MV.SENSE OCT

industrial OCT sensors

Industrial OCT sensors for your application

The MV.SENSE interferometric sensors are specifically designed for industrial applications. Whether for surface inspection, measuring the thickness of transparent materials, or conducting volumetric analyses – the various scanning functions offer a wide range of application possibilities.

Are you looking for a complete solution? MABRI.VISION offers turnkey solutions for your application. We cover all services: system design, construction, control cabinet building, cabling, and interface programming.

One sensor – many possibilities

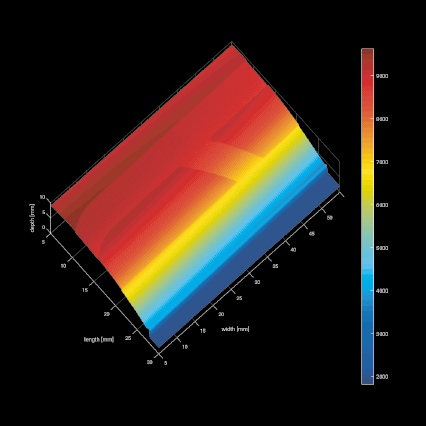

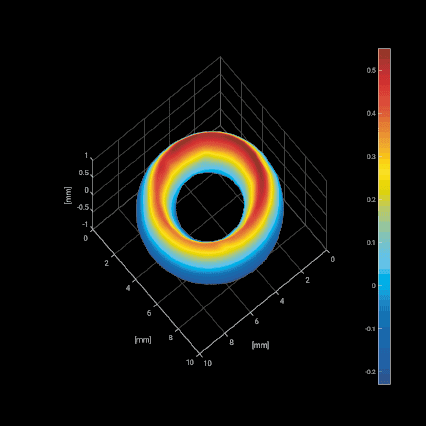

Our OCT sensors offer various scanning functions. The combination of controller, sensor, and software enables highly precise measurement of surfaces, distances, layer thicknesses, and volumes or internal material structures. The specific measurement mode depends on your application.

surface

Layer thickness

tomography

Diverse application possibilities

The various scanning functions offer diverse application possibilities, for example in the packaging technology, automotive, pharmaceutical and medical technology industries.

Depending on the application, we offer suitable sensors. Measurements can be taken in 1D, 2D, and 3D. The measurement process requires no additional axes or kinematics, as the beam shaping is performed within the sensor itself, thus offering maximum flexibility.

We provide you with all the building blocks from a single source – from planning and the development of suitable software solutions to the clearly presented visualization of the collected data.

