MV.EYE PL1

Inspection of the shape and defects of castings

MV.EYE PL1

Inspection of the shape and defects of castings

Applications

- Inspection of castings

Exams

- Defects

- form

- presence

- volume

Industries

- Automotive

- Metalworking

- Lightweight construction

Surface pores

The MV.EYE PL1 system enables the detection of surface pores and cavities on functional surfaces that can occur during the aluminum die casting process.

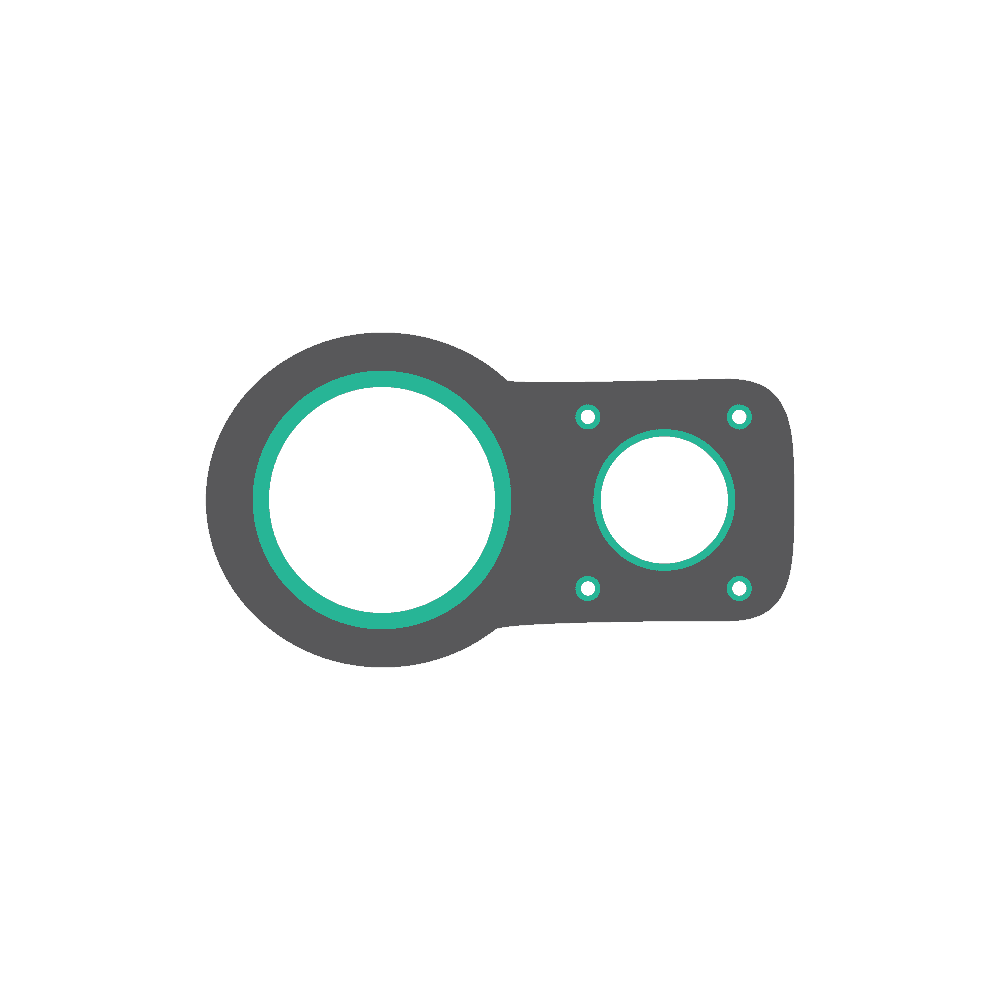

Form test

Rely on the MABRI.VISION inspection system for comprehensive form testing of your components. Benefit from optimization through stored and analyzed data.

Flaws & Defects

Our MV.EYE PL1 inspection system ensures fast and reliable detection of flaws, grooves, scratches and dents on functional and cast surfaces.

