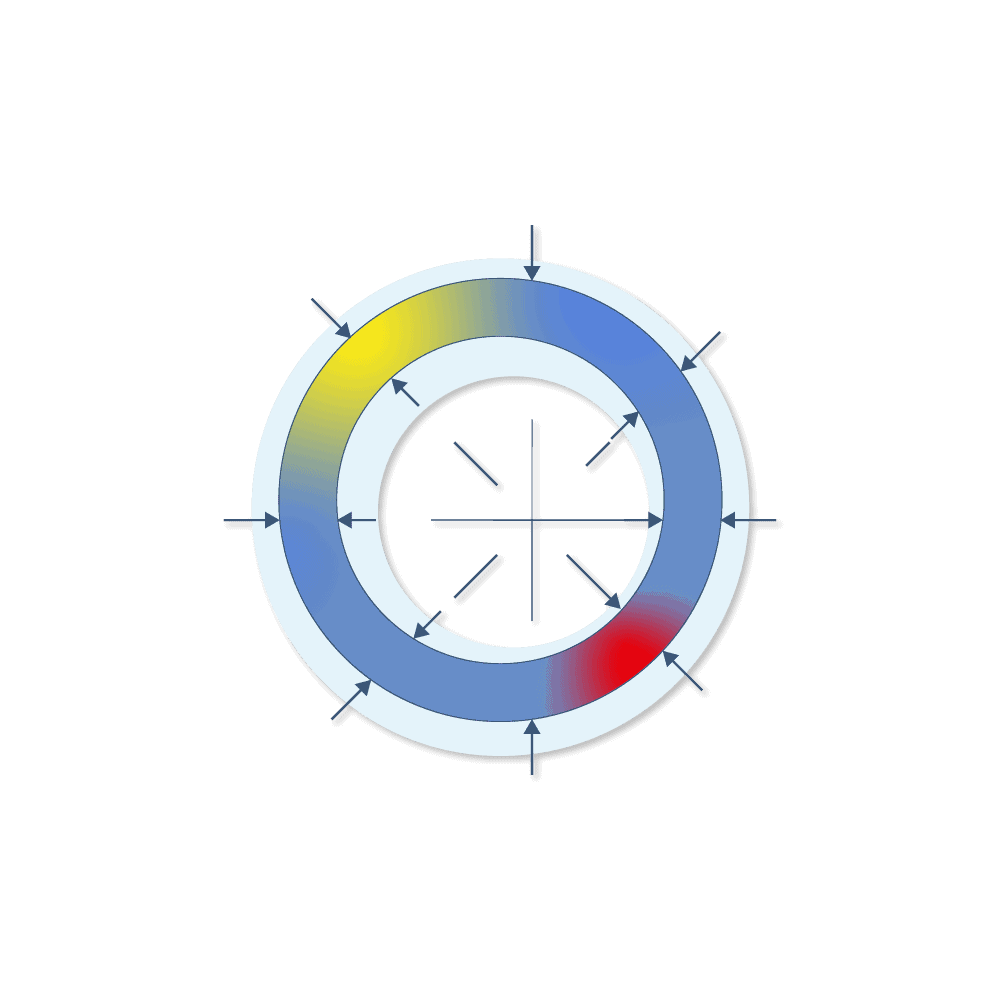

Core offset

Precise testing of core offset on semi-transparent tubes (both colorless and colored) with a diameter of 0.5 mm – 20 mm and a wall thickness of 0.1 mm – 4 mm.

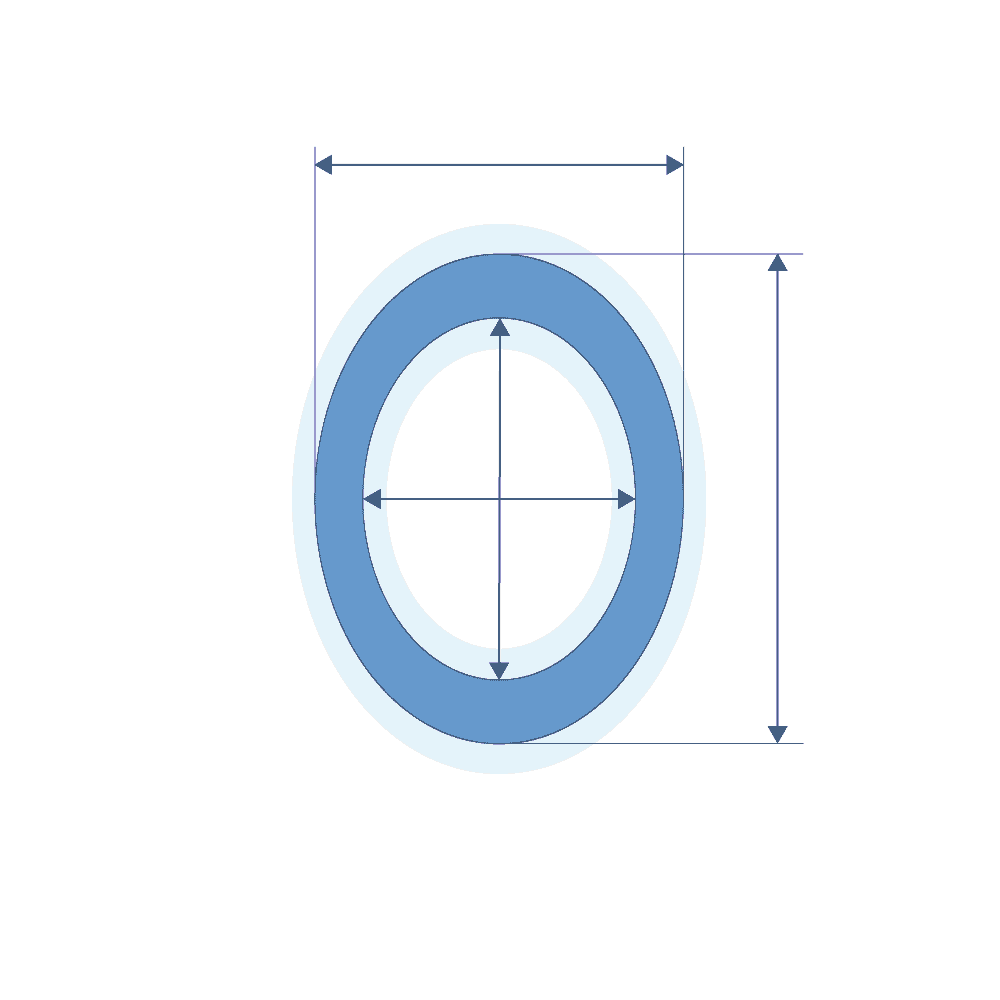

form

Measurement of inner and outer diameter, minimum and maximum wall thickness, ovality, eccentricity, and core offset. Obtain a complete cross-sectional image of single-lumen tubing.

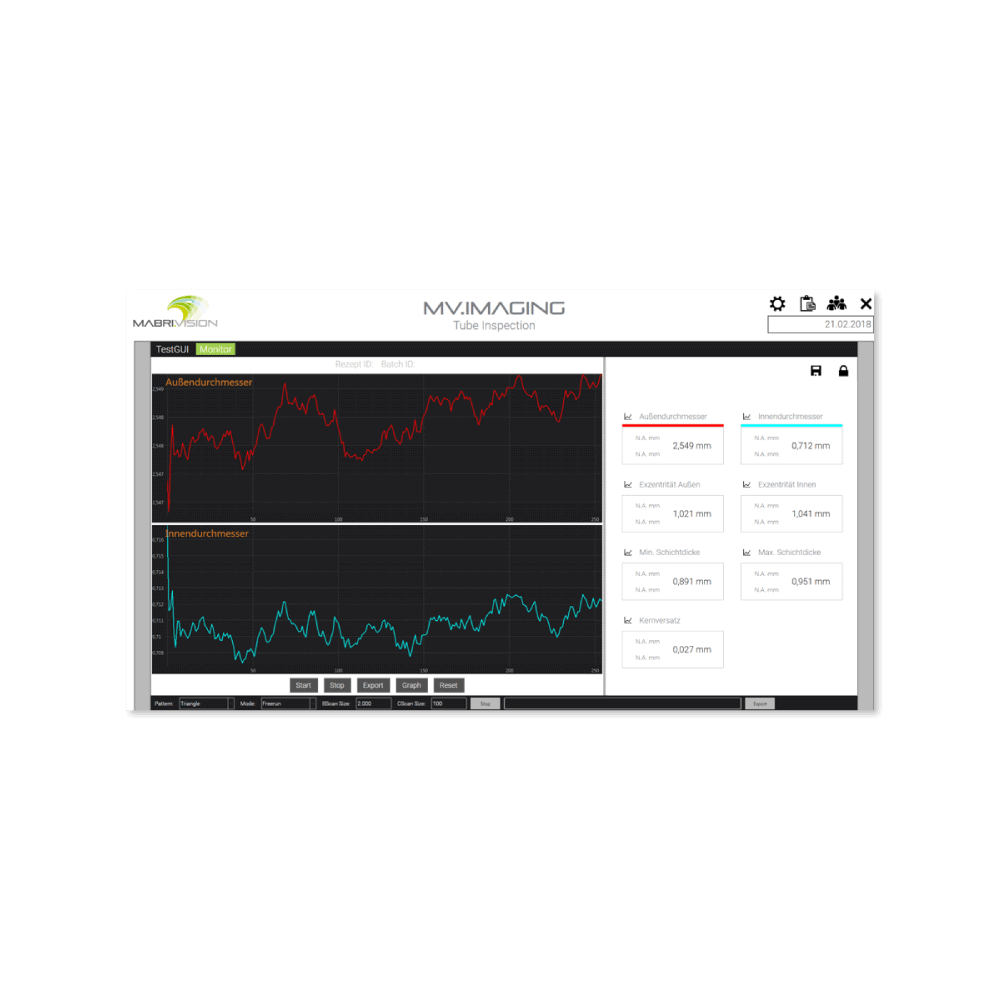

History & Statistics

All generated measurements are saved and can be analyzed and exported. The database functionality can be extended to meet your requirements, for example, to include time-series graphs for any process parameters.

clear

Benefit from a clear interface for visualizing and analyzing the tests. Interfaces to your systems can be expanded as needed (for example, Profinet, Profibus, digital I/O and analog).

Specifications

Universal: versatile in its applications

MEDICAL TECHNOLOGY

Comprehensive quality control of transparent and semi-transparent tubing in the medical industry.

INFUSION

Uncompromising inline testing of infusion tubing for defects and geometric properties.

Dialysis & Blood Donation

100% inline testing of tubing used for dialysis and blood donation.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision