Medical technology, pharmaceuticals, life sciences

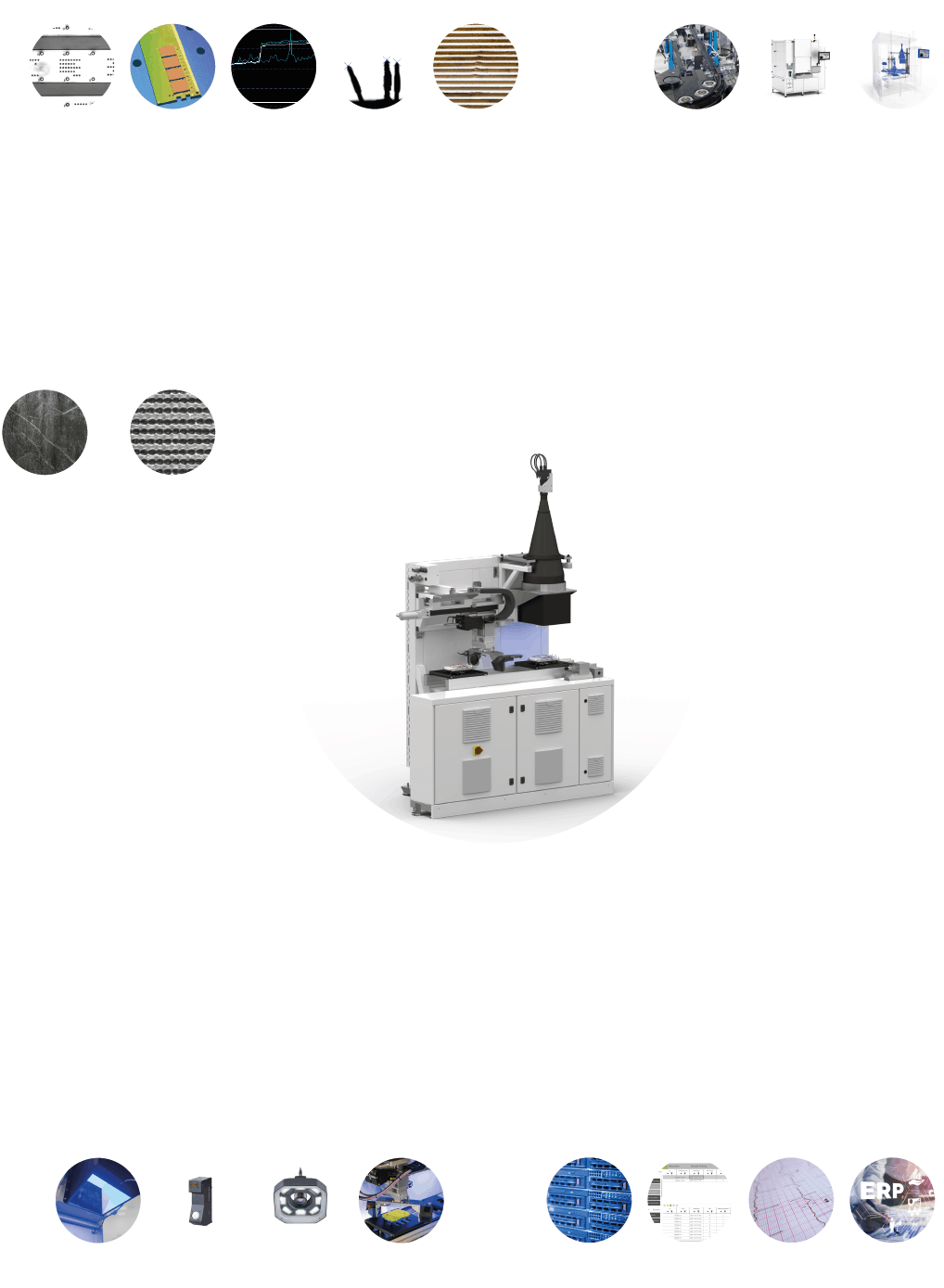

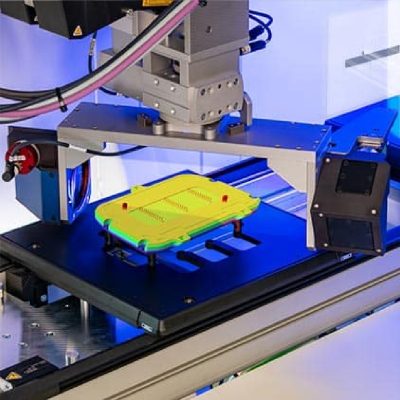

Inline 2D/3D measurement on the workpiece carrier MV.EYE i2 WT

Non-contact 100% production control in the production cycle

With the MV.EYE i2 WT inspection system, MABRI.VISION offers an inline-capable vision solution for seamless quality inspection in your production line. The inspection system enables non-contact testing of 2D and 3D component features and can be easily integrated into existing systems using standard industrial interfaces. Key features of the system include the high speed of the inspection processes, which allows for testing in sync with production cycles, and its modular design. MABRI.VISION experts utilize state-of-the-art technologies in the design of the inspection system. By combining 3D surface inspection, large-area telecentric 2D inspection, and 2D & 3D inspection with an optical micrometer, 100% inspection of your components is achieved. The unique aspect of combining different inspection sensors is that the inspections are not viewed independently. By transferring the data to a common coordinate system, highly precise results can be delivered.

Replace your CMM testing processes with the MV.EYE i2 WT inspection system and achieve a significant acceleration of your quality assurance. You benefit from an inspection system that supports your production through automation and comprehensive evaluation options.

The testing system for automated production processes

The MV.EYE i2 WT inspection system is designed for fast, optical inline testing in real time. Through high-speed testing and the use of parallelization mechanisms, the system supports your production with an efficient testing process.

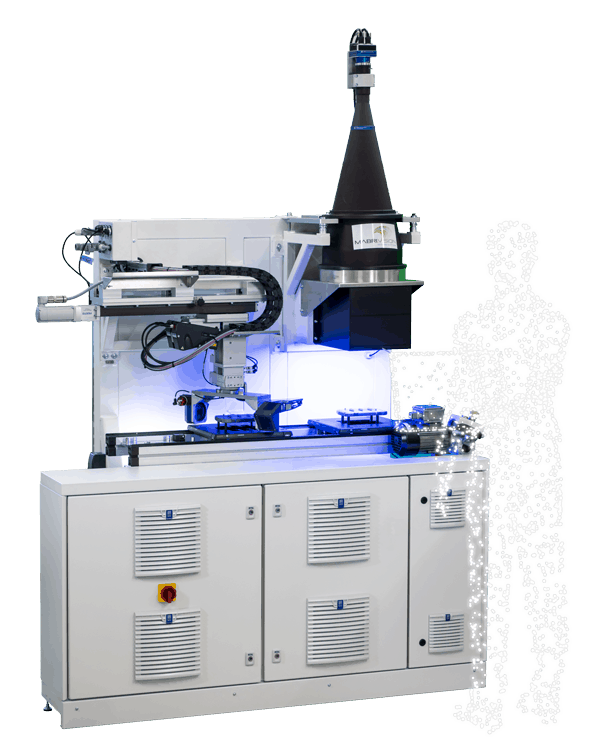

Feature fusion from 3 measuring stations

MABRI.VISION not only uses different sensors and testing methods in the MV.EYE i2 WT testing system to check the characteristics of your components, but also combines the obtained test data and calculates the coordinate systems for optimal test results.

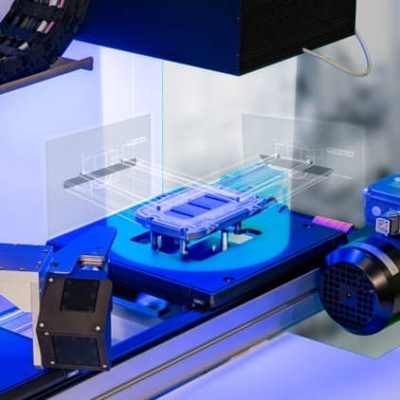

Production processes in a cleanroom

The MV.EYE i2 WT testing system is suitable for use in cleanrooms across various industries, such as medical technology and pharmaceutical production. Our software is designed for integration with ERP systems. The testing system can be equipped with an enclosure and a cleanroom filter and can be integrated into your production line via standard interfaces.

Combination of 2D and 3D testing methods

To meet our customers' required inspection protocols, we integrate various sensors into the inspection system. Frequently used are the combination of laser triangulation and an optical micrometer for 3D feature recognition and large-area telecentric vision systems with cameras for 2D feature acquisition.

Consistently precise results

We supply standard calibration standards compliant with ISO 10012, with traceability to national calibration standards. All our calibration standards originate from DAkkS-certified testing laboratories and come with a corresponding calibration certificate. The MABRI.VISION software supports you in the regular testing of your measuring system as part of your test equipment monitoring. No expert knowledge is required to perform the test.

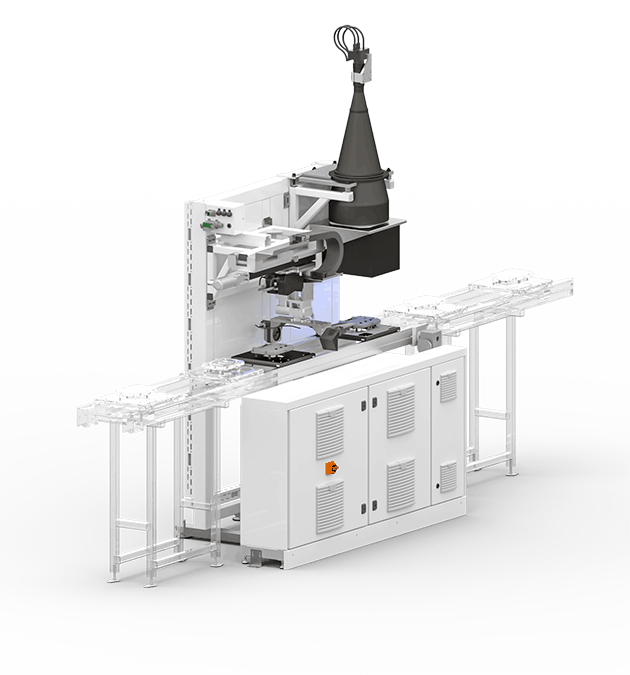

Clock-time-neutral high-speed testing

The use of workpiece carrier systems enables a particularly high inspection rate. With the MV.EYE i2 WT inspection system, you can perform continuous inspections at a production cycle of less than 5 seconds. With 24/7 production, this means that over 5 million parts per year pass through the inspection system.