Operating principle and technology

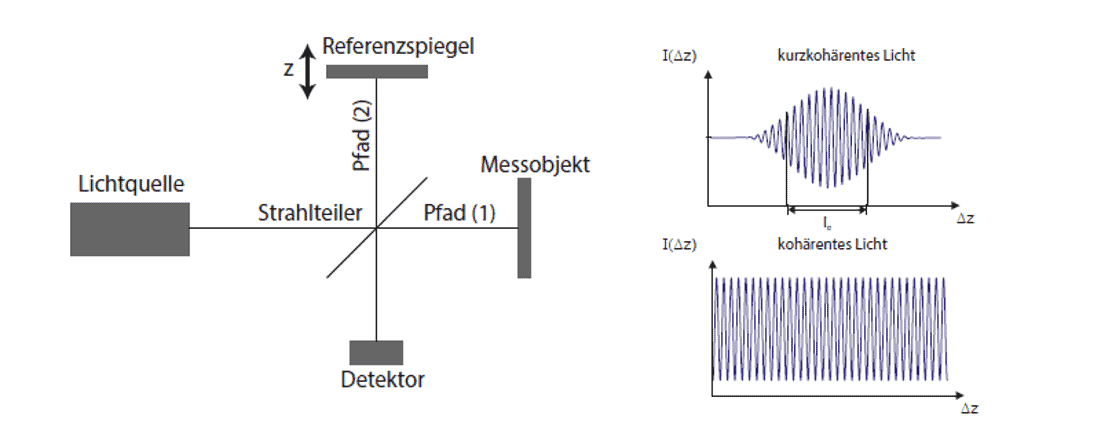

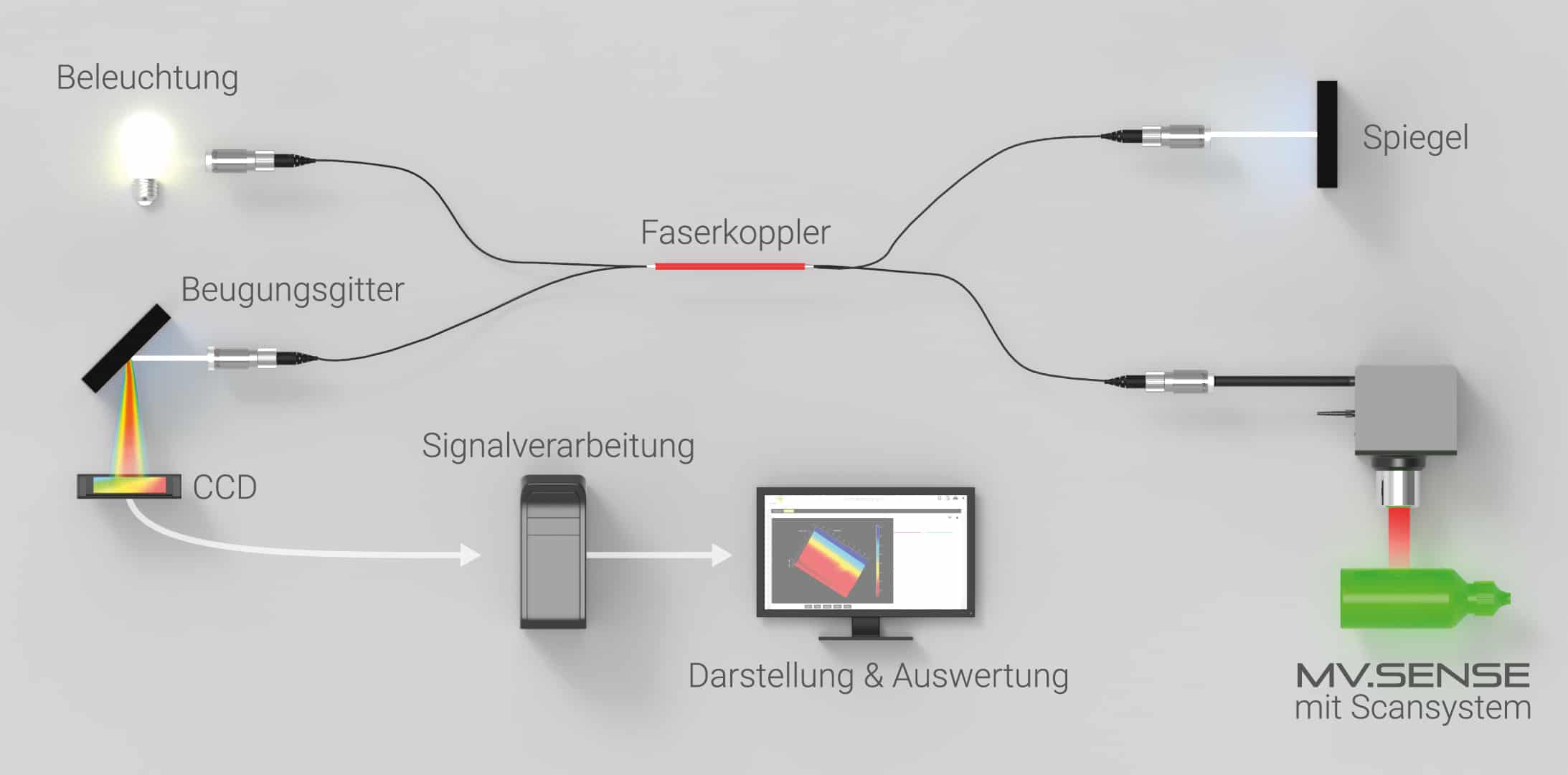

Our sensors are based on the principle of white light interferometry, offering the advantage of fast, pinpoint measurement. This combines the high precision of a classic white light interferometer with the advantages of light section sensors, such as flexibility and suitability for production.

Different reflection properties enable the testing of multilayered, translucent materials. At the heart of our sensor technology is the use of a broadband light source with a spectral evaluation unit. The backscattered light interferes with a predefined reference path.

Due to the low coherence of light, absolute distance measurements are obtained. Multiple measurement points can be combined to form a single image. Depending on the configuration, point-based measurement rates of up to 250 kHz are achieved. The measurement is performed without additional axes or kinematics.

More than just a sensor

With MV.SENSE, we offer you a complete solution for all things OCT. From planning automated inspections and providing suitable software solutions to clearly presented visualizations of the collected data, we supply all the necessary components for your machine vision solution from a single source .

Software solutions

Our software framework MV.IMAGING offers you maximum flexibility. In addition to basic functionalities such as the recording, analysis, and storage of measurement data, customized software packages are available for various applications. Features such as user management, databases, and data visualization are integrated according to your requirements.

Machine vision

We combine our OCT sensors with industrial machine vision platforms to guarantee efficient inspection of dimensional accuracy, presence, defects, pores, voids, runout, position, and 3D form measurement. In addition to our MV.SENSE sensors, we also use matrix and line scan cameras as well as profile sensors to implement vision solutions.

automation

We offer suitable automation modules for our MV.SENSE sensors. Using the appropriate PLC modules, we can integrate all common hardware and software interfaces according to your requirements. By combining suitable handling systems and conveyor technologies, our testing processes can be seamlessly integrated into your production.

Feasibility studies

Suitable sensors for your test

Which technology is best suited for your testing needs? Our OCT experts will create an optimal test design based on your specifications. They have access to various sensors from the MV.SENSE series, which cover a wide range of requirements.

Optimal implementation of the testing process

Based on your specifications, we design the testing processes to replicate the industrial environment as realistically as possible. Our goal is to achieve robust and efficient testing that functions flawlessly and reliably even under adverse conditions.

Comprehensive analysis of the possibilities

A clear definition of limit patterns and test tasks is crucial for the implementation of the test. To ensure the subsequent performance of the test system, particular attention is paid to its dimensioning.

Consultation and interpretation

Crucial for the successful deployment of an OCT system are optimal design and the selection of suitable sensors and controllers. Only with correctly dimensioned components can the relevant characteristics be reliably detected.

Benefit from our expertise in the planning and design of OCT testing processes.

Performance

up to

up to

up to

Specifications

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision