High-speed microscope for your production

MICROSPECTOR

Need to inspect the smallest components and structures in real time? Our high-speed microscope, MICRO.SPECTOR, automates the inspection of microstructured components. The MICRO.SPECTOR detects even the smallest defects and shape deviations, reliably rejecting defective parts. The MICRO.SPECTOR can be operated as a stand-alone solution or as a fully automated in-process inspection system.

HIGH-SPEED INLINE TEST

of microstructured components

Our MICRO.SPECTOR enables fully automated inspection of microstructured components and products for defects, shape deviations, and dimensional accuracy. Defective parts are automatically detected and can thus be removed from the production process.

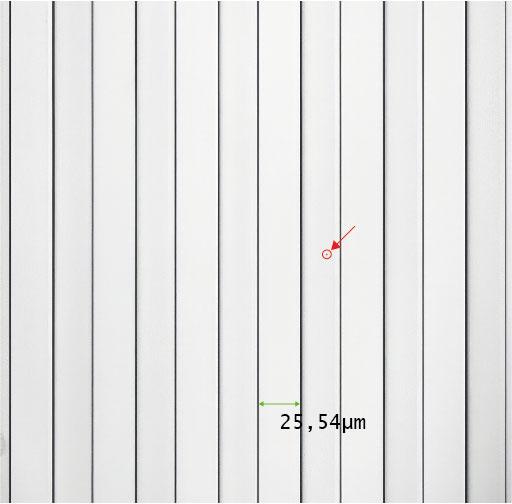

The MICRO.SPECTOR has a modular design, allowing it to be used as a stand-alone system or as a fully automated solution within production. With barcode tracking, FFU (Functional Frequency Unit), lifting door, auto-loading, cleaning, and many other modules, we can tailor the system precisely to your needs. Depending on the configuration, we work with pixel resolutions starting at 0.48 µm. Fast data acquisition and processing ensure cycle times that match the production cycle.

With our MICRO.SPECTOR, you can reliably and quickly inspect large quantities – simply impossible by hand.

MICROSPECTOR

The most important facts at a glance:

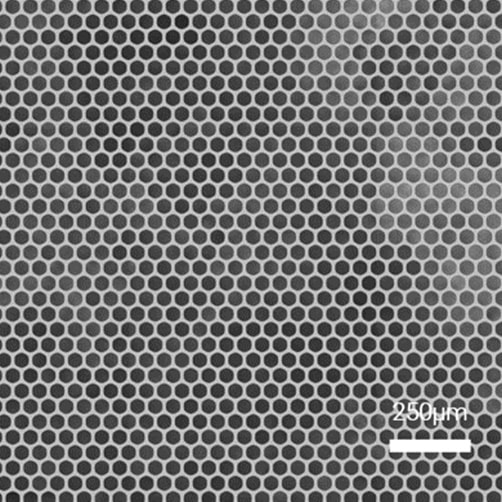

High resolution

Our standard configurations are 0.48µm, 0.75µm and 3.5µm pixel resolution

Fast

Our high-speed version uses a multi-line camera with 17,824 pixels and up to 142kHz

Automated

Our modules: automated test recipes, automated assembly and automated feeding

large area

In our standard configuration, we scan up to 300 x 300 mm²

Cleanroom solutions

Whether stand-alone or process-integrated - we offer FFUs, lifting doors, code readers or cleaning systems

End-to-End

From test design on initial samples to full automation – we offer turnkey solutions

integration

Just the way you need it

Internal chip testing

Production QC laboratory

Production 100% inspection

Insights

Smart solutions

QC solutions

Our MICRO.SPECTOR is designed for direct integration into your production chain. From barcode tracking, change log, audit trail and user management to direct connection to your management level, we offer all the necessary tools to make your QC more efficient and reliable.

