ROBOT.SPECTOR

Robotergeführte Sensorik.

Robotergeführte Messtechnik.

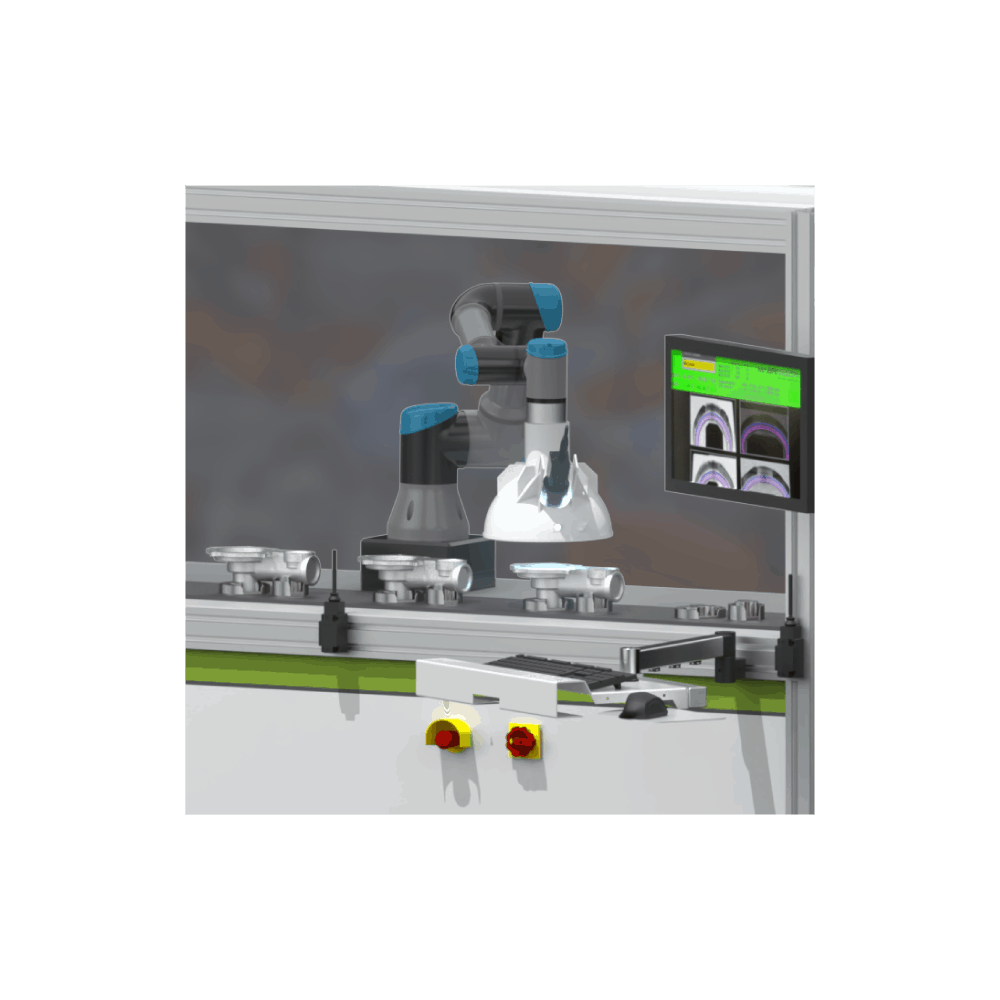

Durch die Nutzung robotergeführter Sensorik ermöglicht MABRI.VISION eine flexible und schnelle Prüfung mehrerer Perspektiven an einem Bauteil und gewährleistet somit eine lückenlose Qualitätskontrolle.

Der Roboter kann dabei mit unterschiedlichen Prüftechnologien ausgestattet werden, wie beispielsweise hochauflösenden Kameras oder Triangulationssensoren. So können Ihre speziellen Prüfanforderungen bestmöglich erfüllt und auch schwer zugängliche Bereiche von Bauteilen im Prozesstakt geprüft werden.

Multi-Prüfstellen.

Die Robotik ermöglicht eine unkomplizierte Prüfung der Bauteile aus unterschiedlichen Perspektiven. Dabei wird die Technologie eingesetzt, die Ihre Prüfmerkmale bestmöglich erfasst.

Beliebige Orientierungen.

Prüfen Sie Ihre Bauteile oder Erzeugnisse unabhängig der Lage: durch robotergeführte Sensorik können trotz Prüfung im Produktionstakt alle Prüfmerkmale erfasst werden.

Kollaborative Arbeitsplätze.

Ob zur Sortierung oder dem Griff des Prüfteils: vollautomatisches Entnehmen von Teilen durch einen Greifarm bietet erhebliche Kosten- und Zeitersparnisse in Produktions- und Prüfprozessen.

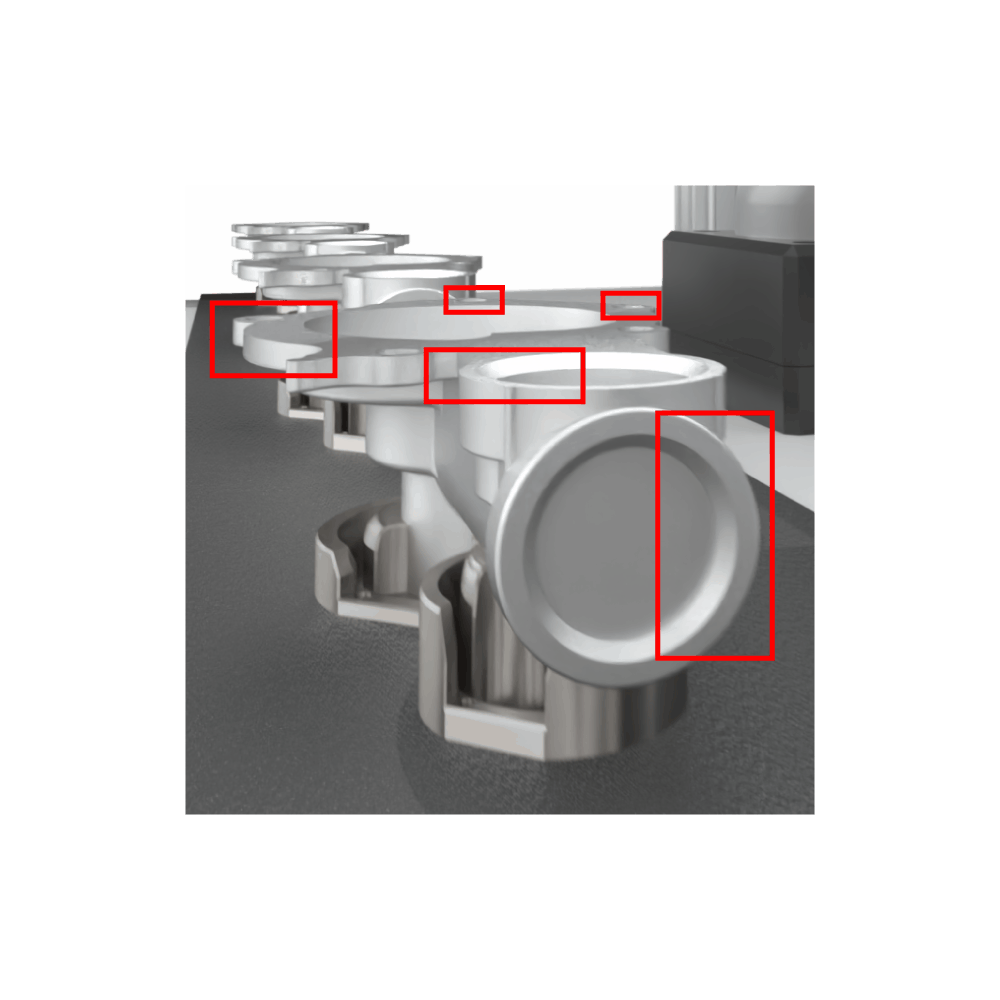

Maßhaltigkeit.

Kompromisslose Prüfung der Maßhaltigkeit aus verschiedenen Winkeln. Optimieren Sie Ihre Produktion durch eine 100%-Prüfung von Bauteilen und Erzeugnissen.

Defektprüfung.

Zuverlässige und schnelle Erkennung von Defekten und Verschmutzungen. Durch den Einsatz von Greifarmen können beschädigte Bauteile umgehend aussortiert werden.