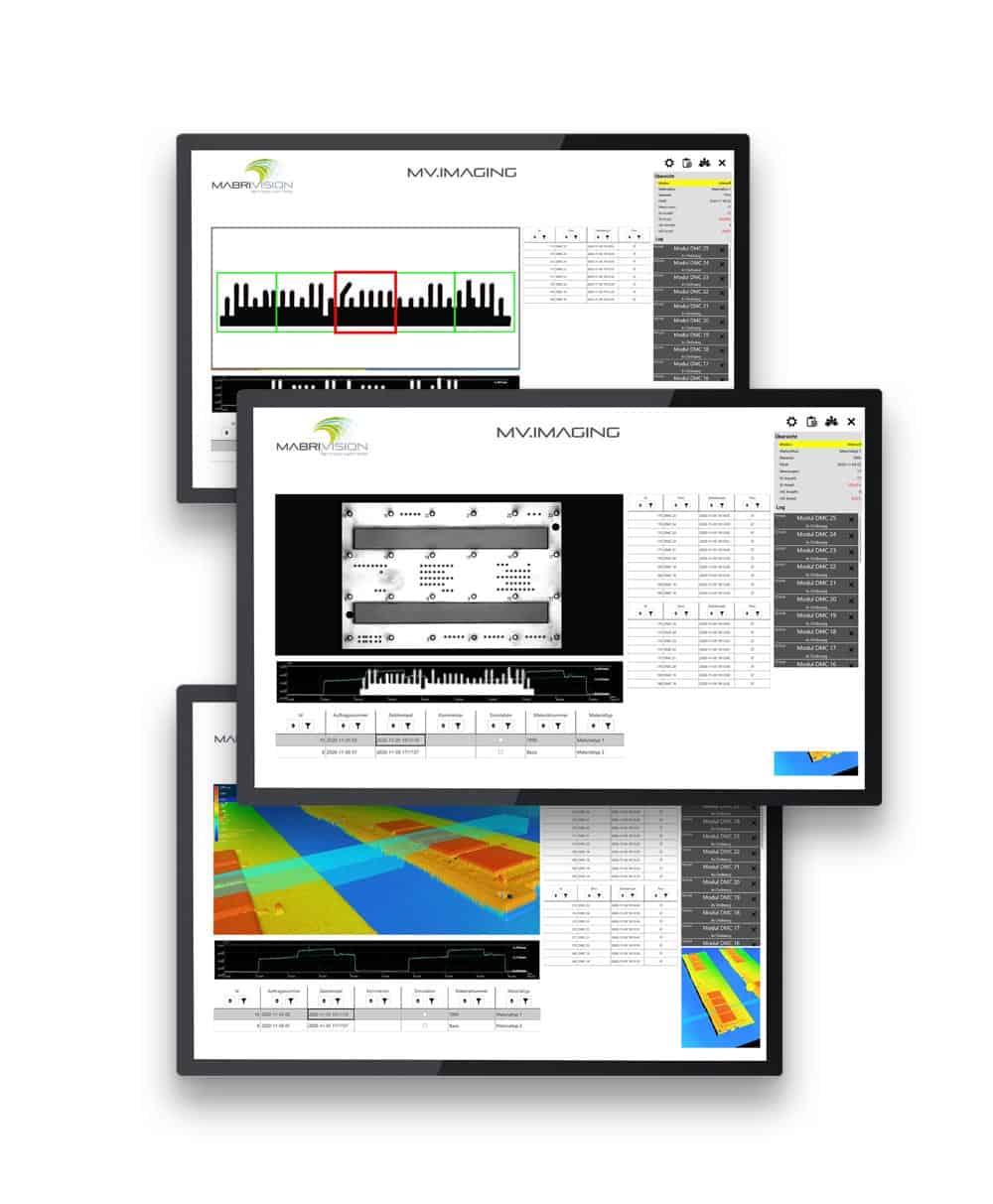

software

Through numerous projects across diverse industries, our software is tailored to industrial needs. The software platform offers a wide range of visualization options, enabling you to maintain an overview of production processes and quality assurance through insightful analyses. Even with complex testing tasks, MABRI.VISION software employs efficient programming to ensure analysis is performed in sync with your production cycle.

Intuitive user interface

Made for production

We achieve the balance between industrial software and a modern user experience by combining various platforms and technologies in our framework. This allows us to map real-time processes and the familiar Windows environment into a single system. As a result, you can operate our testing systems efficiently and with minimal training. Features include:

- Process indicators and visualization of relevant results

- Seamless tracking through result exports and databases

- Batch management

- Calibration and evaluation options

- Integration through all industry interfaces

- Advanced user management with audit trail

Artificial intelligence

Modular design

The demands of modern production environments are diverse and challenging. No two complex manufacturing processes are alike – which is why adaptable solutions are particularly needed for quality control. The MABRI.VISION MV.EYE i2 WT inspection system is designed to be modular and adaptable to your specific production conditions.

You benefit from a variety of 2D and 3D inspections. 2D measurements, for example, determine the presence of features and their exact positions. Furthermore, defects such as scratches or discoloration can also be detected.

Advantages of 2D inspections include high speed and robust data acquisition. 3D measurements generate precise height information and determine dimensional accuracy in the lower micrometer range. The multimodality of the MV.EYE i2 WT inspection system enables its use in various industries and is particularly appealing where individual solutions fail due to complexity.