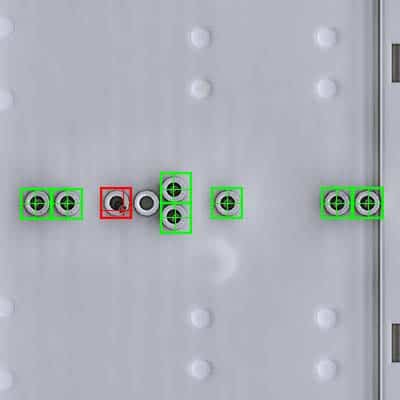

Microscopic examination & maintaining an overview

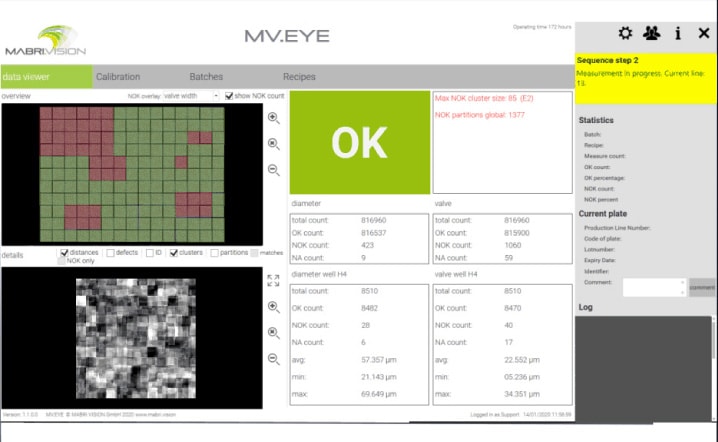

Our MICRO.SPECTOR systems are equipped with high-resolution vision systems to detect microscopic defects and verify dimensional accuracy. Using fully automated inspection recipes based on your tolerances and thresholds, the system identifies defective parts and can reject them immediately. Our software is designed so that key performance indicators (KPIs) and information are readily visible, ensuring you always have a clear overview of your production performance.

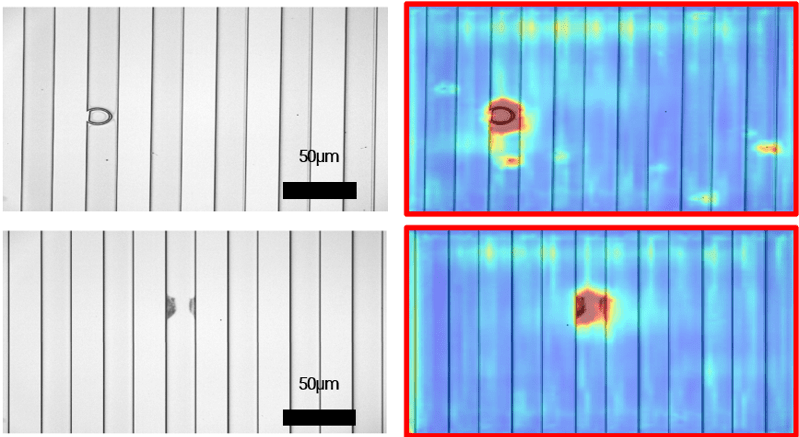

Defect detection

The MICRO.SPECTOR is specialized for processing large amounts of data. We have designed our software so that even at higher resolutions, where data can quickly exceed 40 billion pixels, our systems won't falter. For defect detection, we use either classic image processing or machine learning, depending on the application. For time-critical applications, we rely on highly efficient algorithms to perform quality control at the production cycle.

Where do we test?