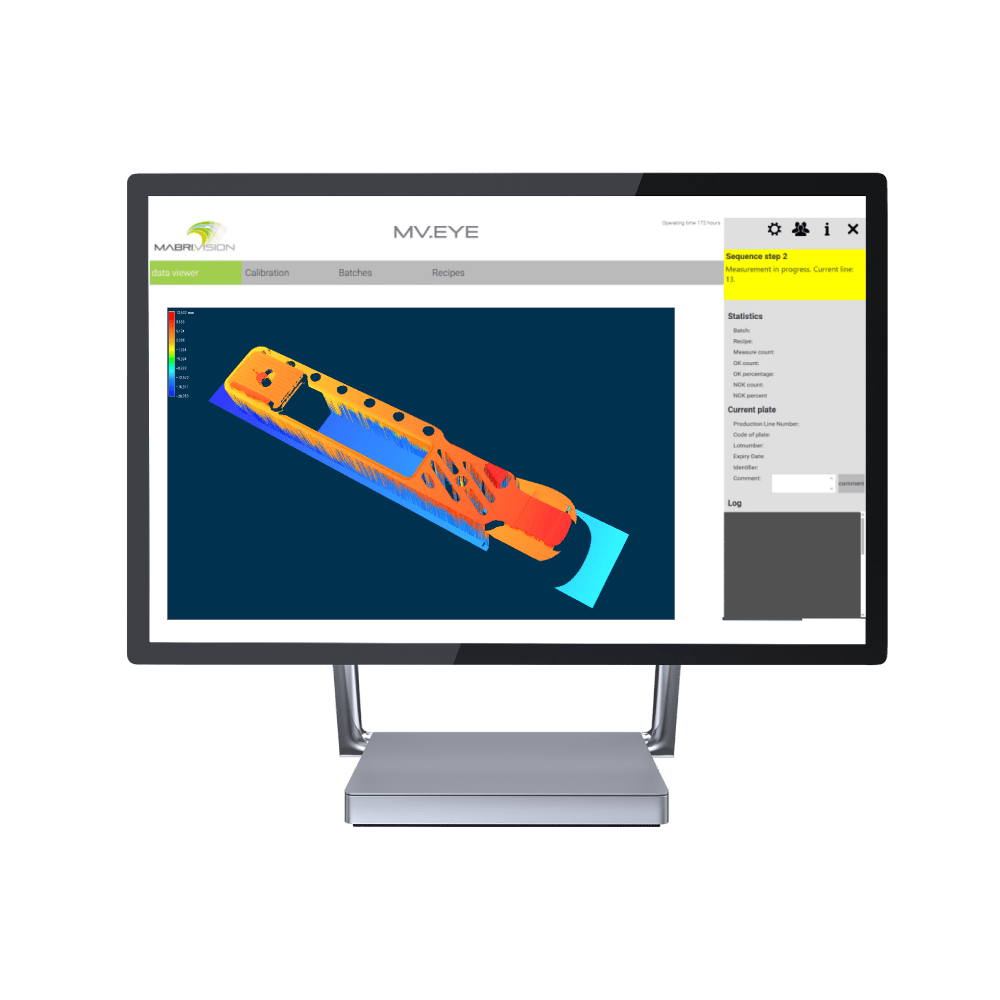

3D-Prüfung.

Ihre Prüfanforderungen bilden unseren Maßstab. Wir kombinieren auf Ihren Wunsch hin die robotergeführte Sensorik mit modernsten Technologien zur 3D-Prüfung.

Universell: vielfältig einsetzbar.

metallverarbeitung

Gehen Sie bei der Qualitätskontrolle keine Kompromisse ein und bleiben Sie auch bei schwer zugänglichen Bauteilen flexibel.

kunststofftechnik

Von der Prüfung bis hin zur Identifizierung und Sortierung von Teilen: gestalten Sie Ihre Produktion durch Robotik effizienter.

automobilindustrie

Flexibilität und Kollaboration bilden im Automobilbereich die Grundlage für Produktion, Prüfung und Montage.

elektrotechnik

Präsenz, Lagetoleranzen, Taumelkreise – die Prüfungen im Bereich der Elektrotechnik sind vielfältig und durch Robotik realisierbar.