Logistics, pharmaceuticals, automotive

High-speed complete solutions for 1D and 2D data codes

MABRI.VISION specializes in the development and construction of sophisticated, turnkey solutions. Learn more about our systems for reading and verifying 1D and 2D data codes in production.

What are we testing?

1D codes

2D codes

Quality features

Flexible number and image fields

Modularly adaptable image fields enable the identification of multiple codes in one step.

Various surfaces and print images

Our system is suitable for both classic and color code printing as well as dot codes, laser-etched codes and various surfaces such as metal.

Complete system with application development

We offer complete application development and commissioning, as well as service and maintenance. We also respond to your individual customer requirements.

Advantages and special features

Complete solution for demanding Datacode applications

Belt speeds up to 800 m/min

Verification of all quality characteristics, testing according to ISO/IEC 15415 / 15416 and ISO/IEC TR 29158

High reading rates, even under difficult conditions

Data storage, measurement reports and documentation images

One camera system can replace several individual readers

Autofocus system for various objects

Custom applications

Interface to your ERP and production system

Flexibly adaptable test recipes, managed in databases

Supported formats

Here you will find a selection of supported code formats. Further variations are possible or can be implemented.

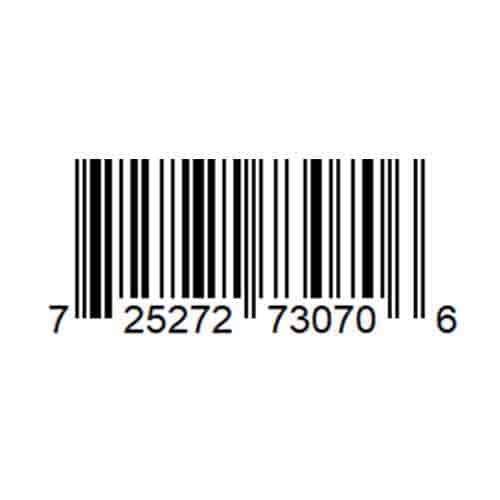

1D codes

GS1 DataBar Stacked Omnidir

2/5 Industrial

PharmaCode

Code 39/93/128

GS1 Aztec Code

EAN

GS1 DataBar Expanded Stacked

UPC-A/E

and more

2D codes

Aztec Code

QR code

Data Matrix ECC 200

GS1 QR Code

GS1 Aztec Code

Micro QR Code

GS1 DataMatrix

PDF417

and more

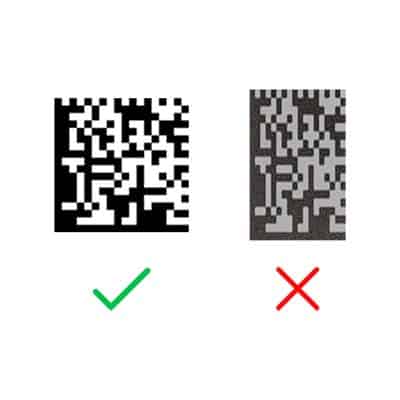

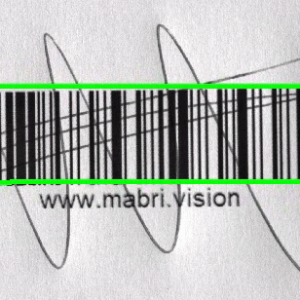

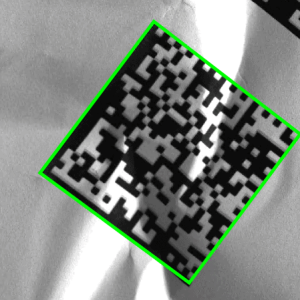

Robust code reading

Various challenges can arise in everyday industrial use when reading codes. A robust and reliable reading system is key to minimizing downtime and ensuring continuous product traceability.

Defocused

Covert

Dirty

Low contrast

Distorted

Destroyed

Wrinkled

Surfaces

Excerpt from quality parameters according to ISO/IEC 15415 and ISO/IEC 15416:

Axial unevenness

Lattice irregularity

modulation

Symbol contrast

Defects

Irregularities in the grayscale profile or within the quiet zone.

