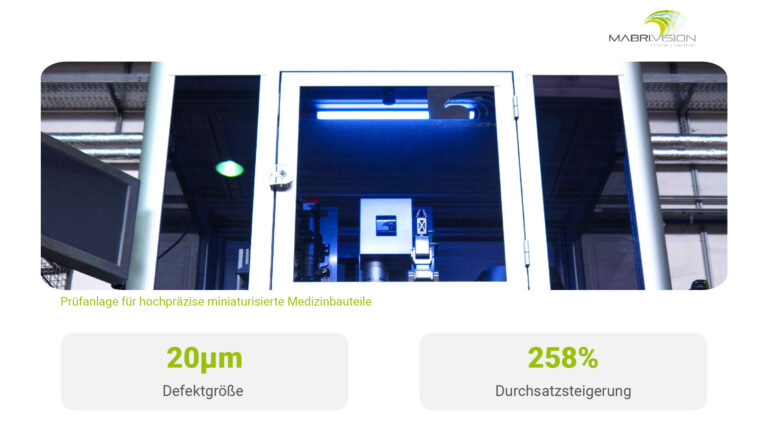

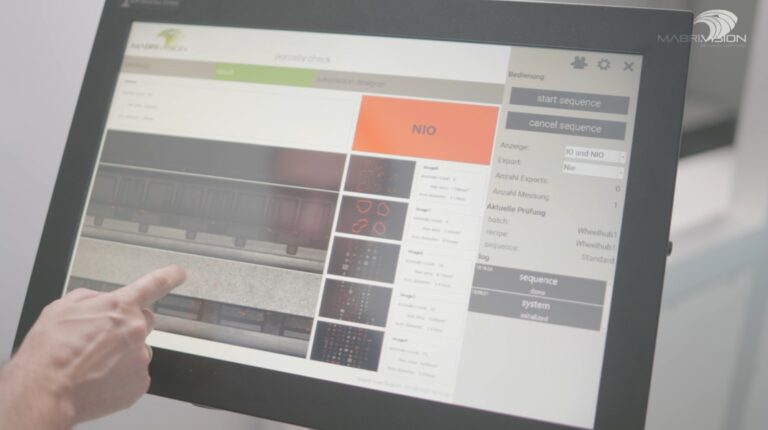

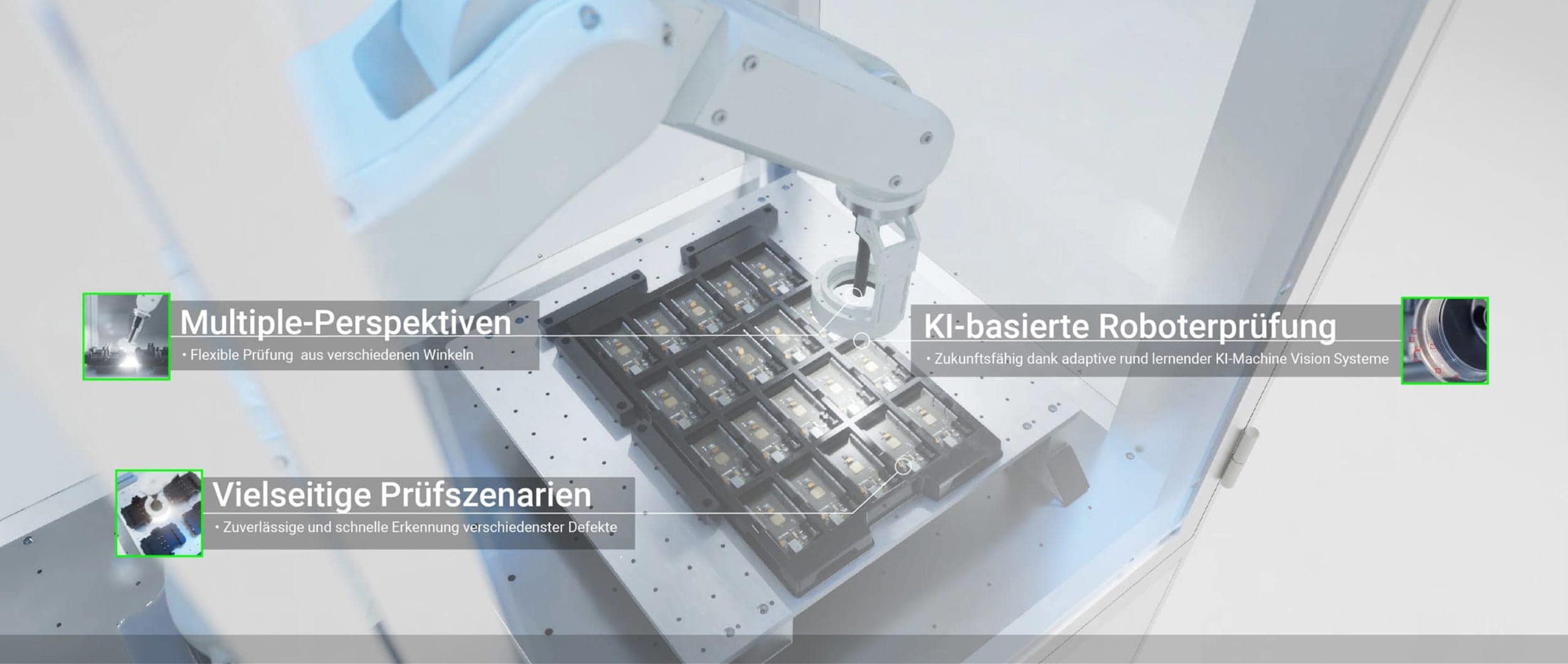

Live demo: Automated image processing system from MABRI.VISION at the VDL Steelweld plant

You are currently viewing placeholder content from the standard version. To access the actual content, click the button below. Please note that this will involve sharing data with third parties. Unlock content Accept required service and unlock content More information Intelligent inline inspection – How VDL Steelweld ensures quality with MABRI.VISION Experience our VISION.SPECTOR live in…