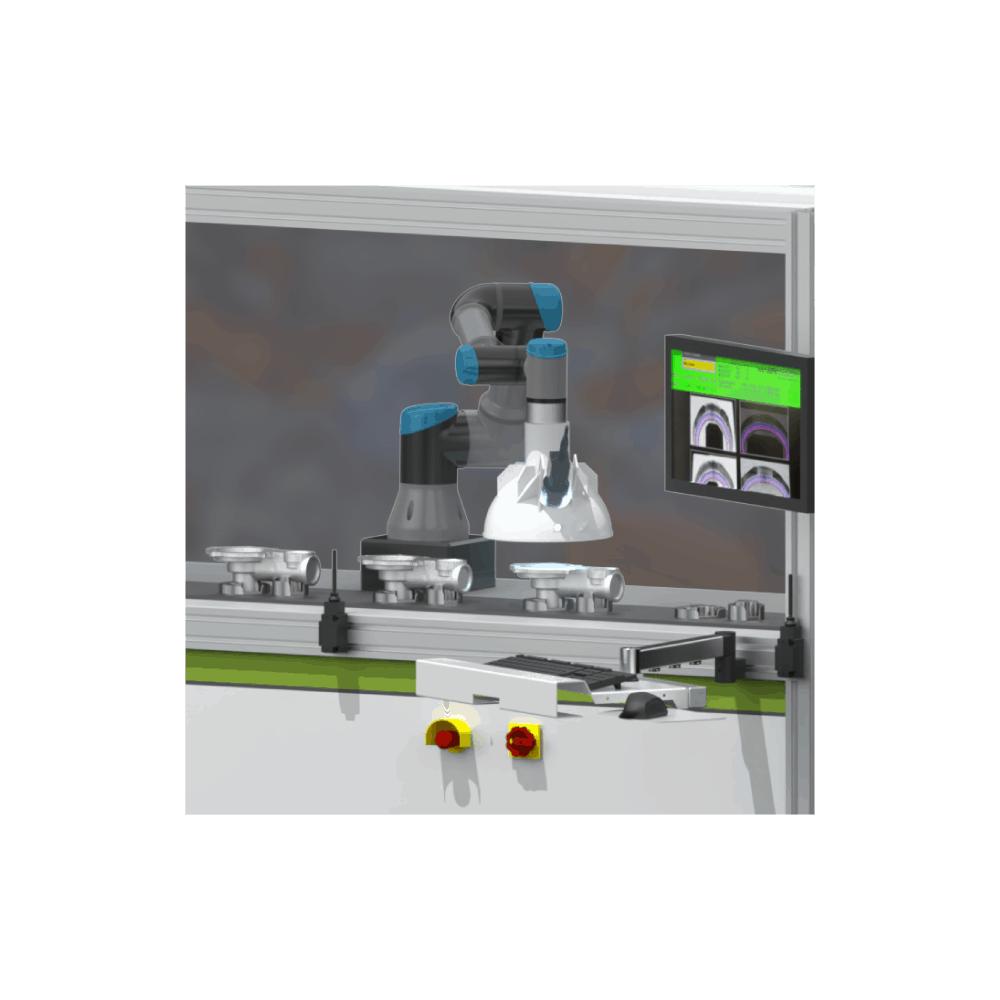

robot-guided sensors

Robot-guided sensors enable the inspection of components from different perspectives. The use of gripper arms allows for the immediate sorting out of damaged components.

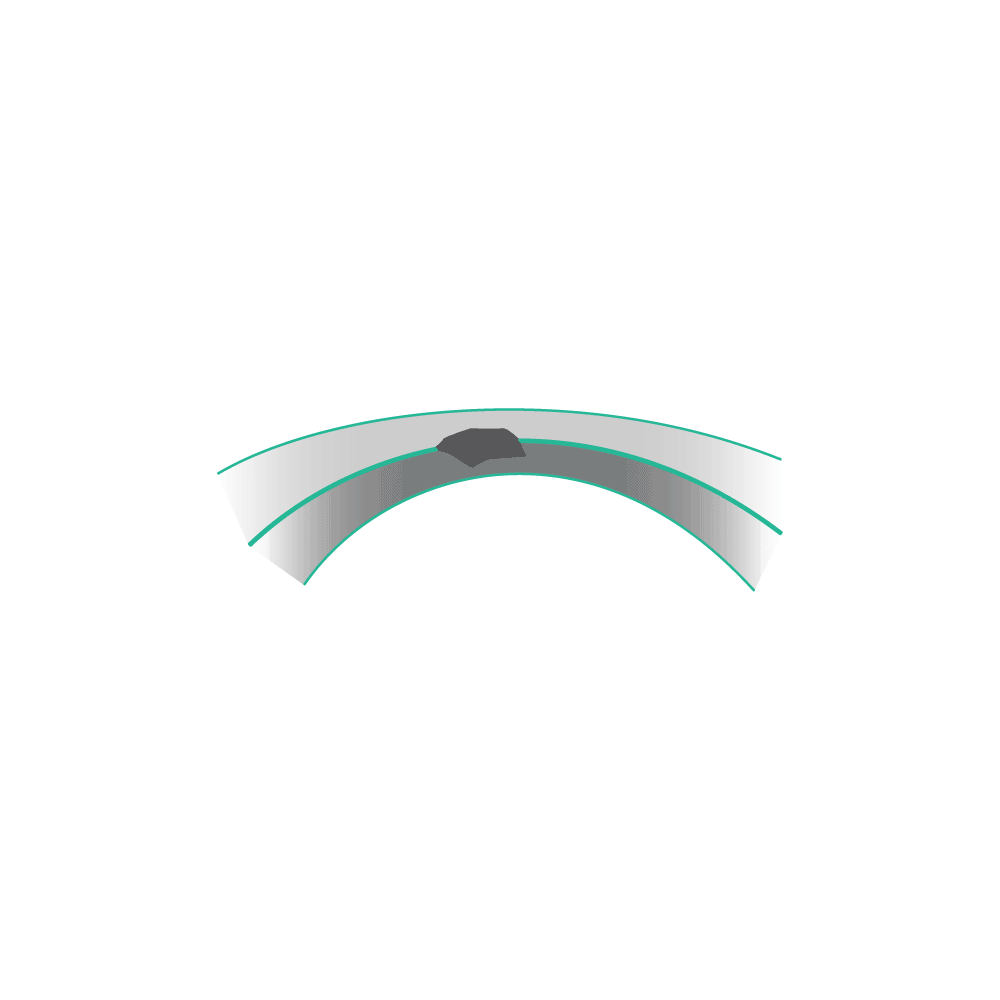

areas that are difficult to access

Thanks to the use of special optics, the MV.EYE PL1 inspection system can also inspect hard-to-reach surfaces. Internal surface pores are detected in a 360° view.

Process integration

The inspection of relevant characteristics takes place in sync with the production cycle and can therefore be seamlessly integrated into your production line. Our MV.EYE PL1 system offers all common industrial interfaces.

Specifications

Universal: versatile in its applications

Metalworking

The MABRI.VISION testing system is ideally suited for testing castings at high speed and for detecting surface pores, flaws and defects.

Lightweight construction

Benefit from inline-capable inspection of shapes, tolerances, and defects in lightweight construction. Even hard-to-reach areas are captured quickly and with high precision.

automobile

In the automotive industry, the MV.EYE PL1 testing system is used due to its fast measurement cycle and seamless integration into automated production processes.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision