Ihre Lösung für effiziente DOT-Code-Lesung

Entdecken Sie mit VISION.SPECTOR TIRE DOT die Zukunft der automatisierten Qualitätskontrolle für Räder und Reifen. Unsere Prüfsysteme bieten flexible Anwendungsmöglichkeiten – perfekt geeignet für den Einsatz am Beginn der Montagelinie sowie zur abschließenden End-of-Line-Qualitätsprüfung. Ausgestattet mit der neuesten Machine Vision Technologie, garantieren unsere Anlagen eine akkurate Erfassung von DOT-Codes. Steigern Sie mit maßgeschneiderten Lösungen von MABRI.VISION die Qualitätsstandards und Effizienz Ihrer Produktionsprozesse.

Doppelte Perspektive, Maximale Zuverlässigkeit: Unser System ermöglicht eine umfassende Inspektion beider Reifenseiten ohne die Notwendigkeit einer Wendeeinheit. Dies verbessert nicht nur die Effizienz, sondern auch die Genauigkeit Ihrer Qualitätsprüfungen und minimiert Fehlerquellen.

VISION.SPECTOR TIRE DOT bietet eine vollständige Prüflösung, die speziell auf die Erfassung von DOT-Codes fokussiert ist. Reduzieren Sie die Notwendigkeit mehrerer spezialisierter Prüfstationen mit unserer integrierten Lösung.

Die Anlage nutzt einen Gurtförderer für den Transport der Räder durch das System, eine Zentrierung der Räder ist nicht nötig. Diese sanfte Handhabung minimiert den physischen Impact auf die Räder, während gleichzeitig eine präzise und effiziente Prüfung sichergestellt wird.

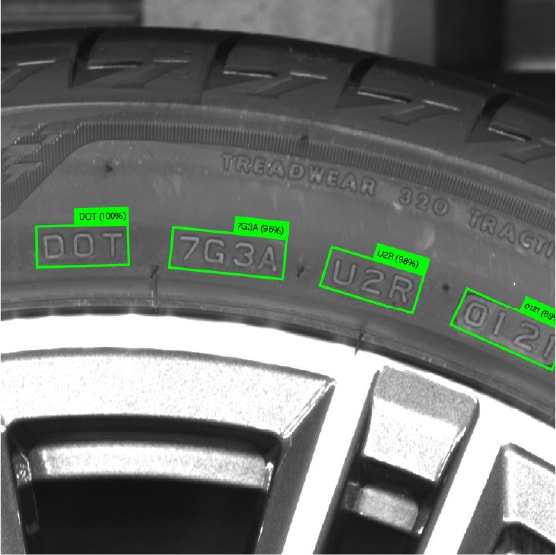

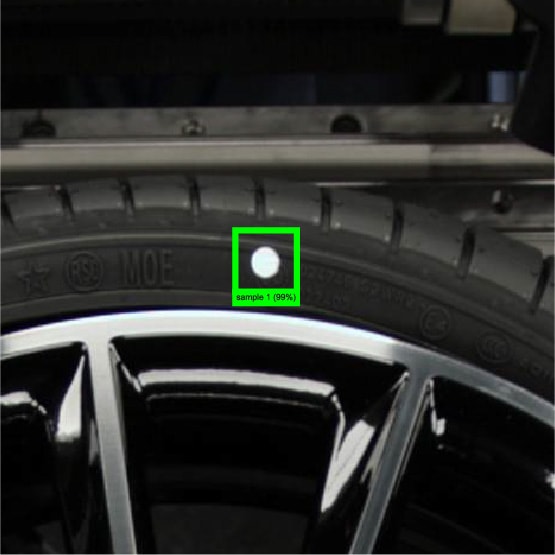

KI basierte Erkennung von DOT-Codes auf beiden Seiten: Durch den Einsatz künstlicher Intelligenz werden DOT-Codes auf der Außen- und Innenseite des Reifens präzise identifiziert, was eine vollständige Rückverfolgbarkeit und Compliance gewährleistet.

KI basierte Erkennung von DOM-Codes auf beiden Seiten: Durch den Einsatz künstlicher Intelligenz werden DOM-Codes auf der Außen- und Innenseite des Reifens präzise identifiziert. Diese Erkennung ermöglicht eine umfassende Rückverfolgbarkeit der Produktionsdaten und sorgt für höchste Compliance und Qualitätssicherung in Ihrer Fertigung.

Reifenbreite | 115 mm - 350 mm |

Reifenaußendurchmesser | 500 mm - 850 mm |

Niederquerschnittsverhältnis | 20 - 95 % |

Laufrichtungsgebundene Räder | Ja |

Mischbereifung VA/HA | Ja |

Allwetter | Ja |

Run flat | Ja |

Winterreifen | Ja |

Anzahl Varianten | Ca. 9999 |

Anzahl Hersteller | Ca. 999 |

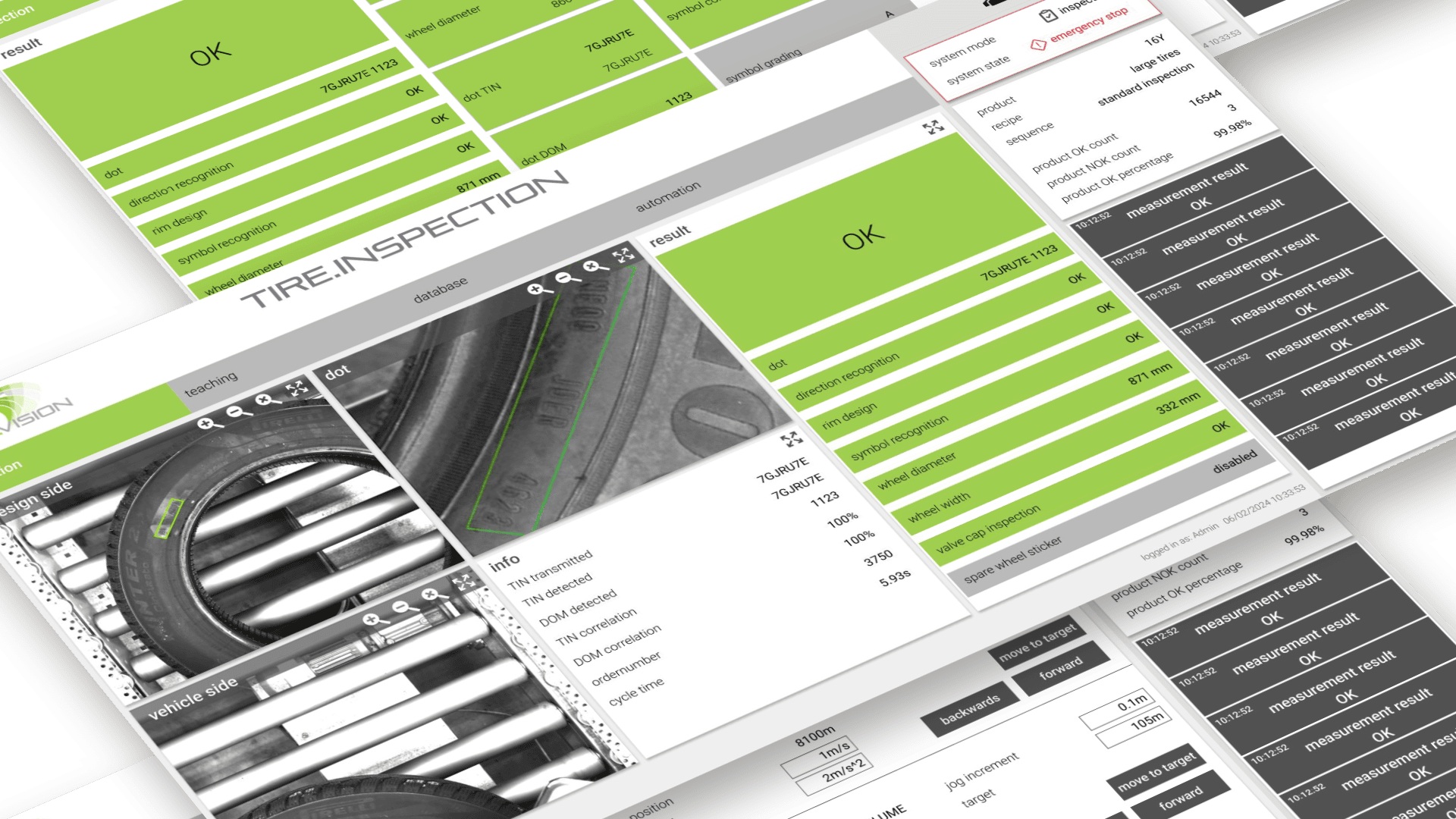

Die Machine Vision Software des VISION.SPECTOR TIRE DOT ist eine Lösung für die automatisierte Prüfung von DOT-Codes. Mit ihrer Fähigkeit, präzise DOT-Codes zu identifizieren, vereint sie Effizienz mit Genauigkeit. Die intuitive Benutzeroberfläche auf einem großen Bildschirm ermöglicht eine leichte Bedienung und schnelle Anpassung an verschiedene Prüfaufgaben, während das integrierte Datenmanagement die Rückverfolgbarkeit und Qualitätskontrolle verbessert. Optimieren Sie Ihre Produktionslinie mit einer Software, die für Präzision in der End-of-Line Prüfung steht.

Egal ob in der Rädermontage, Reifen- und Felgenproduktion oder im Einlagerungs- und Ersatzteilgeschäft – VISION.SPECTOR TIRE DOT setzt neue Standards in der Qualitätskontrolle und fördert die Herstellung und das Handling einwandfreier Produkte.

Die VISION.SPECTOR TIRE DOT Prüfanlage ist ein unverzichtbares Werkzeug für die Rädermontage, das durch hochpräzise KI-gestützte Bildverarbeitung die Qualitätssicherung optimiert. Sie ermöglicht eine schnelle und fehlerfreie Überprüfung der Montagequalität, optimiert den Montageprozess und steigert die Gesamtproduktivität.

In der Reifen- und Felgenproduktion setzt unser System Maßstäbe in der Qualitätskontrolle. Es identifiziert präzise jegliche Abweichungen und Unregelmäßigkeiten in Material und Design, sichert die Produktionsstandards und fördert die Auslieferung einwandfreier Produkte.

Für das Einlagerungs- und Ersatzteilgeschäft bietet die VISION.SPECTOR TIRE DOT Prüfanlage eine effiziente Lösung zur Qualitätskontrolle und Sortierung von Rädern und Reifen. Ihre Fähigkeit, Produkte akkurat zu klassifizieren, erleichtert die Lagerorganisation, verbessert die Zugriffsgeschwindigkeit auf Ersatzteile und minimiert Lagerhaltungskosten. Insbesondere für automatisierte Logistikkonzepte stellt die Anlage eine Schlüsselkomponente dar.

Entdecken Sie, wie unsere Machine Vision Prüfanlagen den Unterschied machen. Sprechen Sie mit einem Experten!

Copyright 2015 – 2024 MABRI.VISION GmbH | All Rights Reserved