Decodability

Evaluation of line width and line spacing in relation to the ideal width.

Edge contrast

Minimum value between two adjacent lines.

reflection

Check if the lines are dark enough compared to the spaces between them.

Applications and implementations

Reading 2D codes on tires

Reading 2D codes from postage stamps

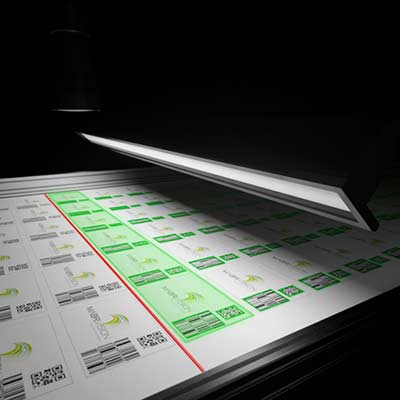

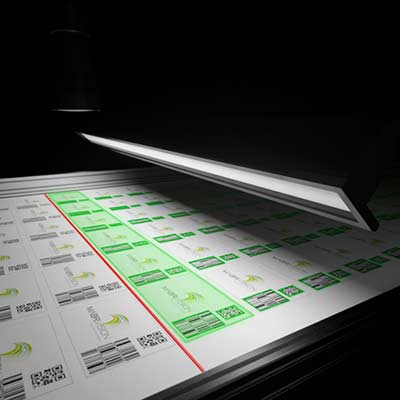

With the introduction of 2D codes for tracking and counterfeit protection of postage stamps, the need arose for seamless documentation of all codes from production to delivery. MABRI.VISION provides solutions that allow printing companies to perform 100% inspection directly on the paper web without impacting cycle time.

1D/2D code verification of tape products

Reading and verifying 1D and 2D codes for logistics centers and printing plants requires reliable reading at very high speeds. Additionally, assessing print quality is becoming increasingly important. The inspection platforms from MABRI.VISION GmbH offer the ideal solution for demanding logistics tasks and enable reading at belt speeds well over 500 m/min.

Reading units in reverse vending machines

We have already demonstrated our expertise in code and OCR recognition in the field of reverse vending. Various technologies are combined in a single system to ensure fast and accurate inspection of bottles and empty containers such as beverage crates. MABRI.VISION is already an approved ALE (reading unit) provider of DPG Deutsche Pfandsystem GmbH and is aiming to expand its portfolio to include QS (quality assurance) units in the near future.

UDI code detection and tracking

UDI codes serve for the unique identification of products using numerical or alphanumeric codes assigned by manufacturers to specific medical devices. They facilitate the clear and unambiguous identification of specific products, as well as traceability, medical device recall, the fight against counterfeiting, and the improvement of patient safety.

MABRI.VISION enables the rapid and reliable detection of UDI codes with simultaneous form, presence, and defect verification.

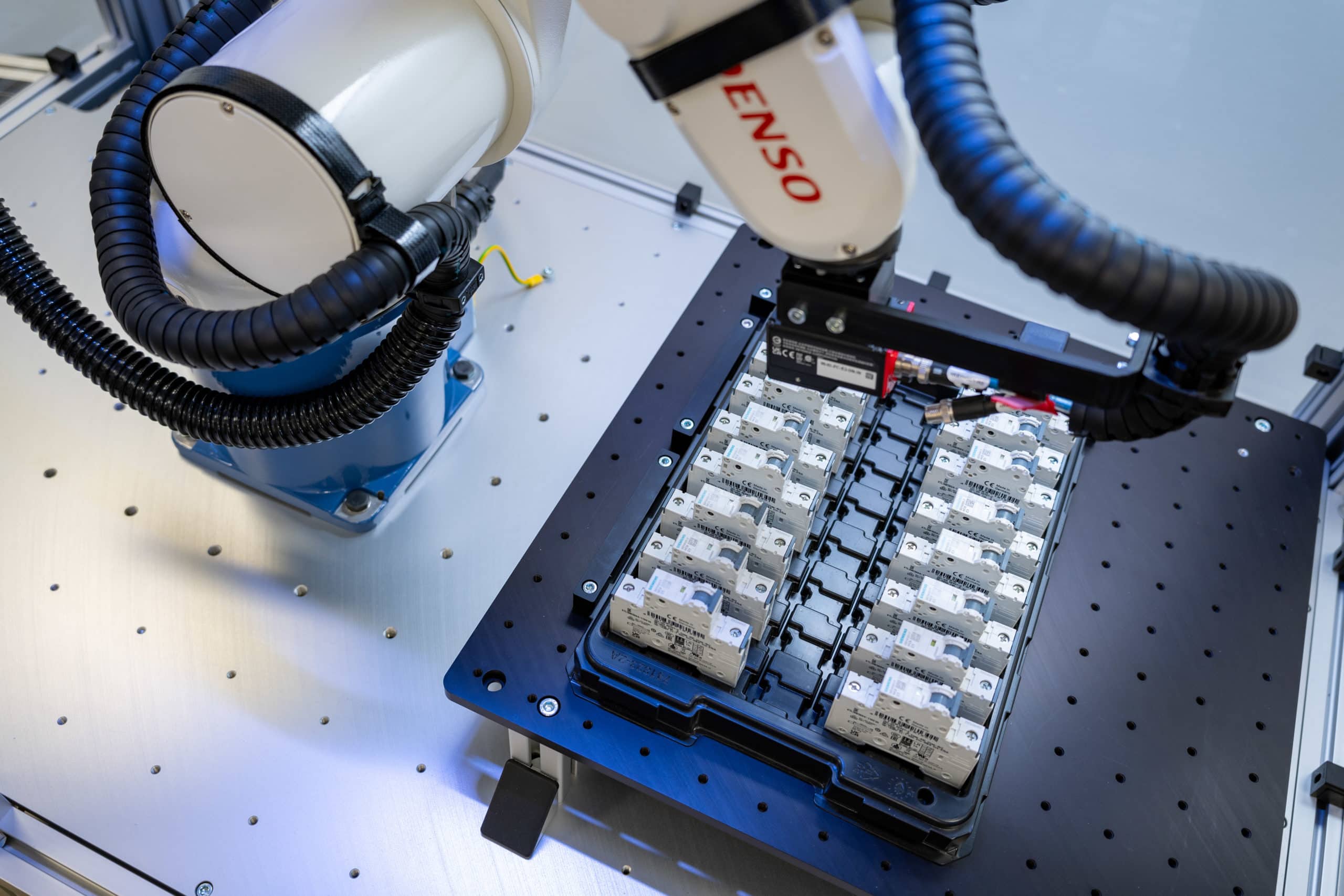

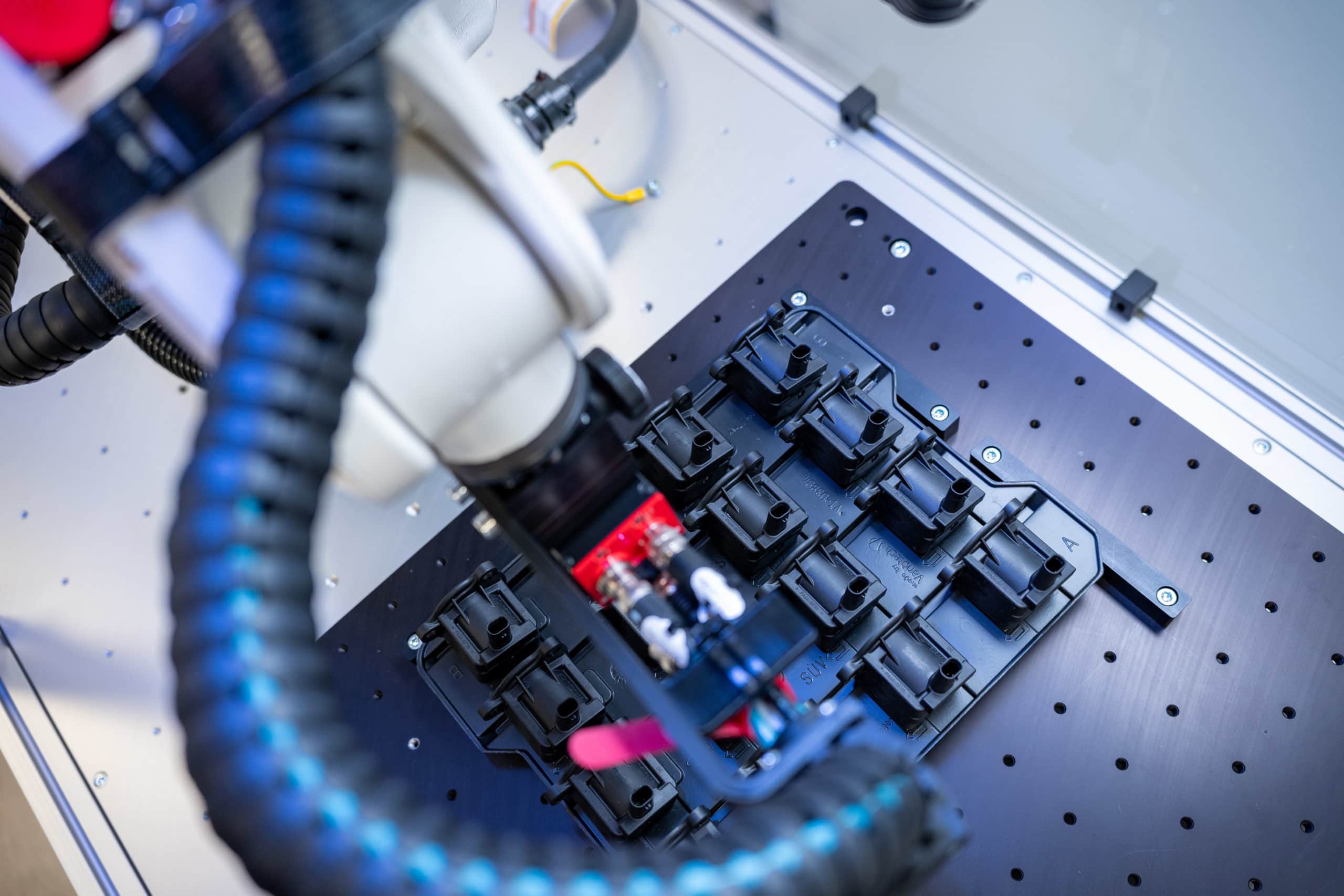

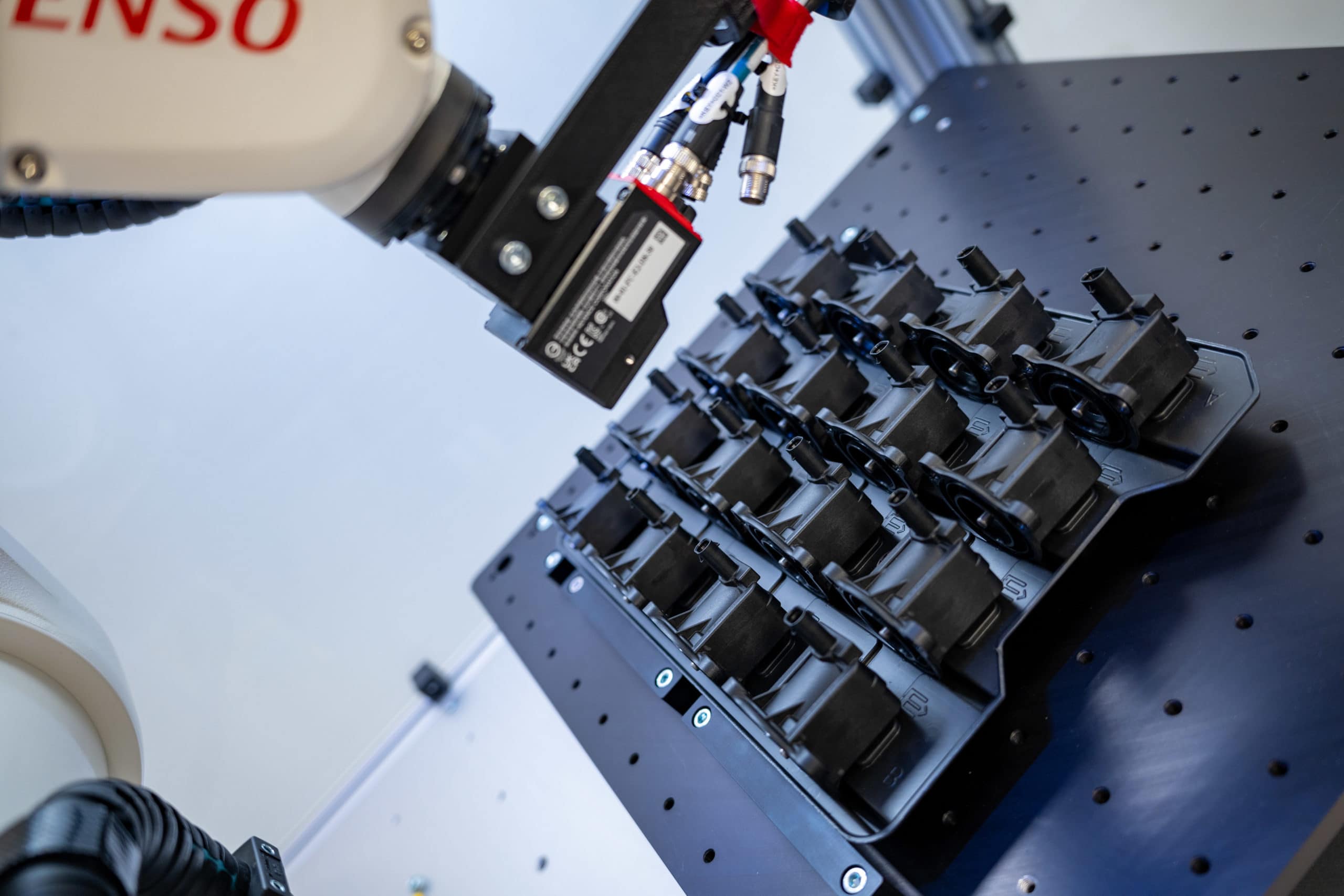

ROBOT.SPECTOR DMC

Robot-guided Data Matrix code verification

The ROBOT.SPECTOR DMC from MABRI.VISION is a Data Matrix Code Verifier designed for the detection, verification, and classification of various code types. This version specializes in Data Matrix codes. With robot-guided sensors and AI-based image analysis, it enables precise inspection even on complex surfaces and from different angles. This technology delivers fast, reliable results for industrial quality assurance, meeting specific customer needs through flexible sensor technology integration. The system provides an efficient solution for quality control and ensures high accuracy in code verification.

software

Modular

MABRI.VISION software is designed modularly. In addition to a wide range of standard components, we are happy to extend the software with suitable modules for your application. All common interfaces are available for seamless integration into your production process.

Databases

The MV.IMAGING software supports your quality assurance through the use of databases for production orders and recipes. The database interface is tailored to the specific requirements of your tests and evaluations. All data can be exported as structured test reports in .csv, .xls, or .pdf format.

Statistics / Analysis

Our software platform offers a wide range of visualization options. Meaningful statistics help you maintain an overview of production processes and quality assurance. Our software experts are familiar with the specific requirements of various industries and design the software with insightful key performance indicators and useful tools such as good part counters, error and measurement image storage, and early warning limits for process support.