Tell us

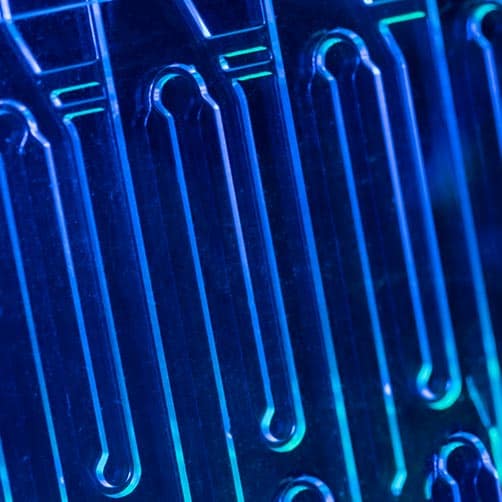

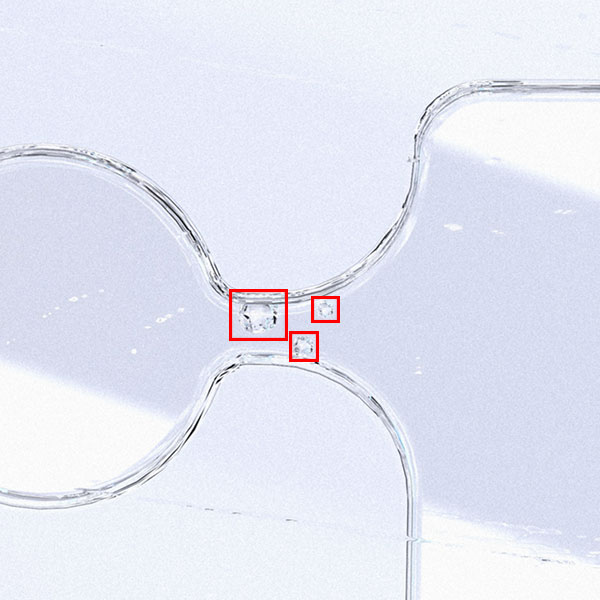

Microfluidics

Quality control of lab-on-a-chip systems or microfluidic chips

Microstructures

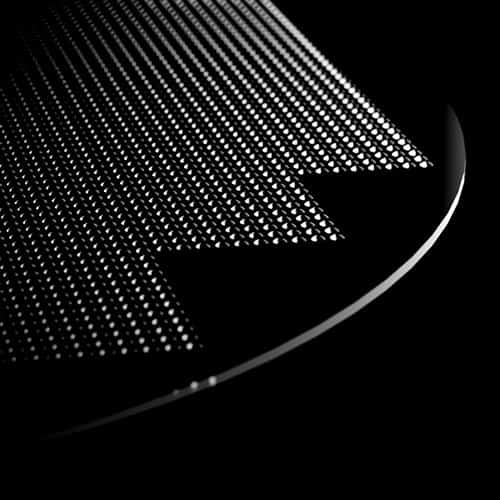

QC of microstructures on wafers, electroforming, metal surfaces

Laser micromachining

QC of microstructured components, holes, edges, shapes

Micro injection molding

QC of the smallest injection-molded components and structures

What are we testing?

Tell us

Defects

Blisters, scratches, cracks, closures, skin, particles, spikes, dust...

Dimensional accuracy

Channel widths, shape accuracy, roundness, continuity, spacing,...

presence

Missing or incomplete structures, incorrect placement

FAQs for the MICRO.SPECTOR

How quickly can the system check?

It depends entirely on your application. Often, the optimal balance between resolution and speed needs to be found. With some solutions, we can inspect entire components within a few seconds, while with other high-precision laboratory applications, inspection times can be significantly longer.

Which tests are covered by the MICRO.SPECTOR?

The MICRO.SPECTOR is based on machine vision systems using matrix and line scan cameras. Our focus is therefore on 2D inspections. If you require 3D inspections, please contact us. We also offer solutions with chromatic confocal line sensors or profile cutting systems.

I need a scalable solution, do you offer something like that?

Yes, in addition to the testing system, we build automation solutions for loading the system and also for transporting the components. The systems are designed so that they can be operated in parallel. This allows for any scalability.

Can I configure my exam on the system myself?

We are working on creating a platform where our customers can implement virtually any type of test. Currently, the systems are designed so that the tests are implemented by our experts and thoroughly tested for functionality. This allows us to guarantee the performance of the QC.